Objective: To provide a new system of spacer

design for the fabrication of complete denture

prosthesis bearing in mind the pattern of residual

alveolar ridge resorption, the stress-bearing, and

relieving areas.

Background: Certain anatomical structures of

the edentulous arches are incapable of bearing

compression and thus, undergo detrimental

changes. Hence, care should be taken to avoid

the application of excessive forces on those

structures. The residual alveolar ridge of maxillary

and mandibular arches have different patterns of

resorption. When areas susceptible to resorption are subjected to unwarranted compression, the rate

of bone resorption accelerates leading to loss of

retention of the prosthesis and diminished support

available for the future prosthesis. Thus, it would

be prudent to design spacers keeping in mind the

resorption pattern of the edentulous arches.

Conclusion: The spacer designs presented in this

article are likely to provide better stress distribution

by displacing the stress-bearing structures and

preventing the resorption of vulnerable areas

by relieving such areas. The new design of the

spacer advocated could limit some amount of bone

resorption, if not, completely prevent it.

Key words: Tissue stops, spacer wax, complete dentures, final impression.

Edentulism is declining at a rate of approximately

1% per year but this is offset by the increasing

life expectancy. Thus, the number of edentulous

patients fairly remains the same or is increasing

slightly.1-2 Rehabilitation with complete denture

prosthesis is a time-tested treatment modality that

serves both the functional and aesthetic needs

of an edentulous patient. They are a great tool

when fabricated accurately, and meticulously

following the proper guidelines. At the same

time, any errors can lead to problems with the

outcome and long-term functionality of the

dentures. Every step in the fabrication of complete

dentures must be given equal attention. One of

the cardinal steps in complete denture fabrication

is impression-making. The objectives behind

making an impression are to provide support,

stability, resistance to dislodgment, aesthetics

for the complete dentures, and to preserve the

underlying anatomical structures.3

The accuracy

of impression-making is paramount in keeping

harmony with the underlying soft and hard tissues

of the denture-bearing area.

Many theories have been put forward by different

schools of thought for recording denture-bearing

tissues. The most significant of them are the

mucocompressive technique described by the

Greene brothers (1900),3-4 mucostatic technique

by Harry L. Page (1944)5

, and the selective

pressure technique by Carl O. Boucher (1951).

According to mucocompressive theory, the entire

denture-bearing area is recorded in function.

The advocates of this technique believed that

the chances of the prosthesis getting dislodged

while carrying out routine functions were very

minimal, but it leads to the placement of additional

pressure on the entire denture-bearing area and

increased chances of residual ridge resorption.

On the other hand, the mucostatic impression

technique deals with making an impression

of displaceable tissue in its passive state, and

interfacial surface tension was considered as one of the main factors that provided retention

for the prosthesis.4

Carl O. Boucher suggested

applying pressure over stress-bearing areas and

relieving the relief areas, creating equilibrium

between the resilient and non-resilient tissues.

Thus, the selective pressure technique is one of the

commonly followed techniques for making final

impressions.6

The selective pressure is provided

by relieving the relief areas using a spacer under

the custom tray.

The custom tray is an individualized impression

tray made from a cast recovered from the

preliminary impressions. A custom tray should

be able to carry the impression material to the

mouth, and control and confine the material to

enable it to record accurately the minute details

of the denture-bearing area.7

Custom trays are

usually fabricated using autopolymerizing acrylic

resins, thermoplastic resins, visible light-cured

resins, or with thermoplastic shellac baseplates.

Space can be created in the custom tray for

providing relief by adapting spacers of different

thicknesses. Various materials employed as spacers

include baseplate wax, casting wax, thermoplastic

sheets, tin foil, etc.8

The most commonly employed

is a baseplate wax used as a spacer under an

autopolymerizing resin custom tray. The objectives

of employing a spacer include providing relief for

the relieving areas and ensuring uniform space for

the final or wash impression material. The main

motive behind providing relief is to ensure that

the areas which cannot withstand forces do not

get compressed in function. When the forces of

mastication continually compress the vulnerable

structures it leads to unwanted changes in the

tissues like resorption of the underlying residual

alveolar bone.

Residual alveolar ridge resorption is a continuous

and progressive process after the extraction of

teeth. The literature suggests different rates and

patterns of ridge resorption for both the maxilla and

the mandible. The pattern of ridge resorption has

to be kept in mind before designing a spacer as the force distribution can be varied and controlled

with the use of a suitable spacer.

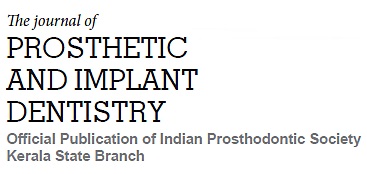

The maxillary edentulous arch: It resorbs upwards

and inwards with progressive narrowing of the

arch due to bone loss that follows the direction and

inclination of the roots of the teeth. The incisive

papilla remains constant as it is little affected by

ridge resorption.9-10

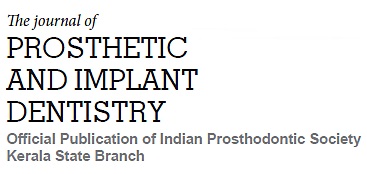

The mandibular arch: There is a bit of controversy

when it comes to the mandibular ridge resorption

pattern. According to one school of thought,

the mandibular ridge resorbs downwards and

forwards. Thus, the alveolar ridge inclines outwards

and the mandible becomes progressively wider.9-10

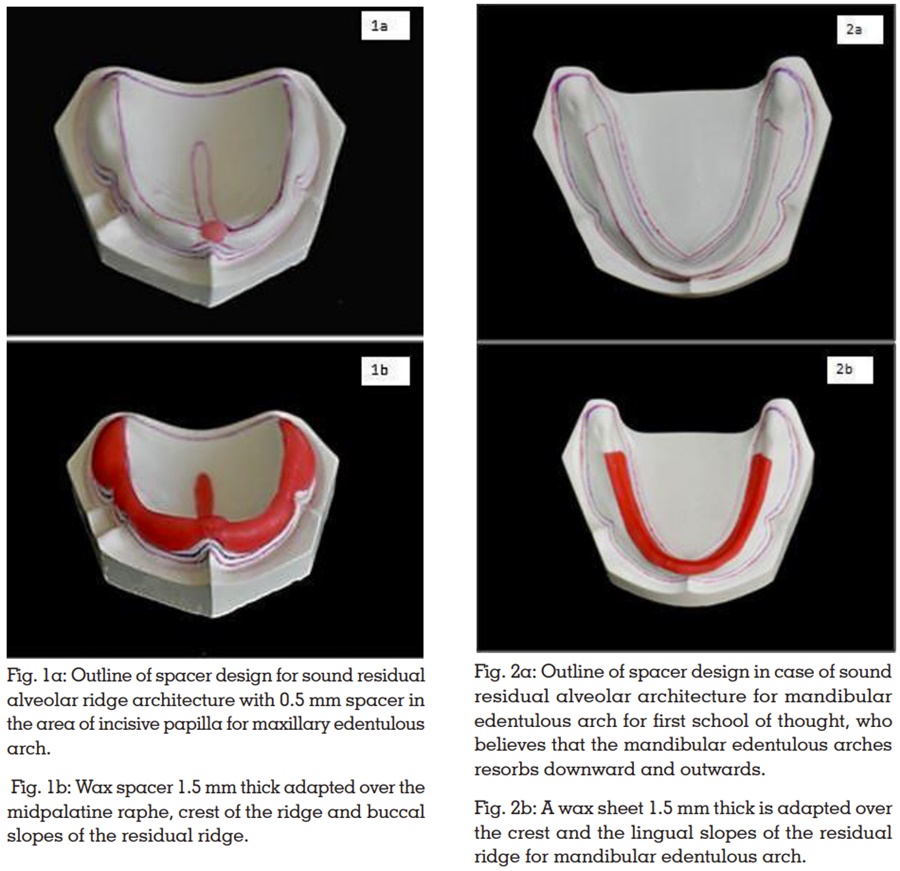

Whilst, the other school of thought suggests that the

mandibular arch like the maxillary arch resorbs

to shrink downwards and backwards.11-12

The present article aims to present a scientific way

of designing spacers for completely edentulous

arches keeping in mind the pattern of residual

alveolar ridge resorption so that long-term success

can be achieved by preserving the existing alveolar

bone for the conventional complete denture

prosthesis.

Various authors have recommended several ways

and methods for designing spacers and providing

relief during final impression-making. A few

noteworthy of them have been briefly mentioned

here.

1. Spacer design by Boucher CO (1951):6,10

Baseplate wax of approximately 1mm thick for

the outlined border is used to provide relief for the

custom tray that is employed for making the final

impressions. For the maxillary edentulous arch,

the whole of the impression surface is covered

excluding the posterior palatal seal area. The

posterior palatal seal area is excluded to provide

additional stress in this area to achieve a posterior border seal. The author suggests that it also acts

as a guiding stop to help position the impression

tray. In the mandibular arch, wax covers the crest

and slopes of the residual ridge. The borders and

buccal shelf areas on either side are left uncovered,

to apply pressure on the primary stress-bearing

areas. Extra wax can be placed in the region

below the mylohyoid ridge to make space for the

action of the mylohyoid muscle. The author does

not recommend a wax spacer if a metallic oxide

impression paste is selected for making the final

impressions.

2. Concept of relief by Winkler S:13

Selective relief is accomplished for the custom

tray depending on the clinical needs presented

by the particular patient. The usual areas of relief

recommended by the author are the incisive

papilla, the rugae zone, and the midpalatine areas.

A small hole, no more than 1mm in diameter, is

placed in the midpoint of the tray for control of

hydrostatic pressure built up in the tray during the

final wash. He has left the choice of placement of

other escape holes at the discretion of the operator

to control wash impression pressures.

3. Design of spacer by Morrow RM et al.:8

The authors advocate first blocking out the

undercuts, followed by the application of one

layer of baseplate wax over the cast and trimming

it to the previously drawn outline 2mm short of

the resin tray border. Three tissue stops are made

by removing 4mm squares of wax to expose the

cast. The exact location of tissue stops can vary.

The authors think that the size and position of the

tissue stops may vary according to the dentist’s

requirements and sometimes the tissue stops may

or may not be required.

4. Design recommendations by Mac Gregor AR:14

He recommends the placement of a sheet of metal

foil in the region of the incisive papilla and mid-palatine raphe. The author also feels that some

areas that may require relief are maxillary rugae, areas of mucosal damage, and the buccal surface

of prominent tuberosities.

5. Design of spacer by Neill DJ and Narin RI:15

He advocated the placement of a sheet of 0.9mm

casting wax over the outlined area of the cast that

will provide a space between the cast and the

impression tray.

6. Concept of spacer design by Rahn AO and

Heartwell CM:16

Two methods have been advocated by Heartwell-the first method includes providing space and relief

in the prosthesis by scraping off the impression

compound in the area to be relieved. The second

method provides 5 relief holes by placing three

holes along the rugae and two holes in the posterior

glandular region.

7. Spacer design by Sharry JJ:17

The author recommends adapting a layer of base

plate wax over the whole area outlined for the tray

including the posterior palatal seal area. Four

tissue stops, 2mm in width located in the molar

and cuspid region that extends from the palatal

aspect of the ridge to the mucobuccal fold are

given. A relief hole is given in the incisive papilla

region.

8. Design of spacers by Bernard L:18

He advocates placing a layer of 2mm thick

baseplate wax in the area of the casts that usually

have softer tissues as this avoids the displacement

of soft tissues covering the palate and the residual

ridges.

9. Concept of spacer by Halperin G and Rogoff

P:19

They recommended the ‘Philosophy of custom

impression tray with peripheral relief ‘. This is

achieved by placing 1mm of wax on the borders

of the custom tray to provide space for the green

stick compound to form a butt joint with the custom

tray and record the borders accurately.

10. Spacer design by Shetty S et al. (2007):20

According to them, a sheet of 0.4mm thick wax is

adapted over the entire maxillary cast except in

the region of PPS. Over this, a 1.5mm thick layer

of modeling wax is adapted avoiding the crest

of the ridge and the palatal shelves, as the crest

and the palatal shelves are stress-bearing areas.

11. Use of Polyvinyl thermoplastic sheet as

spacer:21

Kaur H et al. (2016) used a polyvinyl sheet that

was vacuum-formed over the cast for providing

space and then the stoppers were provided by

trimming into it. The authors thought that this

method overcomes the variability in the thickness

of the spacer in different regions created while

manipulating the wax.

Maintenance of the orofacial region is essential

and will influence the appearance, function,

communication skills, and interpersonal relations

and has an impact on socialization, thereby

enhancing the quality of life.22 The harmony

of the dentures with the orofacial tissues is of

paramount importance in long-term success.

Hence, maintenance of the existing residual

alveolar ridge is one of the main criteria to be

considered while fabricating a complete denture prosthesis.

To uphold the principles of the selective pressure

impression technique it is very important to provide

proper relief to the reliving structures and at the

same time displace tissues that can withstand

forces without causing any undesirable changes.

There are plenty of spacer designs recommended

in the literature and there are a lot of variations

in the concepts and designs. The earlier designs

have not considered the pattern of ridge resorption

to prescribe the design of the spacer.

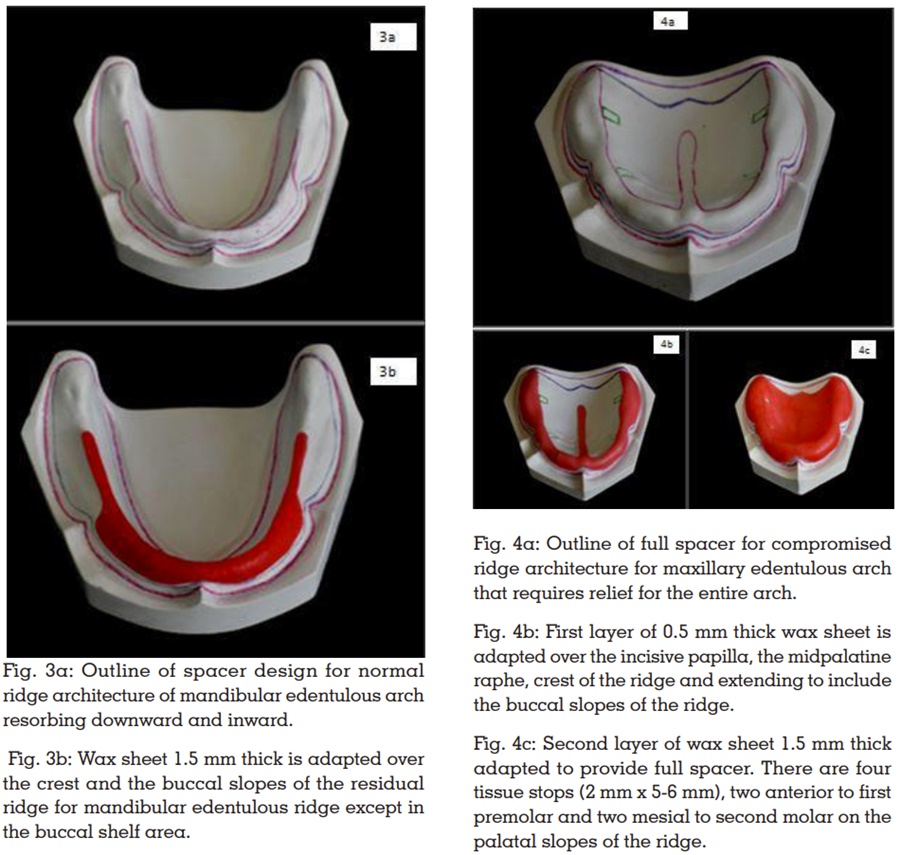

The basis for the formulation of the present spacer

design is the pattern of alveolar ridge resorption.

