Abstract:

The restoration of edentulism through cast partial

denture is one of the important goals of prosthodontics. The caries destruction of an abutment tooth

supporting a Cast Partial Denture (CPD) is commonly

associated with the loss of retention of the prosthesis,

making it non-functional. Even though the literature

discusses many techniques for the prosthodontic

restoration of destructed abutment tooth supporting a CPD, none of them explains a simple method

which incorporates the retentive features as well as

aesthetics on the definitive restoration. This article

discusses an innovative yet simple technique for

the fabrication of a provisional crown as well as a

definitive porcelain fused to metal restoration, which

can maintain the aesthetics and retentive features

of the abutment. This technique enables the patient

to continue wearing the existing prosthesis.

Key words: Cast partial denture abutment, Rest

seat restoration, Direct retainer, Cast partial

denture retention.

Introduction

The necessity to restore a Cast Partial denture(CPD)

abutment arise frequently when it loses its retentive

property. This can be mainly due to dental caries,

cusp fracture or due to the destruction of its retentive form1

. The absence of the prosthesis may affect

the functional as well as the psychological wellbeing of the patient2,3. In this scenario, the challenge is to recreate the retentive features of crown

in accordance with clasps and minor connector of

an existing partial denture without compromising

aesthetics. Aesthetics of the restoration has an

important role in the psychological acceptance

of the prosthesis by the patient4,5. The literature is

abundant on the retrofitting of a crown under an

existing CPD clasp assembly6-20. This includes the

use of technique sensitive methods like direct wax

up to expensive options like CAD-CAM technology. But none of these articles report a technique

to fabricate a crown which can reproduce the

retentive elements of the original abutment tooth

as well as the aesthetics. In this article a simple and innovative technique to restore an abutment

tooth, maintaining the morphology and aesthetics, with the preservation of the retentive elements

of the existing cast partial denture is discussed.

Technique

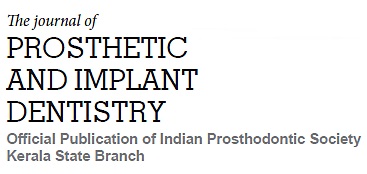

For demonstration purpose, a dental education

model (PE-PRO002, Nissin dental products, Japan)

comprising of a cast partial denture with abutment

having rest and circumferential clasp on a metal

crown on maxillary left first molar was selected.

The existing metal crown in relation to maxillary

left first molar from the model was removed to

simulate a clinical situation of tooth preparation

done to receive a crown under an existing CPD.

- The existing prosthesis was kept over the prepared tooth to ensure adequate clearance between

the prepared tooth and the prosthesis.

(Figure 1. Adequate clearance ensured between

the prepared tooth and rest seat.)

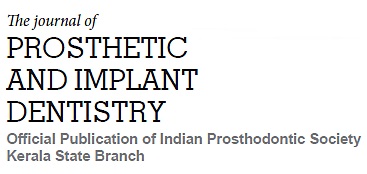

- Petroleum jelly (Bioline, Biopharm, Bangalore)

was applied over the prepared tooth and surroundings. Tooth coloured auto polymerizing resin (DPI-RR Cold cure, Mumbai) was mixed and adapted

over the prepared tooth, followed by the placement

of existing prosthesis. It was made sure that the

indentation of the occlusal rest and circumferential

clasp on the prosthesis was registered on acrylic.

- The acrylic was then moulded in the shape of the desired tooth morphology with the help of

hand instruments.

(Figure 2. Acrylic resin moulded in the shape of

the desired tooth morphology with the help of

hand instrument.).

- The finished acrylic crown was checked for fit

on the tooth and then the cast partial denture was

seated in position.

- A pick up impression of the region was made

along with the temporary crown and the cast partial denture

- Once the cast was poured, a putty index was

made.

- A second temporary crown was made by duplication and this duplicated crown was cemented

for temporization.

