Statement of problem: An optimal marginal and

internal fit plays an important role in the longevity

of a restoration. Increased marginal gaps can cause

bacterial and biofilm adherence. Also, poor internal

fit can lead to decreased retention and resistance

form. There are various techniques available for

the fabrication of restorations. All these techniques

have their own pros and cons. In regards to these

problems, the present study was conducted to find

out whether the manufacturing technique has any

influence on the marginal and internal fit of copings.

Aim: The aim of this study was to evaluate and

compare the internal and marginal fit of Co-Cr

copings fabricated by three different techniques

namely, conventional lost wax technique, 3D resin

printing technique and CAD/CAM milling technique.

Materials and methods: A stainless steel master

model and a custom tray were fabricated. Totally 30

impressions were made and poured with die stone

to obtain 30 die specimens. The specimens were

grouped into three groups. Group 1- conventional

lost wax technique, group 2- 3D resin printing

technique and group 3- CAD/CAM milling technique.

Co-Cr copings were fabricated using the respective

technique. For evaluating the internal fit, weighing

technique was followed. The cross-sectional

technique was followed to assess the marginal fit.

Results: There was statistically significant

difference between the different groups in terms

of internal and marginal fit. The CAD/CAM milling

technique showed better marginal and internal fit

compared to the other two techniques. The 3D resin

printing technique showed better results than the

conventional technique but was not statistically

significant.

Conclusion: Within the limitations of this present

study, the results drawn suggests the use of CAD/

CAM milling technique and the 3D resin printing

technique for fabricating restorations in routine

dental practice.

Key words: marginal fit, internal fit, cobalt-chromium alloy, coping, scanning electron microscope.

Metal ceramic restorations are one of the most

sought out options for fabricating full-coverage

crowns and fixed partial dentures1

. An accurate

marginal and internal fit of cast restorations plays

a vital role in the longevity of the restoration.2

The precision of fit of a restoration is determined

by two criteria: the marginal and the internal

fit. The marginal fit provides a proper seal and an uniform internal fit provides an appropriate

cement space which is necessary for good retention

and resistance of the restoration.3

Holmes et al

defined the internal gap as the measurement

between the axial wall of the prepared tooth and

the internal surface of the casting, while the same

measurement at the margin is called marginal

gap.4

McLean and Fraunhofer in 1971, after clinically

examining 1000 metal ceramic crowns, reported

that marginal discrepancies up to 120µm were

acceptable.5

Initially, gold alloys were considered as the

material of choice for the fabrication of metal

ceramic restorations. But the increased cost of the

gold alloys led to the use of base metal alloys as

an alternative.6

Ni -Cr alloys have been commonly

used for making metal copings. But they also

have their own limitations, due to increased oxide

formation and biocompatibility issues of nickel

and beryllium, they can cause allergic reactions

in many patients. Co-Cr alloys can be considered

as a good alternative to Ni-Cr alloys due to their

better biocompatibility, mechanical properties,

corrosion-resistance and also cost efficiency.7

The conventional technique of fabrication employs

the lost wax technique, which was introduced by

Taggart in 1907. But certain properties of wax like,

distortion, thermal sensitivity and high coefficient

of thermal expansion can make it a less desirable

option.8

Resins can also be used to overcome the

limitations of conventional wax patterns. Resins can offer strength, rigidity, and dimensional

stability if immediate investment is not possible.

But polymerization shrinkage can be an issue with

the use of resins.

The CAD/CAM manufacturing systems have been

introduced for fabricating prosthesis in order to

overcome the disadvantages of the conventional

casting system. It was introduced for dental

applications over 20 years ago to prepare ceramic

inlays and veneers, and several studies have

presented favourable reports.9

It includes both the

additive technique and the subtractive technique.

There are various techniques to evaluate the

marginal and internal fit of restorations. One

among those is the cross-sectional method. In

this method, the prosthesis is cemented onto the

die and then cut. It is then measured for marginal

and internal gap using an optical or electronic

microscope.10 Various other techniques have been

described in the literature. Some of them are the

direct visualization technique under microscope,

replica technique and weighing technique. Also,

clinical evaluation methods using explorer and

scoring, micro-CT and 3D analysis can be used

for evaluation of the restorations.11

Even though different methods are available to

measure the fit of a restoration, there is no clear

consensus regarding the optimal fit. Therefore, the

purpose of this in vitro study was to evaluate the

influence of the different fabrication techniques

on the marginal and internal fit of restorations.

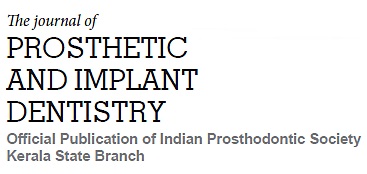

Fabrication of master die:

A stainless-steel die was fabricated using the CNC

(computer numerical control) milling machine (fig

1). This master die was used for the standardized

production of copings. The master die replicated

the form of a prepared premolar tooth. It had a

16-degree total occlusal convergence (TOC), 6mm

height, 5mm diameter and a 360-degree chamfer

finish line.12

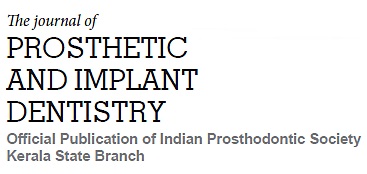

Fabrication of custom-made impression

tray:

For making the impressions of the master die,a

custom-made stainless-steel impression tray

was fabricated (fig 2). The custom tray was in a

hollow cylindrical shape with 2.5cm length and

3cm diameter. One side of the custom tray was

covered with a square shaped stainless-steel

plate. Holes were made on the outer surface of the

cylindrical custom tray and on the stainless-steel

plate. These holes aided in mechanical retention

of the impression material and also provided an

escape way for the excess impression material.

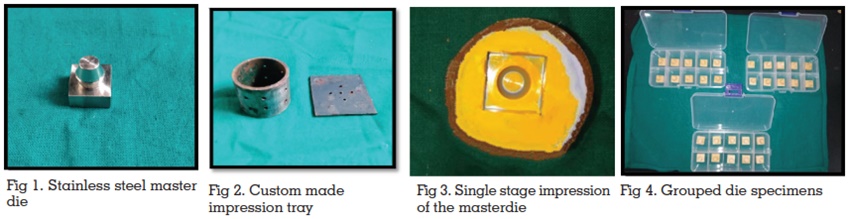

Obtaining the die stone models:

Impressions of the stainless-steel master die were

made with addition silicone impression material

(GC Flexceed, GC India Dental Pvt Ltd, Medak,

India) (fig 3) using single-stage technique. The die was placed on a flat surface and the custom

tray with the loaded material was inverted onto it.

The stainless-steel plate was placed on the upper

side and firm pressure was given from above. A

total of 30 impressions were made. Surfactant was

sprayed into the mold cavity and type IV die stone

was poured using a mechanical vibrator to obtain

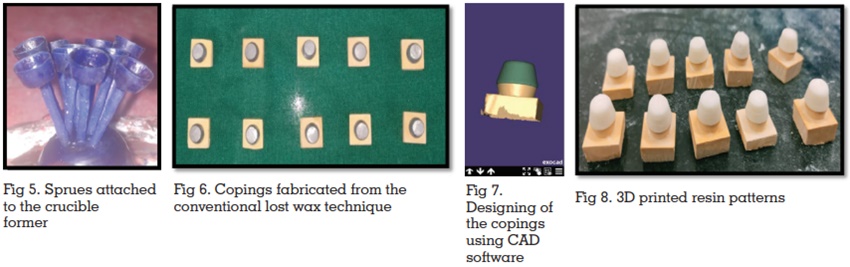

the die stone models. The dies were divided into

three groups of 10 dies each (n=10), i.e., Group 1

(Conventional lost wax group), Group 2 (3D resin

printing group) and Group 3 (CAD/CAM milling

group) (fig 4). Impressions made for Group 1 were

poured twice, because the same die cannot be

used for coping fabrication and cementation as

manual spacer application is needed. In case of

the other two groups, cement space is created

virtually, and the same die can be used for coping

fabrication and cementation.

Fabrication of Co-Cr copings with the

conventional lost wax technique:

One layer of die hardener (Yeti dental products,

Germany) was applied on all of the 10 dies.

Later, 2 layers of die spacers(Yeti dental

products, Germany) were applied 0.5mm below

the preparation. Each layer was about 15µm in

thickness, so totally a 30µm thick spacer was

applied. Each die was dipped into a wax pot

containing molten inlay wax to obtain a wax

pattern of 0.5mm uniform thickness, which was

measured using a wax gauge (API wax gauge

caliper, India). The wax patterns were viewed under a magnification glass to assess for any

discrepancy. Prefabricated sprues of 3mm diameter

were attached to all the patterns(fig 5) and they

were invested using phosphate-bonded investment

material (Metavest,Germany) according to the

manufacturer’s instructions. After 30 minutes,

burnout was done followed by casting with Co-Cr

alloy (Wirobond C, Bego, Germany) in an induction

casting machine (Fornax T, Bego). The investment

was then bench cooled and divested. The copings

were then sandblasted, trimmed and finished.

(fig 6)

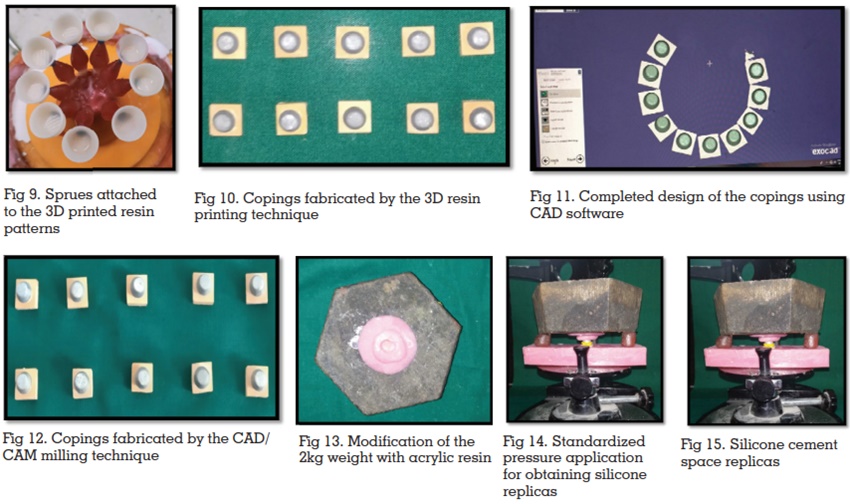

Fabrication of Co-Cr copings using the

3D resin printing technique:

10 master die stone models were scanned using

an extraoral lab scanner (Medit-T, Medit corp,

South Korea). Designing of the copings was done

using a CAD software (Exocad, GmbH, Germany).

(fig 7) The thickness of the copings was set at

0.5mm and an internal relief of 30µm starting from

0.5mm from the margin was given for the luting cement. The CAD data was sent to the 3Dresin

printing system (Anycubic Photon, China). Printing

of the pattern was done using a UDMA (Urethane

dimethacrylate) based castable resin contained

in a cartridge. After the printing was done, the

resin supports were cut using a carborundum disc.

The resin patterns were placed on the respective

models(fig 8) after which the conventional steps

like sprue attachment, (fig 9) investment, burnout,

casting, divestment and finishing were done,(fig

10) similar to the conventional lost was technique.

Fabrication of the Co-Cr copings by the CAD/CAM

milling technique:

10 dies were used to fabricate CAD/CAM milled

Co-Cr copings. The dies were scanned by a 3D

laser scanner (Shining 3D DS-EX). The STL data

obtained was transferred to the CAD software

(Exocad, GmbH, Germany) where the designing of

the copings were done. (fig 11) The design included

an internal relief for the luting cement. 30µm of

internal relief was given starting from 0.5mm from the margin. The thickness of the copings was set

at 0.5mm. The data was sent to the CAD/CAM

milling production unit (Dentium rainbow TM Mill,

Dentium, South Korea), where a 5-axis milling of

a solid Co-Cr disc was done. (fig 12)

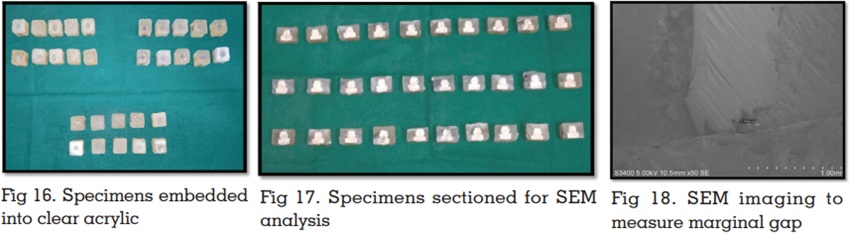

Making a custom-made set up for

cementing the copings:

To standardize the cementing force, a custom

made set up was used. It consisted of a rectangular

acrylic slab and a 2kg weight. A depression was

created on the surface of the acrylic slab where

the base of the die could fit in. A commercially

available 2kg weight was used to apply pressure

on the copings during cementation. The hole on

the under surface of the 2kg weight was filled with

self- cure acrylic resin and a depression was made

(fig 13) which would fit onto the occlusal surface

of the copings.

Volumetric evaluation of the internal fit:

Equal amounts of addition silicone light body base

and catalyst (GC Flexceed, GC India) were mixed

and loaded onto the intaglio surface of the copings

and the copings were seated on their respective

dies. To apply a cementing force, the custom-made

acrylic slab was placed on the surveying table of a

surveyor, the die along with the coping was placed

on the depression in the acrylic slab. The 2kg

weight was placed on the copings, by positioning

the depression exactly on the occlusal surface. For

additional support, two wax pillars were placed on either side of the acrylic slab. The 2kg weight

was stabilized by lowering the vertical arm of

the surveyor such that it contacted the surface of

the 2kg weight (fig 14). This cementing force was

maintained for 2 minutes until the material set.

The excess material was removed with an explorer

and a No.13 bard parker blade. The coping was

removed from the die with a slight twisting and

rocking motion. Each silicone cement space

replica was retrieved carefully. This procedure

was done for all the 30 copings in total. The silicone

cement space replicas were labelled and kept

separately according to their group. (fig 15) Each

cement space replica was weighed in a digital

analytical weighing machine (Sartorius CP225D).

An increased weight of the silicone cement space

replica indicated a greater cement space and a

subsequent decrease in the internal fit.

Cementing and embedding the

samples:

After making the cement space replicas, the

intaglio surface of each coping was cleaned.

The copings were placed on their respective dies

and inspected for any abrupt marginal gap before

cementation. Type I GIC (GC Fuji, Japan) was

used for cementing the copings. Manufacturer’s

recommendations were followed for mixing the

cement. The same customized set up that was used

for making the silicone cement space replicas was

used for cementing the copings onto the dies. The

excess material was removed using an explorer immediately and carefully. Care was taken not to

damage the margins of the die stone models. The

cementing pressure was maintained for 5mins

until the cement was set. After cementation the

specimens were cleaned and embedded into clear

acrylic resin poured into the putty impression of

a cubic box. (fig 16)

Measurement of the marginal gap using

the scanning electron microscope

After embedding, all the specimens were sectioned

using an electronic saw (fig.17). The sectioned

specimens were used to evaluate the marginal

gap discrepancies. Since, the specimens were

non-conductive, they were sputtered with gold-palladium (Au/Pd) using a sputter coater (Quorum,

SC7620, Quorum Tech, United Kingdom) for 4

minutes to make them conductive and to obtain

a good quality image. Analysis of the specimens

to measure the marginal gap was done using a

scanning electron microscope (Hitachi, S-3400N) at

different magnifications of 50- 200x. The distance

between the external edge of the metal coping

and the margin of the die was used to measure

the marginal gap discrepancy. (fig 18) All the 30

specimens were measured for marginal gap.

Statistical Analysis:

Data obtained were compiled systematically

in Microsoft Excel 2010 spreadsheet. Statistical analyses were performed using a personal

computer in IBM corp. Statistical Package for

Social Sciences software for windows; version

20.0 (Armonk, NY). Both descriptive and inferential

statistics were used. P value of < 0.05 was

considered to be significant. One way ANOVA

with Tukey’s post- hoc test was used to compare

the mean difference between the groups.

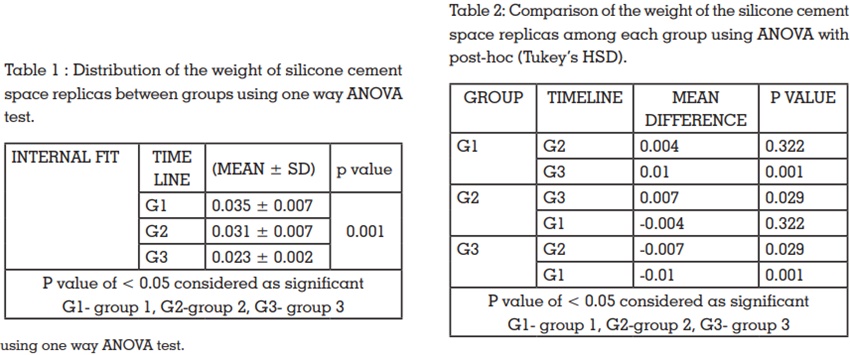

The mean weight of the silicone cement space

replicas for group 1 was 0.035± 0.007 g, for group 2

it was 0.031± 0.007 g and 0.023± 0.002 g for group

3. The mean weights of the silicone cement space

replicas of the three groups were compared using

one-way ANOVA test. A significant difference (P

< 0.05)was seen among the three groups (table

1). The lowest mean weight of the silicone cement

space replicas was seen in group 3, followed by

group 2. Group 1 had the highest values.

Intergroup comparison of the weight of silicone

cement space replicas was made using ANOVA

with post-hoc (Tukey’s HSD). There was no

significant difference when group 1 and group

2 were compared. But there was statistically

significant difference when group 3 was compared

with group 1(P < 0.05)and also with group 2 (table

2)

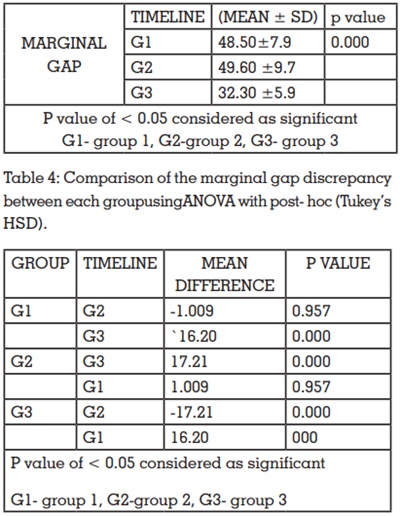

Mean marginal gap forgroup 1 was found to be

48.50 ±7.9µm,49.60 ±9.7 for group 2 and 32.30

±5.9 for group 3. A significant difference (P < 0.05)

was found between the mean marginal gap of the

three groups when they were compared using one-way ANOVA (table 3). Intergroup comparison of the

mean marginal gap between the three groups was

done using ANOVA with post- hoc (Tukey’s HSD).

No significant difference was seen between group

1 and group 2. There was statistically significant

difference (P < 0.05)when group 1 and group 2

were compared with group 3. (table 4)

The chief objective of prosthetic treatment is

to rehabilitate the patient with a well-fitting

restoration. The marginal and internal fit play

an important role in the long-time survival of a restoration.13 The fit of a cast restoration is the most

important factor for it to be clinically acceptable.8,14

For the standardized production of copings, a

custom-made stainless-steel master die was used.

In some previous studies, tooth preparation for

the specimens was done manually which can

lead to incorporation of errors.15,16 Many in vitro

studies have assessed the effect of the margin

configuration on the marginal fit of metal ceramic

restorations. In an in vitro study by Kane et al,

chamfer marginal design for CAD/CAM milled

copings of posterior teeth models showed smaller

marginal gap when compared to the shoulder

margin design6

. Thus, in this study, since a master

model representing a posterior teeth preparation

was used a chamfer margin was opted for the

master model.17

The dimensions of the cement space were also

standardized. Also, alloys containing Nickel have

known to possess more sensitization potential,

thus Co-Cr alloy was used for fabricating the

copings.15,16

The ringless casting technique has shown to

produce copings with improved fit when compared

to metal ring casting. This is because, an equalized

expansion of the refractory mold is achieved by

the ringless casting technique.18 Thus in this study,

the ringless casting technique was followed.

The milling unit that was used in this study to

fabricate CAD/CAM milled copings had a 5-axes

milling function. The increase in the milling axes

facilitates the milling of complex geometries also.3

Vojdani et al have suggested the use of a constant

force of 20N as ideal for cementing the copings8

.

An object of 1kg equals to 9.80665 N of force. In this

study a 2kg weight was used, which corresponds

to 19.6133 N which is closer to 20N. Many studies

in the literature have used finger pressure for

cementing the copings on the dies.7,13,17,19,15,16,20 It

should be noted that though it simulates the clinical

cementation of the copings, since finger pressure

is variable, a standardized pressure cannot be applied on all copings.

Various techniques are available for the

measurement of marginal and internal gaps,

which includes the direct viewing, cross-sectional

technique, silicone replica technique, weighing

the light-body silicone and visual examination.

Nawafleh et al have reported that for measuring

the marginal gaps in CAD/CAM fabricated

restorations, scanning electron microscope

analysis was better than light microscopy.21 Thus,

in this study, the cross-sectional technique with

subsequent scanning electron microscopy analysis

was used to measure the marginal gaps.

The weighing technique used in this study are

similar to that used in the studies by Joo Kim et

al11 and Ucar et al9.

In two separate studies by Al Saady et al22 and

Kocaagaoglu et al23, the marginal fit for CAD/CAM

milled copings was found to be better. The results

of the present study agree with the above studies.

The results of the present study also support the

study by Nesse et al24 in the fact that CAD/CAM

milled copings have better marginal as well as

internal fit.

The results of this study are contrary to the

results obtained by Farjood et al25 in which the

conventional technique was found to be better.

The poor marginal and internal fit of conventionally

cast copings can be attributed to the accumulation

of the manual errors in each step. Also, in the

induction coil heating, due to the increased

temperature some components of the alloy which

have low melting point are lost, making the alloy

more viscous. This can also affect the fit of copings.

According to Bhaskaran et al, vertical marginal

discrepancy of 10-160 µm and internal gap of 81-

136 µm were clinically acceptable. On the other

hand, Moldovan et al13 suggested that marginal

misfit of 100 µm is considered good and 200-300µm is considered as acceptable. McLean and von

Fraunhofer suggested 120 µm of marginal gap as

clinically acceptable27 and the marginal gap of

the copings in this present study were within the

clinically acceptable range. A clear consensus

regarding the marginal and internal fit seems to

be lacking.

It is concluded that the Co-Cr copings fabricated

by the CAD/CAM milling technique had the best

marginal and internal fit, followed by the 3D

resin printed copings and the conventionally cast

copings. Thus, the null hypothesis that there will

not be any statistically significant difference in

the marginal and internal fit among the groups

was rejected. Despite the increased marginal gap

discrepancies in the 3D resin copings and the

conventionally cast copings, the marginal gap

values were within the clinically acceptable range.

Within the limitations of this present study, the

results drawn suggests the use of CAD/CAM milling

technique and the 3D resin printing technique for

fabricating restorations in routine dental practice.

Moreover, future studies with larger sample size

and multiple measuring points are necessary to

further support the adoption of newer techniques

like the CAD/CAM milling and 3D resin printing.