Loss of tissue in maxilliofacial region is so common due to various reasons like trauma, cancer surgeries etc…With the arrival of tissue engineering methods viable tissues can be “cultivated” in the lab and can be used for curing the defects, novel method of 3D bioprinting is the new hope in tissue engineering.

The ability to print biological tissues opposite

to traditional 3D plastic and metal printing

has resulted in the birth of the new bio printing

and Tissue Engineering research field. 3D bio

printing is a computer-aided deposition of cells,

biomaterials and biomolecules. The advantage

of 3D bio printing compared to traditional tissue

engineering is assembling cells, biomaterials and

biomolecules in a spatially controlled manner to

reproduce native tissue. In the future, due to highresolution characteristic of printing technology with novel printable biocompatible materials or ‘inks’,

autologous tissue will be 3D printed with macroand micro-architecture for reconstruction. The focus

is by controlling the micro and macrostructures to

replicate complex native-like tissue architecture

more reliably than by conventional methods. The

wide synergy of research on biomaterials and on

3D bio printing may enable restoring the form

and functional reconstruction of OMF anatomy

in the near future. 3D bio printing avoids donor

site complications and immunosuppression. The

main obstacles for wider use for 3D bio printing

are related to biology, technology and regulatory

issues.

Traditional 3D printing is relatively simple and

can be performed by the home computer using

the proper software. For medical use, 3D digital

data are acquired from computed tomography,

magnetic resonance imaging, or laser scanning.

These data can be manipulated by CAD–CAM

software and be converted into Stereolithographic

format for printing. Fabrication of solid bio model

is carried out under the computer guidance to accurately and in a controlled manner deposit

biological materials in a layer-by-layer fashion. 3D

bio printer uses a nozzle to deposit biomaterials

and cells according to xyz-axis to create the

structure required. Fabricated solid model is then

cultured in a bioreactor under specific conditions to

produce specific and designed tissue engineered

vital tissue.

Cells derived from patients preferably stem

cells are cultured in optimum conditions. These

cells are provided with adequate growth factors

enabling them to grow and multiply. When they have multiplied to enough numbers they are

collected formed into spheroids and loaded into

a cartridge to create a bio ink.

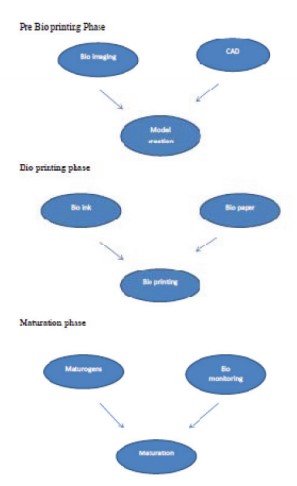

Bio printing involves three phases

Although anatomical and functional bone identical

to original jawbone cannot be produced at the

present, there is good evidence that Tissue

Engineered bone identical to missing bone part

will be available in the near future. This is an area

that could revolutionize the oral and maxillofacial

reconstruction in near future.