PURPOSE: The aim of this study is to evaluate

and compare the strains generated by short and

conventional implants supporting a distal extension

removable partial overdenture under axial and

oblique loading.

MATERIALS AND METHODS: A mandibular

photoelastic resin model was printed based on

a computed tomography scan of a patient with

bilaterally missing mandibular posterior teeth. Two

implants were placed- short (4.3x6mm) on the right

side and conventional (4.3x10mm) on the left side

second molar region. A conventional Kennedy’s

Class I implant retained RPD was fabricated.

Maximum static loads of 100 N were applied in both

vertical and 45 ooblique directions in the second

molar region of the denture. Ten tests were done for

each group. The stress values around the implants

were derived from the colored fringe patterns that

were photographed after the load applications

from which strain values were derived. Data were

analyzed by unpaired t-test.

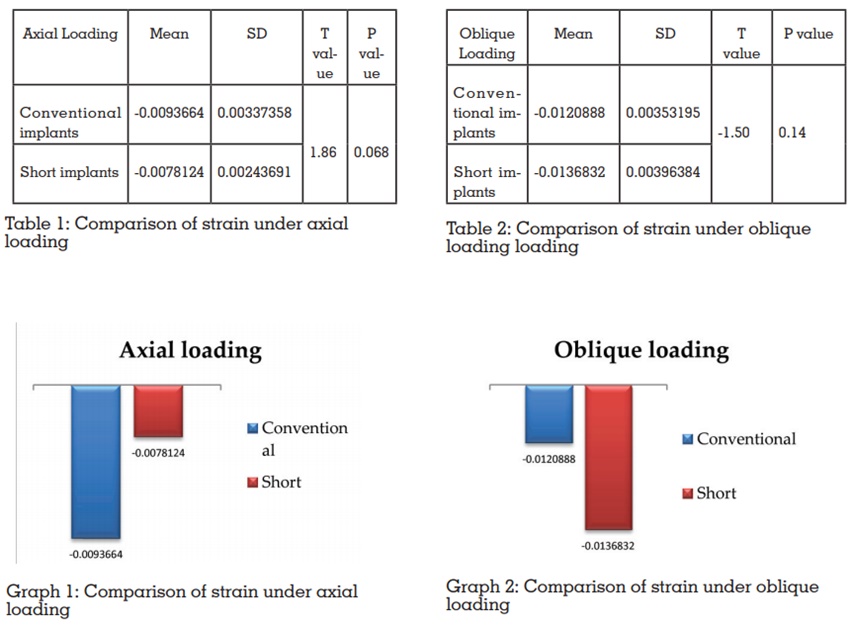

RESULTS: In both conventional and short implants,

the strains around the neck of the implants were

more on oblique loading compared to axial loading.

Comparison of average compressive strain under

axial and oblique loading showed no significant

difference between conventional and short implants.

INTERPRETATION & CONCLUSION: 1) There is no

statistically significant difference between the strains

generated by conventional and short implants under

vertical loading and oblique loading

2) The generated strains were more under oblique

loading compared to axial loading.

Key words: conventional; short; overdenture; strain; photoelasticity

Implants have revolutionized dental practice and

have helped overcome many of the limitations

encountered with conventional fixed or removable

prostheses and is considered as an aesthetic and

functional restoration.

Placing two implant abutments distally in the

mandible has been recommended to transform

a bilateral distal extension (Kennedy’s Class I)

RPD to a tooth and implant-supported/assisted

RPD (a pseudo-Kennedy’s Class III). The pseudo-Kennedy’s Class III design will improve the support,

stability, and retention of a distal extension RPD. This could be seen as a cost-effective alternative

compared to implant-retained fixed prosthetic

options1, 2.

Not all patients have sufficient bone height in

the posterior region and are often disinclined

to submit themselves to invasive surgeries prior

to the placement of the implants. These include

bone-grafting procedures in the region, or even

nerve lateralization of the inferior alveolar nerve,

which may also result in permanent paresthesia3.

An alternative is the use of short implants4,5.

Conventional implants are the preferred option

for any prosthesis. But in compromised situations

usage of short implants can be beneficial compared

to surgical corrections. Investigations on the use of

short implants have led to diverse results, and the choice remains controversial. This in-vitro study

proposed to evaluate and compare the strains

generated by short and conventional implants

supporting distal extension removable partial

overdenture in order to help the clinician make

the right choice and achieve long-term clinical

success6.

A real-life arrangement comprising of a mandibular

model was made using C-51(3222) resin and K-6

hardener employing Fused Deposition Modelling

based on a computed tomographic scan of a

patient with bilaterally missing mandibular

posterior teeth. Soft tissue was duplicated using

Gingifast- Elastic.

