Introduction: A key goal in prosthodontics is obtaining

an accurate impression. Although stock trays provide

mechanical retention, manufacturers recommend

using tray adhesive with both stock and custom

trays. There is limited research on the adhesive

bond strength between tray adhesives and both

auto- and light-polymerizing custom tray materials.

Manufacturers recommend using adhesive and

impression materials from the same brand, and

there is ongoing debate about the ideal drying time

for tray adhesives before impressions.

Aim: The aim of this study was to do a comparative

evaluation to determine the tensile bond strength

and drying time of different tray adhesives on a

particular vinyl poly siloxane impression material

using two different tray materials.

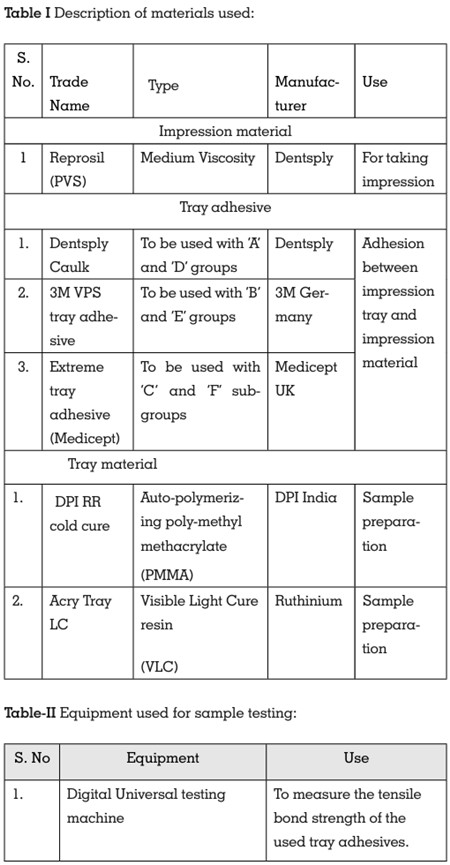

Materials and Methods: A stainless-steel mold

(15×15×20 mm³) was created according to ADA

specification no. 19. A total of 90 samples were

made, including 45 auto-polymerizing and 45 light

polymerizing resin samples, with surfaces polished

using 120-grit sandpaper. An eye hook was attached to each sample, and cylindrical specimens (15 mm

diameter, 20 mm height) were made from PVC to hold

the impression material. Reprosil (medium-bodied) by

Dentsply was used, along with three tray adhesives:

Dentsply Caulk, 3M VPS, and Extreme by Medicept. A

layer of adhesive was applied to the sample surfaces,

dried for three intervals, and tested for tensile bond

strength using a digital universal testing machine

at 5 mm/min until adhesive failure. Data were then

analyzed statistically.

Results: The mean tensile bond strength ranged from

0.168 MPa to 1.058 MPa. The VLC acrylic resin samples

showed significantly higher bond strength than self

cure acrylic samples across all drying times. Dentsply

Caulk performed best with Reprosil VPS, followed

by 3M VPS and Medicept’s Extreme tray adhesive.

Conclusion: Within the study’s limitations, the

manufacturer-recommended adhesive and impression

material combination gave the best results. It is also

concluded that a drying time of 10-15 minutes is

optimal for VPS tray adhesives.

Key words: tensile bond strength, tray adhesives, vinyl poly siloxane, drying time

A primary goal in prosthodontics is to obtain

an accurate impression, which depends on

factors like tray selection, impression material,

technique, and how the material is retained

in the tray. Various impression materials are

available for different clinical situations, and

achieving a precise marginal fit is essential for

the durability of fixed restorations and the health

of surrounding tissues.1,2

Vinyl poly-siloxane (VPS) is one of the most

widely used non aqueous elastomeric impression

materials in dentistry.3 They offer elastic

recovery, dimensional stability, and excellent

detail reproduction.3,4,5 While stock trays provide

mechanical retention for elastomeric impression

materials, manufacturers recommend using

tray adhesive for both stock and custom trays.

