Bioceramics are an important subset of biomaterials which act as an excellent bone substitute which is been used in many fields of medicine. Bioceramics range in their biocompatibility from the ceramic oxides, which are bioinert, to the other extreme of bioresorbable materials, which are eventually replaced by the body after they have assisted the repair of cells. Its application in dental implants has gained interest in the past two decades. This review is attempted to emphasize the approaches done in bioceramic materials for use in dental implants.

Key words: Bio ceramics, zirconium, bioimplants

The efforts to restore completely and partially

edentulous arches have been practiced by

clinicians since centuries. By the introduction of

dental implants it has become the mainstream

practice and is clinically accepted as the desired

treatment modality for the patients. Implant

biomaterials, especially bioceramics have provided

the research and dental clinical professionals with

a new essence of interest for over past two decades.

Biomaterial by definition is a “non-drug substance suitable for inclusion in systems which augment or

replace the function of bodily tissues or organs.”

Bioimplants are prosthesis made for regularising

the physiological function of body and bioceramics

represent one classification of the bio implant

based on the material used.

Plaster of Paris (CaSO4.H2O) – first widely evaluated

bioceramic

1892—Dressman published first report on the use

of plaster of Paris to repair bone defect.

1920—first successful use of Tricalcium phosphate

1930—polymeric implants introduced (Rock 1933-

alumina)

1960s—1970s – interest in bioceramic invention

by work of Hulbert and co-worker.

1969-1971—bioactive glass ceramic first introduced

by L.L Hench.

1988—plasma sprayed hydroxyapatite first used

by Herman

The American dental association outlines some acceptance guidelines for dental implant biomaterials:

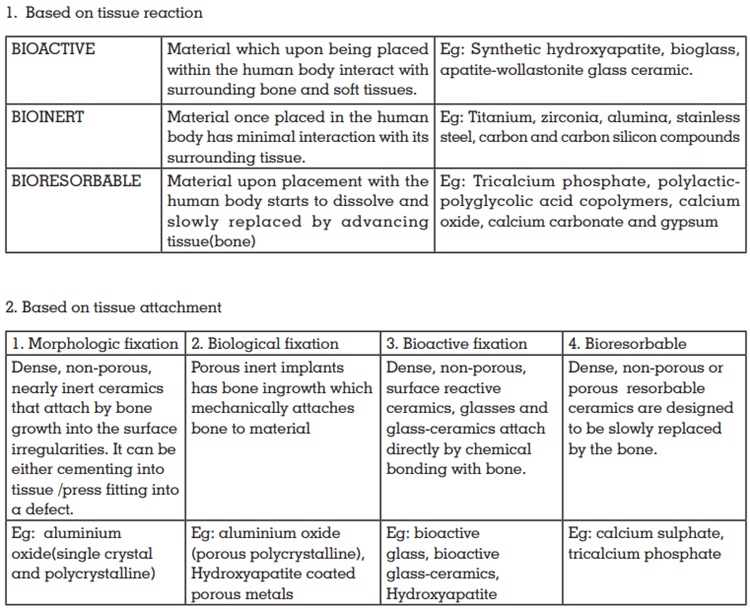

Ceramics used for the repair and reconstruction of

diseased or damaged parts of the musculoskeletal

system termed as bioceramics, maybe categorized

as follows:

Bioglass / Glass Ceramics:

Discovery of Bioglass was by Hench and Wilson. It

was first introduced in the year 1971. The glasses

containing specific proportions of silica, sodium

oxide, calcium oxide and phosphorus pentoxide

are termed bioactive. The nucleation and growth

of crystals within the glass converts the glass to

glass ceramics, which retain the bioactivity. They

have high mechanical strength, fast setting ability,

low resistance to tensile and bending stresses and

extreme brittleness. They chemically bond to bone

due to formation of calcium phosphate surface

layer. Ceravital silica is a type of glass ceramic.

Hydroxyapaptite:

It is chemically calcium phosphate [Ca10 (PO4)6(OH)2] and is similar to the mineral component

of bones and hard tissues. Hydroxyapatite was

successfully used as an implant material in 1988

soon after the bioactive glasses were developed.

The hydroxyapatite in powder form is excellent

bone filler. They have calcium to phosphorus

ratio of 1.67 and is the most stable phase of

various calcium phosphates. The preparations

of hydroxyapatite powders include wet methods

and solid state reactions. Hydroxyapatite is stable

in body fluid and in dry or moist air upto 1200°C

and does not decompose.

Plasma sprayed hydoxyapatite was first used

by HERMAN in 1988. It is used as coatings on

implants.

Alumina:

Alumina is a highly inert material which was

introduced by Rock in 1933. It was first used as an

implant material in the 1970s. It has excellent wear

resistance and surface hardness. Alumina exists

in many forms and these arise during the heat

treatment of aluminium hydroxide or aluminium

oxy hydroxide. However the body recognises it as a foreign material and attempts to isolate it

by forming a non adherent fibrous layer which

is considered as a drawback in the use of this

material.