One short (4.3x6mm) and one conventional

(4.3x10mm) titanium tapered threaded implants

(JD Evolutions) were placed on the right and left

sides respectively in the second molar region of

the photoelastic model with an osteotomy kit, using

a standard protocol.

A conventional Kennedy’s Class I RPD with a

lingual bar (0.5 mm), mesial rests with canine

extensions (indirect retainers) and I bar was

fabricated with cobalt-chrome-molybdenum alloy

(Wironit® BEGO, Bremer Goldschlägerei Wilh,

Germany). The male component of the locator

attachments was then picked up and secured in

the denture with autopolymerizing acrylic resin.

(Fig 1)

A static load of 100 N was applied in the second

molar region, in both vertical and 45-degree

oblique directions, using a universal testing

machine (EMIC-DL 3000, Universal Test System).

Ten tests were done for each group. During each

load sequence, the isochromatic fringes were

observed and photographed within the field of the

circular polariscope with a digital camera (Canon

EOS 1300D) with a resolution of 5,184 x 3,456

pixels, while the prostheses were under load for

one minute. The changes in colored fringe patterns

on load application were clearly captured. The

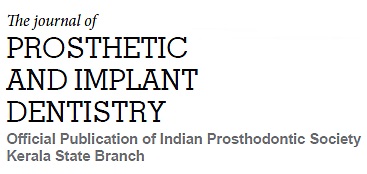

fringe orders were determined by Tardy method

of compensation. 5 points were considered for

determining the strains;Point 1: mesial-cervical,

Point 2: Mid-mesial, Point 3: Apical, Point 4: Mid-distal, and Point 5: Distal-cervical. (Fig 2)

Stresses in the marked points were determined

using the stress-optic law and from these stress

values, amount of strain in a particular region

was determined. Strain distribution data were

generated for both conventional implants and short

implants under both axial and oblique loading.

The collected data were analyzed by unpaired

t-test (student t-test).

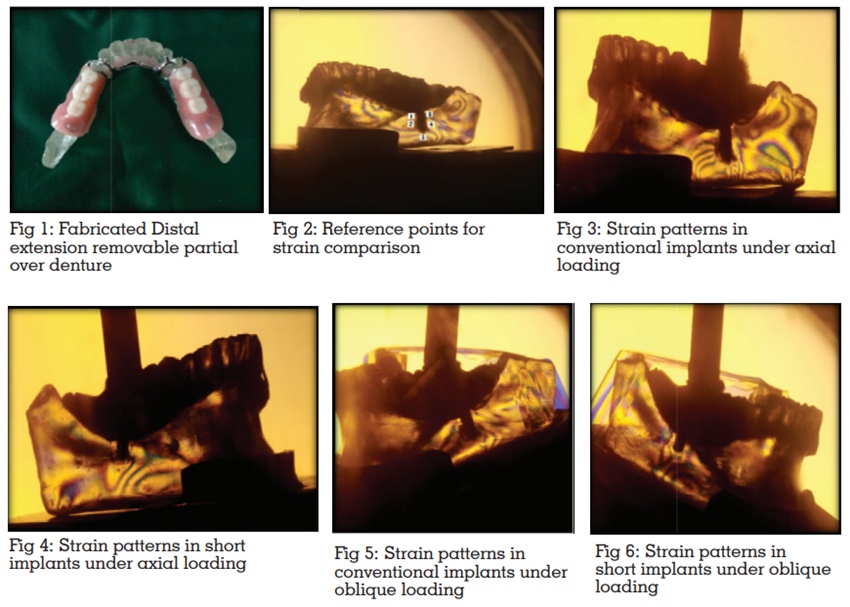

The pattern and distribution of strain were different

under vertical and oblique loading.

The compressive strains generated by conventional

implants under axial loading was more than short

implants but it was not statistically significant

(p=0.068). A marked increase in strain was noted

in the apical region of conventional implants.

Under oblique loading condition, short implant

generated higher strain than conventional implant

but the difference was not statistically significant.

But a significant increase in strain was noted in the

crestal region of the short implant under oblique

loading. (p=0.14)

The strains generated by conventional and short

implants under oblique loading was significantly

higher (p=0.008, 0.001) than that of axial loading.

In both cases, oblique loading showed greater

strain with higher concentration in the crestal

region.

Implants in conjunction with Kennedy’s class I

RPD was used for the first time in the early 1970s,

and since then clinical trials have indicated good

implant survival rates7

. The response of bone

to applied stress has been well documented to

influence the success or failure of an implant8

.