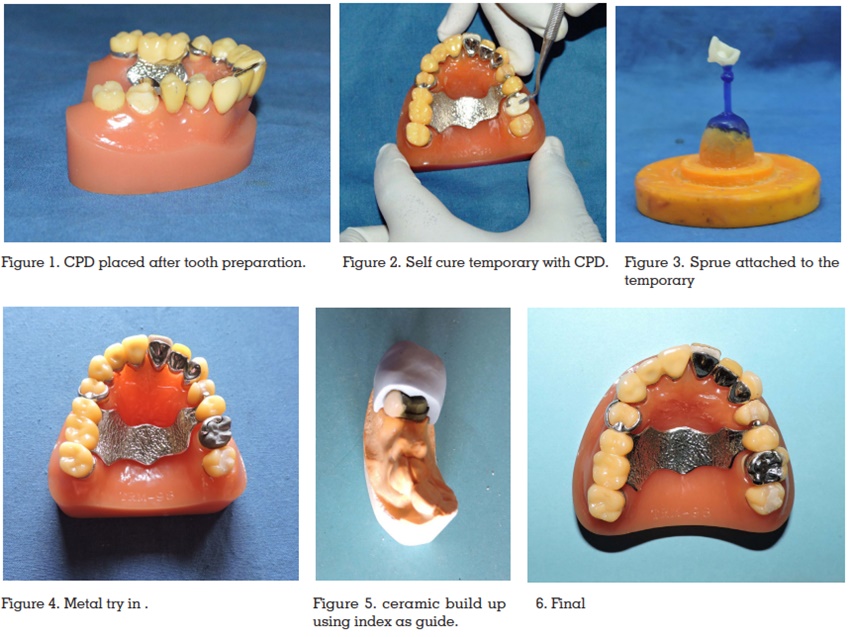

- Cut back was done on the acrylic temporary

crown made by direct method to create space for

the ceramic.

- This acrylic crown prepared by direct method

was thensprued (Renfert, Germany)invested and

was kept in the burn out furnace at 700°C to eliminate the acrylic part and casting was done7.

(Figure 3. Sprue attached to the temporary)

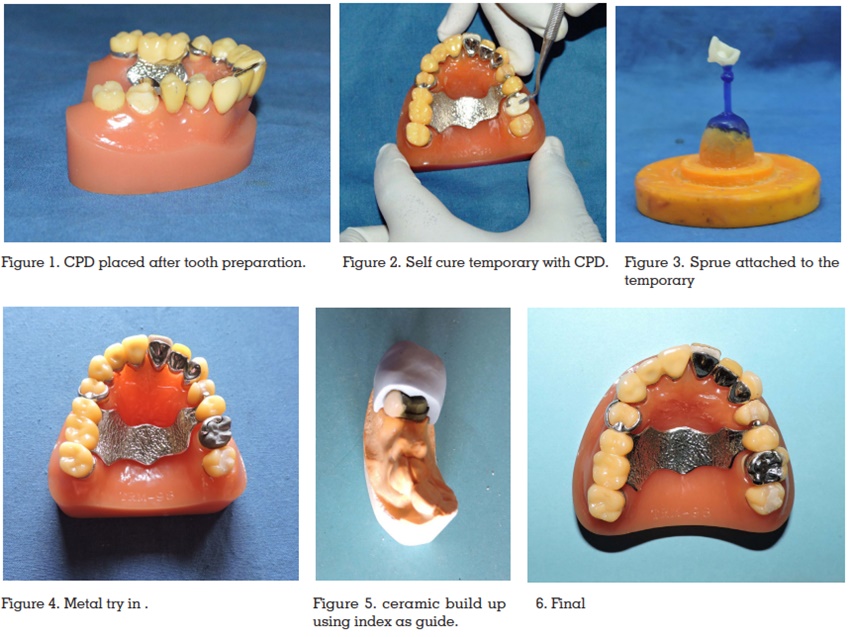

- The casting was divested, finished, and checked

for accuracy on the working cast

(Figure 4. Metal try in).

- Ceramic was added on the labial aspect using the putty index made earlier as a guide and

firing was done.

(Figure 5 Ceramic build-up using the putty index

as the guide).

- After the bisque try in, the definitive prosthesis was glazed and cemented with type I Glass

Ionomer cement.

(Figure 6 Definitive prosthesis.)

Discussion

The discontinuation of the use of existing removable prosthesis can affect the patient’s quality of

life2,3,21. The financial, functional and psychological

well-being of the patient can be safe guarded, if

the existing prosthesis can be made functional

again. This situation demands the retrofitting

of the crown without compromising the retentive

features of the original abutment.

Aesthetics plays an important role in the success of a prosthesis. A prosthesis that is highly

aesthetic will improve patient’s motivation and

acceptance4,5. Ample literature is available on the

fabrication of metal crowns, but the information

available on the fabrication of aesthetic crowns are

very limited or scarce19. Therefore, this technique

will be a valuable addition to literature base and

can be of interest to clinicians working in dental

rehabilitation.

Even though pattern resin is the material of choice,

autopolymerising resin was used as pattern for fabrication of a metal substructure. This is because,the

dimensional stability of the resin in comparison

with the other materials used for the pattern preparation is within the acceptable clinical limits22 - 24.

The percentage of solid residue left after burning

out of thermoplastic resin or cold cure resin during the burn out process was not reported to be

clinically significant23,24. These properties enable

the use of cold cure resin as a pattern material.

The technique described here saves considerable

time and financial burden to the patient. The contour of the crown can be maintained reasonably

without challenging the aesthetics and function

of the partial denture.