After application, the adhesive is allowed to

dry. However, there is limited information on the

compositions of adhesives used with elastomeric

materials.3 The use of adhesives offer more

accurate and consistent impressions.6,7

The required bond strength between elastomeric

impression material and tray to prevent tearing

during removal is unclear. However, clinical

experience suggests that a strong bond is

essential to avoid undetected errors and prevent

ill-fitting restorations.8,9,10 Custom trays are most

commonly fabricated using auto-polymerizing

and visible light cured acrylic resins. The tray

must be rigid to fully capitalize on the physical

characteristics of the impression material.

The recommended adhesives for silicone

impression materials consist of poly(dimethyl

siloxane) and ethyl silicate. Poly(dimethyl

siloxane) adheres to the silicone impression

material, whereas ethyl silicate generates hydrated silica, creating a physical bond with

the tray material. This results in precise and

consistent impressions. There hasn’t been

much focus on attaching impression materials

to trays made of poly methyl methacrylate

(PMMA) or those cured with visible light. The

majority of tray adhesives are produced by the

same manufacturing company as that of the

impression material.

Data on the bond strength between VLC custom

trays, acrylic resin materials, and VPS impression

materials are inconclusive. One study found

higher bond strengths when using different

VPS materials, but lacked statistical analysis.11

An alternative study found that interchanging

the adhesives amongst two addition silicone

impression materials significantly strengthened

the bond between the tray and impression

material. So, it was concluded that the

manufacturer’s

recommended material

adhesive combination may not necessarily be

the best.12

Reported values for the tensile adhesive bond

strengths of vinyl poly-siloxane(VPS) elastomeric

impression materials range from 0.20 to 2.1 MPa,

depending on the tray or impression material

utilized.6,8,9,10

The optimal drying time for tray adhesives is

unclear, with manufacturers recommending 5

to 20 minutes. Some suggest waiting at least

7 minutes, though results are controversial.10

One author concluded that the bond strength

between the tray adhesive & tray material was

highest 48 hours after application.2 According

to results of an another research, bond strength

was unaffected between 15 minutes and 72

hours drying time once it was applied.13 A study

concluded that Impressions should not be taken

before 15 minutes of drying due to insufficient bond strength.14

The aim of the present study was to determine

the tensile-bond strength and appropriate

drying- time of three different tray-adhesives of

different compositions on a single brand of vinyl

poly-siloxane impression material using methyl

methacrylate auto-polymerizing and visible light

polymerizing tray materials.

This in vitro study was carried out in the

Department of Prosthodontics, K.D. Dental

College & Hospital, Mathura in association with

Spectro Analytical Labs Ltd, Ghaziabad (U.P.)

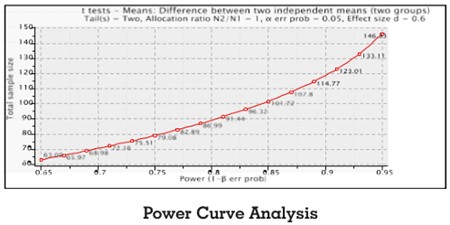

Sample size estimation: The sample size for

the present study has been estimated using

the software GPower v. 3.1.9.7 [Franz Faul,

Universität Kiel, Germany]

Considering the effect size to be measured (d)

at 60% for Two-tailed Hypotheses, power of the

study at 80% and the alpha error at 5%, the

sample size needed is 60. Thus, each group will

comprise of 45 samples. The samples in each

group will be further sub-divided into 3 sub

groups of 15 samples, allocating 5 samples each

for testing the tensile strength at 3 different time

intervals. [5 samples x 3 times interval x 3 Tray

Adhesives x 2 Resins = 90 samples]

The values those were obtained from the

Universal testing machine while doing tensile

bond strength tests, were noted down and used

as data for the results and statistical analysis.

This study was done in the following manner:

Laboratory methods:

Testing of tensile bond strength of the prepared

samples in the UTM.

Fabrication of the stainless-steel die:

A stainless-steel mold was fabricated (15×15×20

mm³) as per the ADA specification no. 19.

The mold creates a window measuring

(15×15×20 mm³) for preparation of the test

samples. (Fig 5)

A plate is provided in the upper chamber to

smooth the test sample’s surface, and a screw

in the lower chamber aids in the easy removal of

the fabricated samples.

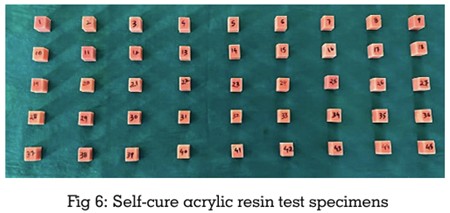

Preparation of the self-cure acrylic resin

test specimens (45 samples)

A thin layer of Vaseline was applied inside the

die to aid in specimen removal. PMMA resin was mixed in a 3:1 polymer-to-monomer ratio and

poured into the die. After polymerization, the

samples were removed by twisting the screw at

the bottom of the die. Excess resin around the

edges was trimmed with an acrylic trimmer,

and the test surface was polished with 120-grit

sandpaper. A small carbide bur was used to

prepare the area for the eye hook, which was

then secured with self-curing acrylic resin. A

total of 45 cube-shaped samples were made

using these steps. (Fig 6)

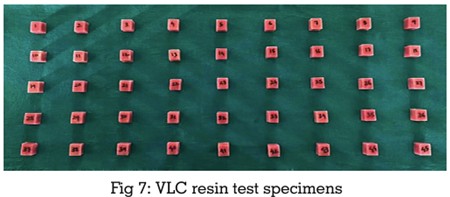

Preparation of VLC resin test specimens

(45 samples)

The VLC resin, in sheet form, was molded to fit

the stainless-steel die. An eye hook was placed

at the center, and the specimen was light-cured

in a UV chamber. After curing, the sample was

removed by rotating the screw at the bottom. A

total of 45 VLC resin samples were prepared

similarly. (Fig 7 & 8))

Preparation of PVC pipe open cylinders

for housing of impression material

Cylindrical specimens (15 mm diameter, 20

mm height) were cut from a PVC pipe to hold

the impression material. Five perforations were

made around each cylinder for better retention.

A metal nail was inserted through two centered

holes at the bottom of each cylinder to attach a

hook, providing a second fastening method for

testing at the UTM. (Fig 9)

45 samples of PMMA were divided into three

groups (A, B and C) of 15 test samples each,

similarly 45 samples of VLC resin were divided

into three groups (D, E and F) of 15 samples

each.

Each group was then further subdivided into

three subgroups for testing at three different

drying time intervals, i.e. at 5 minutes, 10 minutes

and 15 minutes respectively.

Group A subgroups were named as a, b and c

Group B subgroups were named as d, e and f

Group C subgroups were named as g, h and i

Group D subgroups were named as j, k and l

Group E subgroups were named as m, n and o

And Group F subgroups were named as p, q and r

Testing the samples for tensile bond

strength in the Universal testing machine

Under Group ‘A’, a thin layer of Dentsply Caulk

tray adhesive was applied to the ‘a’ subgroup

test samples according to the manufacturer’s

specifications using a small brush. The samples

were permitted to dry for five minutes. Next, a PVC open cylinder was placed in the center of

the acrylic specimen testing surface in a stone

index and stabilized with rubber bands. After

a five minute drying period, Reprosil medium

bodied impression material from Dentsply

was combined on a glass slab using the base

paste and catalyst paste with a stainless steel

spatula. In order to ensure correct filling without

cavities, the material was then poured into the

cylinder from the bottom until surplus emerged

from the vents. As directed by the manufacturer,

the impression substance was allowed to

polymerize. After curing, the stone index was

removed. The assembly was secured in a

universal testing machine by hooks on the tray

and cylinder ends, preparing it for standardized

mechanical testing.

Tensile bond test at cross head speed of 5

mm/min was conducted till failure of adhesive

separation from the test specimen occurs.

In the similar way ‘b’ and ‘c’ subgroups test

specimens were with a thin layer of Dentsply

caulk tray adhesive and were dried for 10 and

15 minutes respectively before loading into the

universal testing machine for the tensile bond

strength tests. (Fig. 10)

Keeping the impression material same for

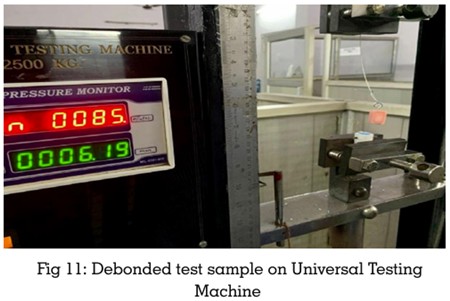

all the groups (i.e. Reprosil medium bodied consistency of Dentsply), group ‘B’ specimens

were coated with 3M VPS tray adhesive and ‘d’,

‘e’ and ‘f’ subgroups test specimens were dried

for prescribed drying time respectively before

loading into the UTM. (Fig. 11) Group ‘C’ Specimens were coated with Extreme

VPS tray adhesive and ‘g’, ‘h’ and ‘i’ subgroups

test specimens were dried for prescribed drying

time respectively before loading into the UTM.

Group ‘C’ Specimens were coated with Extreme

VPS tray adhesive and ‘g’, ‘h’ and ‘i’ subgroups

test specimens were dried for prescribed drying

time respectively before loading into the UTM.

For VLC resin specimens also same

procedures were followed

Group ‘D’ specimens were coated with Dentsply

Caulk tray adhesive and ‘j’, ‘k’ and ‘l’ subgroups

test specimens were dried for prescribed drying

time respectively before loading into the UTM.

Group ‘E’ specimens were coated with 3M VPS

tray adhesive and ‘m’, ‘n’ and ‘o’ subgroups test

specimens were dried for prescribed drying time

respectively before loading into the UTM.

And Group ‘F’ specimens were coated with

Extreme VPS tray adhesive and ‘p’, ‘q’ and

‘r’ subgroups test specimens were dried for

prescribed drying time respectively before

loading into the UTM.

The force was measured in kgF, and the

calculation of tensile bond strength was done

utilizing the formula:

Tensile bond strength = F/A

Here, ‘F’ represents the maximum force causing

separation failure in kgF, A is the area of

adhesion, calculated as the area of the circle

(3.14× r2 in mm², where r denotes the radius of

the circle

i.e., r = [diameter of circle/2], so, r = 15/2 = 7.5

mm

All measurements were recorded in mega

pascals (MPa), and the data underwent analysis.

Statistical Package for Social Sciences [SPSS]

for Windows Version 22.0 released 2013, Armonk,

NY: IBM Corp. was used to perform statistical

analysis of this study.

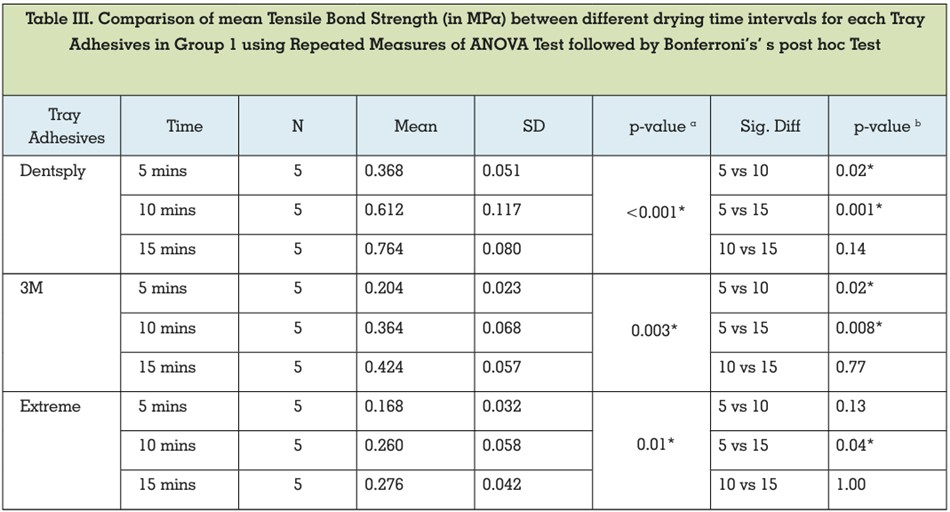

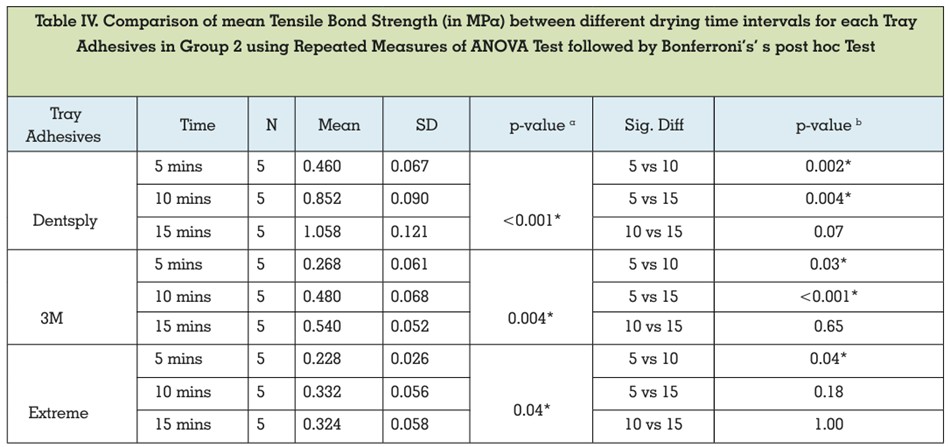

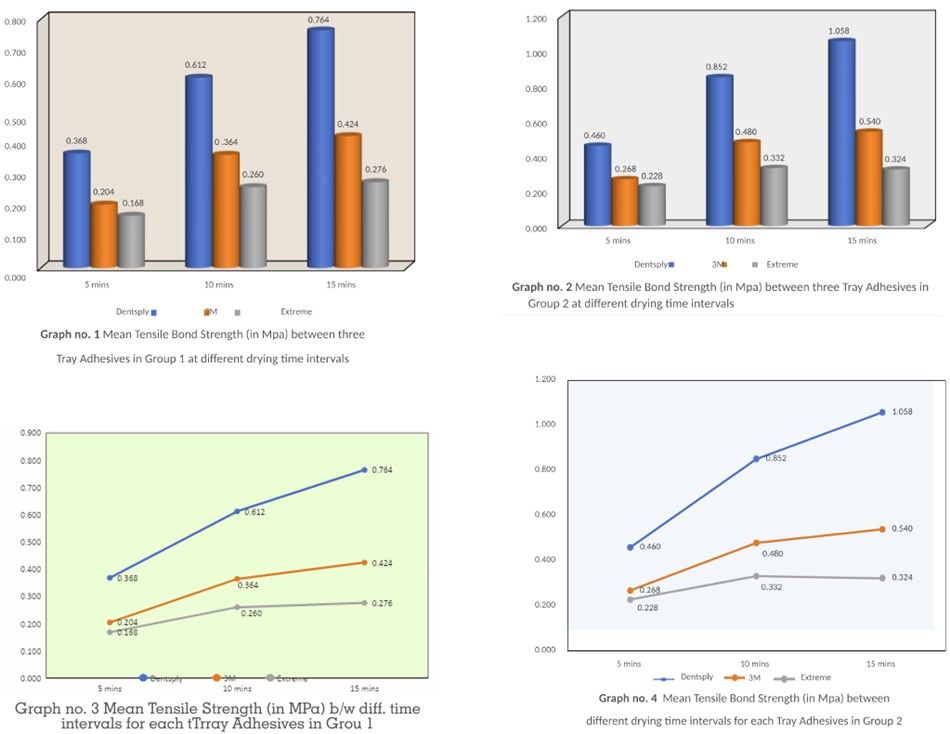

One-way ANOVA test followed by Tukey’s post

hoc test was used to compare the mean tensile

bond strength between tray adhesives in each

acrylic group at different drying time intervals.

Repeated measures of ANOVA followed by

Bonferroni’s post hoc test was used to compare

the mean tensile bond strength between different

drying time intervals for each tray adhesive and

acrylic material.

The level of significance was set at p<0.05 in

this study.

The mean tensile bond strength ranged from

0.168 MPa to 1.058 MPa. The VLC acrylic resin

samples showed significantly higher bond

strength than self-cure acrylic samples across

all drying times. Dentsply Caulk performed best

with Reprosil VPS, followed by 3M VPS and

Medicept’s Extreme tray adhesive. The mean

tensile bond strength significantly increased

with increase in dry time for different tray

adhesives for both the acrylic groups, however,

no significant changes were observed between

10 and 15 minutes drying time intervals.

Vinyl poly-siloxane (VPS) is a commonly used

non-aqueous elastomeric impression material

in dentistry, known for its elastic recovery,

dimensional stability, and detail reproduction.

Stock trays provide mechanical retention,

but manufacturers recommend using tray

adhesive with both stock and custom trays to

strengthen the bond and prevent detachment

during removal. Using adhesives ensures more

accurate and consistent impressions, with the

adhesive applied and allowed to dry before use.

Controversial results are reported regarding to the recommended drying time of tray

adhesive after the application. According to the

manufacturers, the drying time for tray adhesives

ranges from 1 to 20 minutes.

A study concluded that the manufacturer’s

recommended material-adhesive combination

may not always be the best, as there’s no clear

threshold for bond strength between impression

materials and trays. Stronger adhesion reduces

the risk of interface failure, which can affect

the

dimensional accuracy of prostheses.

Dental professionals should select compatible

materials to ensure the strongest bond. Davis et al. found that elastomeric adhesive bonding

was insufficient, requiring significant force to

separate the material in undercuts.13

Depending on tray or impression material used,

the tensile adhesive bond strength ranged

between 0.20 to 2.1 MPa for VPS impression

materials.

In the present study, mean tensile bond strength

values ranged between 0.168 MPa-1.058 MPa.

The tray adhesives used in this study had

different compositions from each other. At 5 and

10 minutes drying time, VLC acrylic samples

showed significantly higher tensile bond strength

than self-cure acrylic samples with Dentsply, 3M,

and Extreme tray adhesives. At 15 minutes, VLC

samples had higher bond strength with Dentsply

and 3M adhesives, but no significant difference

was found with Extreme adhesive.

At the 15-minute drying time, Dentsply adhesive

significantly outperformed 3M and Extreme

adhesives in self-cure acrylic samples (P<0.001),

followed by 3M, which showed higher bond

strength than Extreme. In VLC acrylic samples,

there was a significant difference in tensile bond

strength among the three adhesives (P<0.001).

Dentsply Caulk adhesive showed significantly

higher tensile strength than 3M and Extreme

adhesives (P<0.001). 3M adhesive also had

greater tensile strength than Extreme, with a

significant difference (P=0.004).

Similar results were found in various studies

conducted by different researchers. A. Peregrina

et al. found that mean adhesive values ranged

from 0.13 MPa to 1.09 MPa. Most impression

materials showed higher adhesive strength with

VPS adhesive (GC Universal), except for Take I

material, which showed no significant difference

from GC. Spray-on adhesive resulted in lower

bond strength. No differences were found based on tray material for any of the materials or

adhesives tested.3

B.L. Ashwini et al. compared three VPS impression

materials with auto-polymerizing and VLC trays,

using adhesives from GC America, Zhermack,

and a universal adhesive. Adhesive values

ranged from 0.2 to 1.41 MPa. Polyvinyl siloxane

showed stronger bond strength to VLC trays

than acrylic resin, except with 3M ESPE. The

universal adhesive outperformed manufacturer

recommended adhesives. Dixon et al. found

Triad trays had the highest bond strength

compared to Fastray (PMMA).2

Surender Kumar et al. found a significant

interaction between impression materials and

tray adhesives, with no notable effect from

tray materials on tensile strength (p>0.05).

GC adhesive consistently showed the highest

bond strength, and 3M impression material

exhibited the greatest tensile strength. The best

combination was 3M impression material with

GC adhesive.24

The purpose of John A. Payne et al.’s study was

to evaluate the bonding of two thermoplastic tray

resin materials and two non-aqueous imprint

materials. The combinations of Hydrosil imprint

material and Hydrotray resin (smooth) produced

the highest bond strength, 0.797 MPa, in standard

tensile specimens that were manufactured. The

mean tensile bond strength was measured 0.726

MPa in this investigation.11

The tensile bond strength of the addition

reaction silicone used in the Ben E. Grant et al.

investigation ranged from 0.434 MPa to 0.789

MPa. The majority of failures occurred at the

interface between the adhesive and addition

silicone impression material.6

Myong Hee Yi et al. found that the mean

tensile bond strength ranged from 0.12 to 0.47 MPa, consistent with previous research. The

combination of VPS (3M) adhesive with Imprint

II and Silfix-Aquasil significantly increased

bond strength at 10 and 15 minutes, respectively.

Using adhesives and impression materials from

different manufacturers resulted in lower bond

strength than using a combination from the

same manufacturer.22

George E. Cho and colleagues studied the

time-dependent bond strength of two polyvinyl

siloxane impression materials on acrylic resin

disks, using matching adhesives (p<0.05).

Reprosil’s bond strength started at 16.54 lb,

doubled to 33.96 lb at 15 minutes, and reached

42.11 lb after 15 minutes. After 60 minutes, it

remained steady at 42.11 lb, but dropped to

34.62 lb after 8 hours. The bond strength quickly

increased to 15 minutes and then plateaued.10 It

was determined by G. B. Davis et al. that drying

times shorter than fifteen minutes are clinically

unwise due to their inadequacy in strengthening

bonds. In elastomer bond strength to tray

material, no discernible variation was seen for

drying intervals ranging from 15 minutes to

72 hours.13 Catherine M. Leung et al. studied

the effect of drying time on the cleavage bond

strength of irreversible hydrocolloid adhesive.

The bond strength increased from 32 kPa at 1

minute to 37 kPa at 5 minutes, then decreased.

The study concluded that while adhesive

improves the bond strength to stainless steel,

it should not be left to dry for more than five

minutes.19

Based on these studies, the universal tray

adhesive consistently performed better with

various manufacturers’ addition silicone

impression materials. In this study, Reprosil

(Dentsply) showed significantly higher tensile

bond strength with Dentsply Caulk tray adhesive

compared to 3M and Extreme adhesives, with

manufacturer-supplied combinations yielding

better results than different brand adhesives.

A significant increase in mean tensile bond

strength was noted from 5 to 10 minutes, after

which it plateaued at 15 minutes. Earlier studies

suggest that there is no substantial additional

enhancement in tensile bond strength beyond

the 15-minute drying time. Consequently, the

study results indicate that the optimal drying

time for effective outcomes should be within the

range of 10 to 15 minutes.

Clinical Significance

When removing impressions from undercut

areas, separation from the tray can compromise

accuracy. To enhance adhesion and prevent

detachment, various tray adhesives have been

developed. Universal adhesives typically provide

higher tensile bond strength than manufacturer

recommended ones for VPS materials with

auto-polymerizing and VLC resin trays. Using

adhesives and impression materials from the

same manufacturer often gives better results.

Studies show that bond strength rarely increases

beyond 15 minutes of drying, so a 10-15 minute

drying time is recommended for effective results

with VPS materials.

1) The VLC acrylic resin group test samples had

significantly higher tensile bond strength than

the self-cure acrylic test samples when used

with different adhesives at all the three different

drying time intervals.

2) Overall, in both self-cure and VLC acrylic

resin groups the Dentsply Caulk tray adhesive

showed best results with Reprosil medium bodied

consistency VPS impression material (Dentsply)

in comparison to the other tray adhesives used,

followed by 3M VPS tray adhesive and then the

Extreme VPS tray adhesive at different drying

time intervals.

3) The mean tensile bond strength significantly

increased with increase in dry time for different tray adhesives for both the acrylic groups,

however, no significant changes were observed

between 10 and 15 minutes drying time intervals.

4) As per the results of this study, it can be

concluded that the recommended drying time

should be 10-15 minutes for VPS tray adhesives.