As far as implant shape is concerned, design

parameters that primarily affect load transfer

characteristics (the stress/strain distributions in the bone) include implant diameter and the length

of the bone-implant interface.

Mandibular posterior region is found to undergo

continuous resorption with time. Previous studies

have correlated this resorption with reduced muscle

activity9

. The main factor to be considered is the

difficulty in finding bone height and thickness

in the posterior region of the mandible sufficient

for placing a conventional implant to support a

prosthesis without the need for lateralization of the

mandibular nerve or bone graft3

. The reason can

be attributed to long-standing edentulous ridges.

Short implants in this region are an interesting

alternative and a therapeutical option to vertical

augmentation since the treatment is faster, cheaper,

and associated with less morbidity5

. Recent studies

have shown positive results for short implants even

for those shorter than 7 mm in length10.

Implants were placed in the second molar region

as many investigations have mentioned that the

location of an implant underneath the denture base

is closer to the second molar, better the occlusal

support11,12.

The overdenture was attached to the implants

using locator abutments on both sides. The

locator attachments are an alternative to ball

attachments, especially when the interarch

distance is inadequate to avoid the denture base

deformation and fracture13. The 100N load selected

represents a load relative to a standard bite force

for a patient with an RPD and was a load that the

photoelastic model could repeatedly withstand

without deforming14,15.

A photoelastic analysis was done to evaluate

the strains. Photoelastic models have been used

successfully to indicate the differences between

various prosthetic designs and the effects of

compromised conditions through a comparative

evaluation of stress-related outcomes6

.

There was no statistically significant difference

between conventional and short implants under axial and oblique loading. The results comply

with the previously published work which has

shown that the behavior of conventional implants

is similar to short implants1,5, 7,10,16,17,18,23. However, a

few studies have shown that a reduction in implant

length increased stress values with a significant

difference3,8,19. This difference could be because

most of the studies were done on fixed prosthesis

and characteristics of implants under removable

prosthesis may be variable.

In conventional implants and short implants, the

strains under oblique loading were more compared

to axial loading which was statistically significant.

Many studies have shown that the nonaxial forces

tend to cause uneven strain distribution leading to

areas of higher strains and others of low strains7

.

This coincides with the findings of Barbier et al

(1998) and non-parametric computerized models

of loaded dental implants by Meijer et al (1996)

and Lai et al (1998)7

. Many clinical studies had

agreed that more bone loss has been observed

around dental implants under oblique loads than

those under axial loads20.

Conventional implants showed higher strain in

the apical region under axial loading. (Fig 3) A

study had compared implant supported distal

extension removable prosthesis with different

attachment types and shown that in the vertical

application of 100 N load in resilient-resilient

attachment type, stress was more in the apical

region (21). In short implants, the strains in the

crestal region were slightly higher compared to

apical but it was not significant.(Fig 4) However,

a study done by Marcele et al have shown that

under axial loading short implants increased stress

concentration around the implant especially in the

cervical portion (23)(Table 1, Graph 1)

Both conventional and short implants showed

maximum strain in the crestal region and

least strain in the apical region under oblique

loading.(Fig 5,6) A study had compared the stress

distribution with different implant dimensions in

implant-supported partial overdentures and has shown that higher stresses around the implant neck

may be attributed to the fact that this area is mainly

subjected to non-axial masticatory forces, which act

in an oblique direction as in grinding movements,

in comparison to the chopping movements, which

act in an axial direction7

(Table 2, Graph 2)

A two-dimensional finite element analysis

suggested that the modulus of elasticity of the

cancellous bone play a key role in good stress

distribution. When a load is applied to the

superstructure, the resultant stress transfers to

the bone surrounding the implant. When there is

a small difference in the values of the modulus

of elasticity of both cortical and cancellous bone,

the stress will be distributed evenly. Since a dense

bone has the ability to bear the stress which is

applied to it, while in the case of great difference,

the stress will be concentrated on the cortical

bone22.

This study had a few limitations too. Photoelasticity

requires the use of special light-polarizing

materials that may not be fully representative

of bone in terms of mechanical behavior10. The

implant osseointegration and the physiological

mobility of the abutment teeth were not considered.

This study only looked at one IARPD design and

did not consider the numerous designs that could

be adopted23. Long-term follow-up clinical studies

are also recommended to assess the results found

in the present in vitro study.

The use of dental implants can be definitely

recommended for treating all edentulous area.

Also, alveolar bone is preserved after dental

implants and a high degree of success is achieved

with implants in partly edentulous jaws24.

Within the limitations of this in vitro study, the following conclusions were drawn: