Production stages are now becoming more automated in the field of dentistry. Over the last two decades, computer assisted designing and manufacturing of highly durable and aesthetically satisfying prosthesis become the centre of focus. CAD/CAM generated dental restorations have many advantages that include: the access to almost defect-free, prefabricated and controlled materials; an increase in the reproducibility and quality of the restorations and also data storage that commensurate with a standardized chain of production; it will provide an improvement in planning, increase in efficiency and improvement in precision.

Key words: standard transformation language, subtractive manufacturing, additive manufacturing, digital implant prosthesis, computer navigated surgery.

CAD-CAM is an acronym for COMPUTER

AIDED DESIGNING – COMPUTER AIDED

MANUFACTURING. Use of computer systems to

assists in creation, modification, analysis and

optimization of design. CAD-CAM usage in dentistry began in mid-1980s. CAD-CAM is a

field of dentistry and prosthodontics using CAD-CAM, to improve the design and creation of dental

restorations, especially dental prosthesis, including

crowns, inlays, veneers, onlays, fixed bridges,

dentures and fixed dental implant restorations.

CAD-CAM has become the centre of attention,

because of its potentiality to deliver a highly

durable and aesthetically satisfying restoration

on the same day of patient visit.

All CADAD-CAM system consists of three components.

A scanner or digitalization tool is used to transform object’s geometry into digital data, that can be processed by system.1 Basically there are two different type of scanners available:

In optical scanners white light projections or a

laser beam can serve as a source of illumination.1

the basis of this type of scanner is the collection

of three dimensional structures in a ‘triangulation

procedure’. In this system, the light source and

the unit containing the receptor are arranged in

a definite angle to another. Through this angle

the computer can calculate a three dimensional

data set from the image on the receptor unit2

.

Example: Lava Scan ST (3M ESPE, white light

projection), es1 (etkon, laser beam)

In mechanical scanners, the prepared master cast

is read line-by-line mechanically by means of a

ruby ball and the structure is measured three-dimensionally. The diameter of the ruby ball is

set to the smallest grinder in the milling system,

with the result that all data collected by the system

can also be milled.3,4

Example: Procera scanner from Noble biocare

(fig 1)

It processes data and, depending on the

application, produces a data set for the product

to be fabricated.2

Example: exocad, CEREC SW 4.5, TRIO software

Suite, Planmeca PlanCAD 6.0

Various data formats are used to store the data

for construction. The basically used format is

standard transformation language (STL) data.

It transforms the construction data set produced with CAD software into the desired product. They are of two types namely

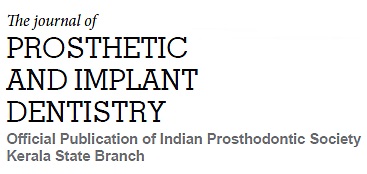

Subtractive manufacturing is a process by which 3D objects are constructed by cutting the materials from a solid block of material. Processing devices are classified based on the number of milling axes (fig 2):

X,Y,Z- 3 spatial directions, A- tension bridge, B

– milling spindle

The 3 axis milling device has degrees of movement

in all the three spatial directions. In this system

the mill path points are defined by X -, Y -, and Z

– values. All 3-axis devices applied in the dental

field can be able to turn the component by 180°

in the course of processing the outside and the

inside. A milling of axis divergences, subsections

and convergences, is not possible. This demands

a virtual blocking in such areas.1

Examples of 3-axis devices: in Lab (Sirona), Cercon

brain (DeguDent), Lava (3M ESPE).

In addition to movement in 3 spatial directions,

these devices also have rotatable tension bridge.

Hence, a large vertical height displacement into

the usual mould dimensions can be done during

bridge constructions and thus save material and

milling time.1

Eg: Zeno (fig 3)

With a 5-axis milling device there is also, in addition to the three spatial dimensions and the rotatable tension bridge (4th axis), the possibility of rotating the milling spindle (5th axis) . This enables the milling of complex geometries with subsections, as for example, lower jaw FPDs on converging abutment teeth (fig 4).1

Dry Processing:

Dry processing is applied mainly with respect

to zirconium oxide blanks with a low degree of

pre-sintering.5

This offers several benefits:

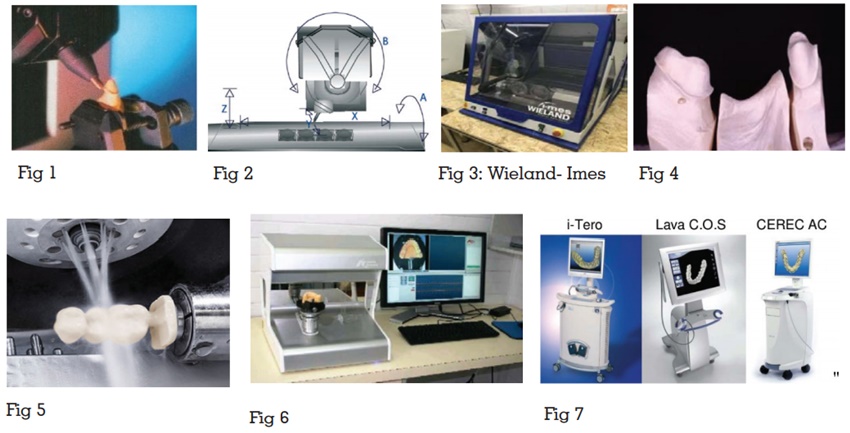

Wet processing:

In wet processing the carbide cutter or milling

diamond is protected by a spray of cool liquid to

prevent overheating of the milled material (fig 5). This kind of processing is necessary for all metals

and glass ceramic material and processing of

zirconium oxide ceramic with a higher degree

of pre-sintering. A higher degree of pre-sintering

will leads to reduction in shrinkage factor that in

turn will enables less sinter distortion.5

Examples:

Zeno 8060 (Wieland-Imes), Everest (KaVo), inLab

(Sirona).

It is known as 3D printing because it describe a

manufacturing approach that builds objects one

layer at a time, adding multiple layer to form an

object. It is also known as rapid prototyping. It can

be used for construction of metal structures either

directly in metals or metal alloys like RPD, FPD,

polymerized prosthesis and silicone prosthesis or

indirectly by lost wax process or printing in burn

out resins.

Three different production concepts are available in dentistry, depending on the location of each component of the system, it includes

All components of the CAD/CAM system are located

in the dental surgery. In this type of production,

the tooth preparation can be scanned intraorally

and by selecting appropriate materials, the dentist

can fabricate the restoration and cement it in a

single appointment.7

Example: CEREC System (fig 6)

In this system the impression or the master cast

will be send to the laboratory. Then the process of

scanning, designing and processing the restoration

will takes place in the laboratory.7

Example: i- Tero, Lava C.O.S, CEREC AC (fig 7)

In this system the data sets produced in the dental laboratory sent to the production centre, where restorations will be produced with a CAD/CAM device in the milling centre and the prosthesis will be sent to the responsible laboratory and to the dentist.7

CAD/CAM devices generally process the following

materials:

Metals:

At present chrome cobalt alloys, titanium, titanium

alloys are processed using CAD-CAM milling

devices.

Examples: Everest Bio T-Blank (KaVo, pure

titanium), coron (etkon: non-precious metal alloy).

Resin materials:

Used for the milling of lost wax frames for

casting technology. Used directly as crown and

FPD frameworks for long term provisional or for

full anatomical long term temporary prosthesis.

Prefabricated semi-individual polymer blanks

(semi-finished) with a dentine enamel layer are

also available (artegralim Crown, Merz Dental).1

Silica based ceramics

Grindable silica based ceramic blocks are used

by CAD/CAM systems for the manufacturing of

veneers, inlays, onlays, partial crowns and full

crowns (anatomically partially reduced, fully

anatomical). Various manufacturers now offer

blanks with multicolored layers [IPS Empress

CAD Multi (Ivoclar Vivadent), Vitablocs TriLuxe

(Vita)], for the production of full anatomical crowns.

Lithium disilicate ceramic blocks are particularly

important and are used for full anatomical anterior

and posterior crowns, for copings in the anterior

and posterior region and for three-unit FPD

frameworks in the anterior region due to their high

mechanical stability of 360 MPa.8,9 Glass ceramics

are particularly well suited to chairside application

as a result of their translucent characteristics, similar to that of natural tooth structure.10

Infiltration ceramics

Infiltration ceramics are processed in porous,

chalky condition as grindable blocks and then

infiltrated with lanthanum glass.

Aluminium Oxide (Al2

O3

)

Aluminium oxide is indicated in the case of crown

copings in the anterior and posterior area, primary

crowns and three-unit anterior FPD frameworks.12

Examples of grindable aluminium oxide blocks:

InCoris Al (Sirona), In-Ceram AL Block (Vita).

Yttrium Stabilised Zirconium Oxide

(ZrO2

, Y-TZP):

Zirconium dioxide is a high-performance oxide

ceramic with high flexural strength and fracture

toughness compared with other dental ceramics

offer the possibility of using this material as

framework material for crowns and FPDs, and,

in appropriate indications, for individual implant

abutments.13

Examples of Zirconium oxide blocks: Cercon

Smart, Lava Frame (3M ESPE), Ceramics.

Digital impression:

It is a positive replica of the oral structures.

For the success of fixed partial dentures like

ceramic restorations internal fitness and

marginal adaptation are important.14 As there

is no dimensional inaccuracy or changes in the

impression or the cast because the impression will

an optical impression and the cast are 3D printed/

milled using polyurethane or styrofoam material.

No need for disinfection of the impression, it is

easy to sore and comfortable for the patients and

it reduces the patient treatment time.

Fixed Prosthesis:

The production of long-term temporary prostheses,

from single unit to full bridge, coping, 3/4th crown,

full crown, veneers is possible, as a result of the

use of a virtual wax up on the computer, become

faster, more convenient and more predictable.1

Removable Prosthesis:

Commercially available CAD/CAM dentures

include

Using CAD/CAM it is possible to deliver the

complete denture in two visits. Less chairside time

needed and is more comfortable for the patient.15

Digital Implant Prosthesis:

Numerous implant planning softwares are

available which aids in accurate placement of

implants.

The two types of computer assisted implant

surgeries includes,

Computer guided surgery:

CAD/CAM designed surgical guide is used for

accurate placement of the implants.16

Computer navigated surgery:

The computer navigated surgery is a direct method,

where the position, angulations and the distance

of implant to the vital structures can be viewed

directly on the screen during implant placement.

It helps in more accurate placement of implants.

CAD/CAM system enables the dentist to provide

highly durable and esthetically satisfying

restorations on the same day of patient visit.

It is more time saving and comfortable for the

patient. The introduction of new systems and the

evolution of current systems demonstrate expanded

capability and improved quality of the prosthesis.