Titanium:

Titanium was first introduced in the year 1789

by Wilhelm Gregor. Due its excellent property

of biocompatibility and its ability to form stable

oxides it has been successfully used as an implant

material in the recent years. Three different oxides

formed on titanium surface are TiO (Anastase),

TiO2 (Rutile) and Ti2O3 (Brookite).

Titanium oxide layer exhibits low level of charge

transfer. Its modulus of elasticity of is half of the

other alloys 5 to 5.6 times greater than bone that

helps in its uniform stress distribution.

Zirconia:

Zirconium dioxide was first extracted from the

mineral Zircon (Zirconium Silicate ZrSiO4) by

the German chemist Martin Heinrich Klaproth

(1743-1817). It was in 1969 the first scientific study

of outstanding biomedical properties of zirconia

emerged and subsequently it was found that

alloying zirconia with oxides of yttria, calcia and

magnesia made it stable. This discovery also led to

the use of the so-called transformation toughening

of zirconia to produce ceramics with unsurpassed

crack resistance (‘ceramic steel’).

Zirconia was successfully used as implant material

in 1960s. It has high flexural strength, fracture

toughness and ability to be polished to a superior

surface than alumina. Zirconia implants also

absorb water and hence become prone to fracture.

Yttrium stabilised tetragonal polycrystalline

zirconia:

This form of zirconia offers best mechanical

properties.

Carbon and carbon silicon

compounds:

Vitreous carbon and carbon compounds are used

in implantology since 1970. Carbon is a versatile that exists in many forms. The biocompatibility

of carbonaceous material to bone indicates its

use in orthopaedic implants. However due to the

intrinsic brittleness and low tensile strength, carbon

compounds have limitations for use in major load

bearing applications.

Calcium phosphate ceramics:

Calcium phosphate ceramics was first commercially

used as implant material in 1980s. They have

biochemical composition similar to bone and

exhibit direct chemical bonding to surrounding

bone. Therefore they are used as implant material

to be gradually substituted by newly formed bone

and get integrated with the host bone. The first

stage is interaction with collagen in bone and

then accumulation of protein and cells on the

surface of the biomaterial and this is followed by

the resorption of the material and finally bone

formation.

A subclass of these ceramics is tricalcium

phosphate ceramics. They are extensively used

owing to its biocompatibility characteristics.

They also have an added advantage of being

resorbable.

Other calcium phosphate compounds include:

Titanium-Zirconium alloy (Straumann

ROXOLID)

Narrow diameter implants (Roxolid®, Straumann, Basel, Switzerland) has recently been introduced

in dentistry. This alloy which has a metallic gray

appearance contains 83-87% titanium and

13-17% zirconium. It has superior mechanical

characteristics over commercially pure (CpTi) and

Ti-6Al-4V, as well as increased fatigue strength.

The addition of zirconia to titanium leads to

excellent osseointegration capabilities. The

biocompatibility of titanium-zirconium alloy is

also more when compared to pure titanium.

In order to maintain the clean oxide layer with

its hydrophilic properties the Titanium-Zirconium

implants are manufactured with the SLActive

surface like the titanium SLActive implants: Sand

blasted, acid etched and then stored in 0.9% NaCl

solution.

Polyetheretherketone (PEEK)

For patients with high aesthetic requirements,

the new material known as PEEK (polyether ether

ketone) is recommended as it is aesthetic, stable,

biocompatible, lighter degree of discoloration.

BioHPP (High Performance Polymer) is based

on polyether-ether-ketone (PEEK) polymer and

was introduced as dental material for precise

prosthetic restoration fabrication. BioHPP has a

low specific weight that permits the fabrication

of lighter prostheses which provides high patient

satisfaction and comfort during masticatory

function.

BioHPP reduces the stress caused by natural

forces as well as the forces attributed to the

prosthetic restorations. While comparing with

titanium, zirconium or ceramic, rehabilitation using

BioHPP significantly reduces the peak masticatory

forces both for axial and oblique movements. This

property provides a positive effect for the patient

and also it extends the durability of the restoration.

Silicon nitride (Si3N4) ceramics

Titanium has been the choice for dental implant fabrication for many years owing to its superior

mechanical and biological performances. The

increasing demand for metal-free restorations has

led to development of ceramic-based implants

like Zirconia and other alternative biomaterials

like PEEK and silicon nitride

Silicon nitride has following properties:

Silicon nitride derives its strength and toughness

through its microstructure, which is mainly

composed of asymmetric needle-like interlocking

grains surrounded by a thin (<2mm) refractory

grain-boundary glass. Unlike other ceramics, there

is no phase transformation is involved.

The primary requisite for a dental implant

material is to be biocompatible and have

superior biomechanical properties. