Dentistry today, focuses not only on the prevention and treatment of disease but also on meeting the demands for better esthetics. Therefore, it has evolved from a creative to creative science in a short span. Due to the increase in importance and attention towards esthetics, the demand for metal free prosthesis is on a verge of increase. This article will review all the materials on the progress in dental materials owing to increase in demand for aesthetic.

Key words: Metal- free, esthetics, advances.

The field of dentistry is known for meeting the

requirements of patients by offering dental

restorations and prosthesis such as inlays,

onlays, crowns, fixed partial dentures (FPDs), and

removable dentures, to meet patients’ needs and

maintain their health. During the 20th century, both

dental materials and dental devices progressed

remarkably.1

Owing to the increased demand for

safe and esthetically pleasing dental materials,

new high strength Metal free materials have been

recently introduced.

Biomaterials for dental use are classified into

metal, ceramics, synthetic polymer and composite

materials. For dental prosthesis, previous ceramics

and resin were brittle, and the use of these alone

for restoration and dental prosthesis preparation

was limited due to the problem of the materials

strength. Thus, metal has been frequently used;

prioritizing mechanical strength over esthetics, but

demands for metal-free restoration has recently

increased due to esthetic problems of metal colour

penetration through the marginal gingiva and

gingival staining by metal, a problem of metal

allergy, and environmental protection concerning

rare metals.2

This review outlines the developments and progress

in dental materials over the past decade which

has lead to the evolution of metal free prosthesis

in complete dentures, fixed partial dentures,

removable partial dentures, implantology and

maxillofacial prosthesis.

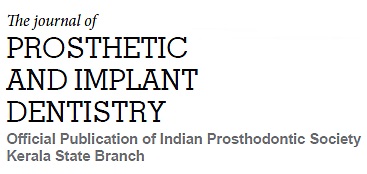

In ancient time metal denture bases were used

but these dentures have heavy weight and

esthetically poor appearance that’s why a newer

material called PMMA (Polymethyl methacrylate) used for fabrication of denture. The mechanical

properties of PMMA are significantly enhanced by

the incorporation of Glass fiber. Silane coupling

agents play a central role in improving bonding

between fillers and the resin matrix, and they

subsequently improved the resin’s properties.3

The fabrication of complete dentures using a

conventional method associated with certain

problems. To avoid this, computer-aided design/

computer-aided manufacturing (CAD/CAM)

system have been successfully introduced into

restorative dentistry and maxillofacial technology

to simplify the fabrication procedure and resolve

the associated problems.4-8

Panasonic Corporation of Japan presented, a

composite material comprised of zirconia and

alumina using ceria as a stabilizing material i.e.

NANOZR, and acquired pharmaceutical approval

in October 2006.2

Since it has a marked mechanical strength, and

long-term stability in the mouth, clinical application

for fixed prosthesis and dental implants has been progressing.9,10,11 The load-bearing ability of Yttria

partially stabilized tetragonal zirconia (Y-TZP)

has been shown to be equivalent to that of Co-Cr alloy,12 and NANOZR may also be applicable

for denture base material substituting for metal

because its mechanical strength is greater than

that of Y-TZP.

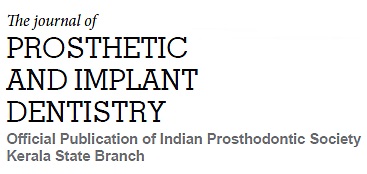

Ceramics have domain the field of dentistry for

the past 200 years.

Porcelain presents with poor mechanical properties

& has relatively low tensile strength, it is therefore

generally fused to a metal substrate to increase

its resistance to fracture.13 However, this metal

base creates metal ion discolorations that may

affect the aesthetics of the porcelain reducing

light transmission through the porcelain. Allergic

reactions and sensitivity to various metals is seen

in some patients. These disadvantages, led to

the development of new all-ceramic (metal free

ceramic) systems that do not require metal.14

Introduction of IPS EMPRESS 2, the metal free ceramic systems, resulted in a long lasting metal

free ceramic restoration.

CAD-CAM with its advancements occasioned

in the restoration with better esthetics, strength,

and ease of fabrication in single visit. In CAD/

CAM system the occlusion with the opposing tooth

requires manual refinement. With the advent of

newer software and advancement in systems,

this shortcoming is expected to be solved in the

near future.14

The most frequently used zirconia-containing

ceramic systems presently accessible in dentistry

are- yttrium cation-doped tetragonal zirconia

polycrystals (3Y-TZP), magnesium cation-doped

partially stabilized zirconia (Mg-PSZ) and zirconia-toughened alumina (ZTA) 15,16,17.

Crowns with zirconia core materials have higher

mechanical properties than other metal-free

restorations, Yttrium-oxide is added to pure

zirconia to control the volume expansion and

to stabilize it in the tetragonal phase, at room temperature.18 Yttrium-oxide partially stabilized

Zirconia (Y-TZP) has mechanical properties with

a flexural strength of 900 – 1200 MPa19 and high

fracture toughness, making it suitable for anterior

and posterior crowns as well as for long-span fixed

partial dentures.20

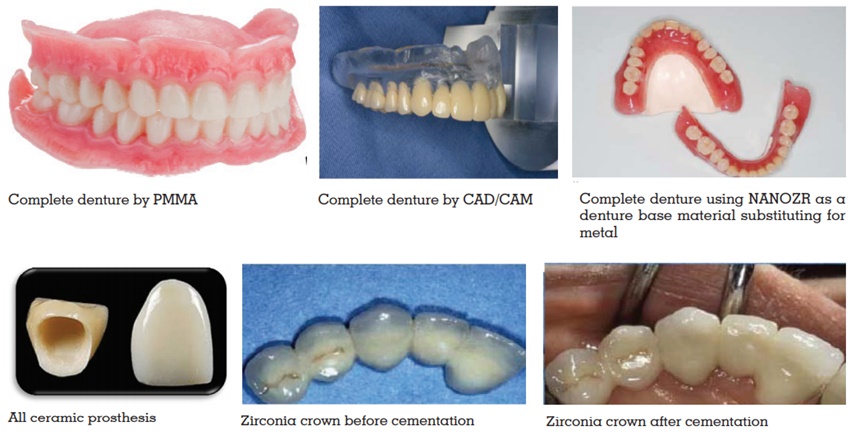

Dental prosthesis produces denture esthetics

that affects the beauty and attractiveness of the

person.21 Removable partial dentures (RPDs)

are the widely accepted treatment of choice for

most cases as it is both effective, affordable and

best treatment option for partial edentulism22 but

patients are concerned about the metal exposure

in cast partial dentures and hence worried about

the esthetic appearance.23,24 The traditional use

of the conventional metal clasps such as cobalt-chromium (Co-Cr), gold, stainless steel, and

titanium gives poor esthetic appearance due

to display in the oral cavity which hampers the

patient’s comfort.

Therefore a thermoplastic resin, Acetal resin

(polyoxymethylene [POM]), may be used as

an substitute clasp material. An unbreakable

thermoplastic resin, Acetal, was first proposed for

RPD material, in 1971. These injection moulded

resins were promoted mainly on its ability for

superior esthetics, which allowed the clasps to

better match the colour of abutment tooth.25

Thermoplastic materials were introduced in clinical

practice due to an aesthetically unacceptable

display of metal clasps, increased prosthesis

weight, the potential for metallic taste, and allergic

reactions to metals.26,27,28

PEEK permits RPD fabrication with metal-free

esthetic clasps and occlusal rests with better

occlusal stability owing to its white colour and

high strength.29

As an alternative RDP framework material,

a modified PEEK high performance polymer

(BioHPP) combined with acrylic denture teeth

and conventional heat-cured denture base acrylic

resin was used. BioHPP permits the fabrication of

metal-free clasps and occlusal rests, providing

occlusal stability and metal-free aesthetics due

to its white colour and high strength.29

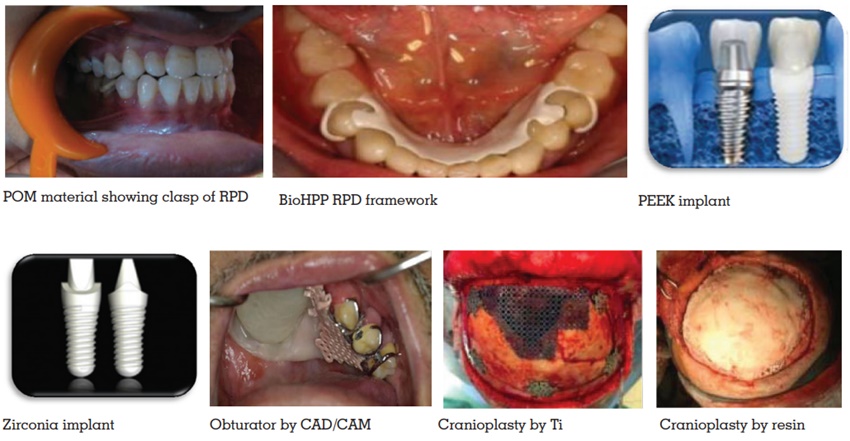

Inorder to replace missing teeth dental implants

are used. For this, Brånemark introduced Titanium

(Ti) and its alloys as dental implants at the

end of the 1960s.30 Ti materials possess good

physicochemical characteristics, mechanical

properties and biocompatibility.31,32 Ti materials

have an elastic modulus higher than that of bone

(titanium: 110 GPa; cortical bone: 14 GPa), and

the difference may result in inadequate stress-shielding, bone resorption, and implant fracture.33,34

Occasional metal hypersensitivity and allergies,

surface degradation and contamination related

to peri-implantitis, and scattered radiation are the

clinical problems accompanying Ti materials.35

The Ti materials due to its metallic appearance

compromises highly aesthetic restorations. There

have been a lot of researches to develop substitutes

for Ti dental implants, such as zirconia36,37, which

has a high elastic modulus and low temperature

degradation.38,39 Polymeric compounds, such as

polyetheretherketone (PEEK), which is a semi

crystalline linear polycyclic thermoplastic that

was developed in 197840.

Wolff’s Law says that the bone remodels according

to the load that has been applied to it. Due to

shielding of normal loads by the implant there is

reduction in volume of the bone around implant

known as stress shielding. Finite-element analysis

(FEA) of carbon-fiber reinforced PEEK (CFR-PEEK)

implants suggested that they could induce lesser

stress shielding than titanium41.

The mechanical and physical properties of PEEK

are similar to bone and dentin, so it can be used

for a number of applications in dentistry including

dental implants. Here the challenge is faced while

increasing the bioactivity of PEEK dental implants

without affecting their mechanical properties.

It is an attractive material for producing CAD-CAM fixed and removable prosthesis compared

to materials such as acrylic. Further research

and clinical trials are required to explore this

material and possible modifications for further

dental application.42

Recently, high strength zirconia ceramics have

acquired a place of attraction as new materials

for dental implants. They are inert in the body

and exhibit minimal ion release. Owing to its

higher fracture resilience and flexural strength,

Yttrium-stabilized tetragonal zirconia polycrystals

appear to offer advantages over aluminium oxide

for dental implants.43,44

The inflammatory response and bone resorption

induced by ceramic particles are less than those

induced by titanium particles which suggest its

biocompatibility.45,46

Its the artificial device used to replace missing

facial or oral structures. Now a days CAD CAM

device is used for this.

Advantages of using CAD / CAM are:

The viable options option for less tissue irritation and more patient comfort are the intra oral scanning of a hemi maxillectomy patient and the implementation of CAD/CAM techniques for obturator fabrication.48 Cranioplasties have been performed since the early 1950s49. Acrylic resin materials form an alternative to bone substitutes in dentistry. Due to the properties like dimensionally stability, nonconductivity and economical, acrylic resins are used in implant dentistry.50 Acrylic resin has some advantages over metal substances; it is easy to shape, lighter in weight, radiates less heat, and radiolucent.51,52

Keeping in mind the various hazards of using

metals as prosthetic materials and the awareness

and demand for aesthetics has lead to the

evolution of metal-free prosthesis which will soon

be the future of dental prosthesis. An adequate

knowledge about the same is essential amongst

the practitioners in order to bring them in practice

unlike other conventional materials.