Hence, all the schools of thought related to the

same are incorporated and in turn, it complies

with DeVan’s concept.23 The spacer designs are

delineated based on different ridge conditions

encountered by the clinicians on a day-to-day

basis. The stoppers are placed in such a manner

that it assists the process of impression-making

as well as does not impinge on relief areas. In

addition, relief holes are provided to help the

excess material escape and there is no excess

pressure built up.24

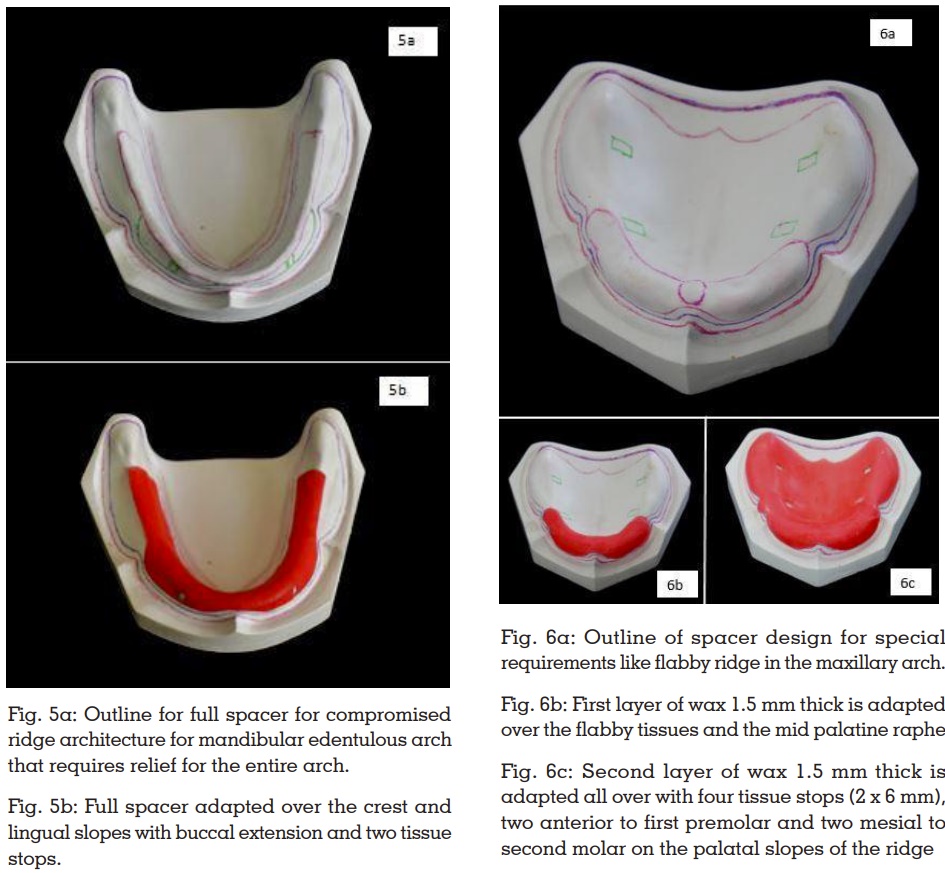

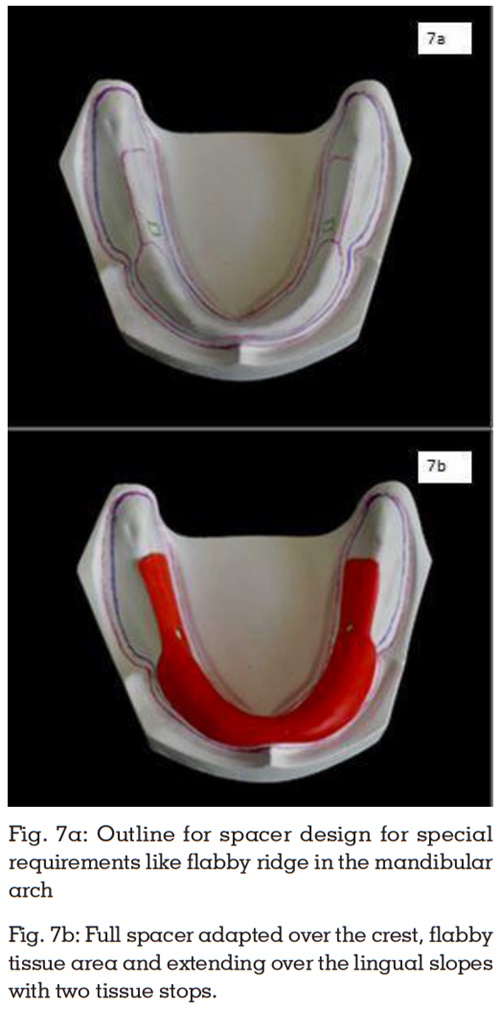

In flabby ridge cases, the most commonly employed

technique is the use of a custom tray with a window

to avoid displacement of the tissue while recording

the same.25 The main concern in cases of flabby

ridges is the provision of enough space, which

is addressed by providing a spacer of 3mm.

The article intends to cover most of the clinically

encountered situations. Any other situation other

than those mentioned can be addressed by

the clinician by applying the same principles

described.

The importance of a good impression cannot be

stressed enough in making a dental prosthesis,

especially in complete denture fabrication where

the entire support and stability are provided by

the underlying tissues. The spacer design helps not just in recording the areas accurately but also

in the preservation of the underlying structures.

A new spacer design is suggested here keeping

in mind the pattern of alveolar ridge resorption.

This novel approach should address the frequently

encountered problems of ridge resorption to some

extent if not completely curb it.