Summary

A direct technique for making metal ceramic crown for teeth which carry partial denture rest and clasps

has been described. This is a simple technique

which uses autopolymerising resin as a pattern

to fabricate a crown, supporting a CPD with the

incorporation of retentive features of the existing

denture. The laboratory procedures are described

in detail to be replicated in clinical practice.

REFERENCES

- K W Teppo, F W SmithA technique for restoring

abutments for removable partial dentures.J Prosthet

Dent.1978;40:398-401.

- Koshino H, Hirai T, Ishijima T, Tsukagoshi H, Ishigami

T, Tanaka Y. Quality of life and masticatory function in

denture wearers J Oral Rehabil.2006;33:323-9.

- Chigurupati R1,Aloor N, Salas R, Schmidt BL.Quality of life

after maxillectomy and prosthetic obturatorrehabilitation.J

Oral Maxillofac Surg. 2013;71:1471-8.

- Turagam N, Mudrakola DP, Yelamanchi RS, Deepthi M,

Natarajan M. Esthetic Clasp Cast Partial Denture. J Int

Soc Prev Community Dent. 2019;9:94-98.

- Donovan TE, Derbabian K, Kaneko L, Wright R.

Esthetic considerations in removable prosthodontics.

J EsthetRestor Dent. 2001;13:241-53.

- J E Ewing. The construction of accurate full crown

restorations for an existing clasp by using a direct metal

pattern technique. JProsthet Dent. Sep-Oct 1965;15:889-

99.

- Goldberg AT, Jones RD. Constructing cast crowns to fit

existing removable partial denture clasps. JProsthet

Dent. 1976;36:382-6.

- G M Hill Construction of a crown to fit a removable

partial denture clasp. JProsthet Dent 1977;38:226-8.

- Loft GH, Reynolds JM, Lundquist DO. An indirect-direct

method of crown fabrication for existing removable

partial denture clasps. J Prosthet Dent 1977;38:589-91.

- Ludovico RP, Peterson T. The fabrication of a ceramic�metal crown to fit an existing removable partial denture

clasp. J Prosthet Dent 1977;37:610-4.

- R H Killebrew. Crown construction for Broken down partial

denture abutments,J Prosthet Dent 1961;jan:93-94. Raskin

ER. An indirect technique for fabricating a crown under

an existing clasp. J Prosthet Dent 1983;50:580-1.

- S R Gordon. Making a provisional crown under a clasp

of an existing removable partial denture. J Prosthet Dent.

1992;68:556-7.

- D M Silberman. indirect procedure for making a

crown under an existing partial denture.J Prosthet Dent

1993;69:631-3.

- C A Hansen, M. M. Russell. Making a crown to fit

accurately under an existing removable partial denture

clasp assembly. J Prosthet Dent. 1994;71:206-8.

- G J Livaditis. Fabricating abutment crowns for existing

removable partial dentures using custom resin clasp

analogs.J Prosthet Dent 1998;80:619-29.

- G A Helvey. Crowns to an existing removable partial

denture clasp: A simple technique. J Prosthet Dent

2002;87:399-402.

- M Fujisawa. A procedure for fitting a fixed partial denture

to an existing removable partial denture. J Prosthet Dent.

2004;91:392-4.

- H Lee, A Shirakura. A technique to fabricate a cast metal

crown for an existing removable partial denture using

an acrylic resin template. J Prosthet Dent 2007; 97:181-2.

- Marchack BW, Chen LB, Marchack CB, Futatsuki Y.

Fabrication of an all-ceramic abutment crown under

an existing removable partial denture using CAD/CAM

technology. J Prosthet Dent 2007; 98:478-82.

- Lee JH. Fabricating a crown under an existing removable

partial denture with impression scanning and CAD-CAM

technology. J Prosthet Dent. 2020;124:148-152.

- Breeze J, Rennie A, Morrison A, Dawson D, Tipper J,

Rehman K, Grew N, Snee D, PigadasN.Health-related

quality of life after maxillectomy: obturator rehabilitation

compared with flap reconstruction. Br J Oral Maxillofac

Surg. 2016 ;54:857-862.

- Iglesias A, Pierpont H P, Powers J M Accuracy of Wax,

Autopolymerized, and Light-Polymerized Resin Pattern

Materials, J Prosthodont; 1996;5: 201-205.

- Shillingburg H T, Fundamentals of fixed prosthodontics,

third edition, quintessence publication, New Delhi, 1997.

204-6.

- Hameed N A S, Evaluation of Thermoplastic Resin as a

New Pattern Material for Posts: Dimensional Accuracy

and Detail Reproduction. J Dent Health Oral DisordTher

2014; 1:10-13.

Acknowledgement

The authors would like to thank the guidance and

encouragement of Dr K. Chandrasekharan Nair,

Former professor emeritus, Vishnu Dental College,

Andra Pradesh, India and the Faculty and staff

of Department of Prosthodontics, Amrita School

of Dentistry, Cochin, India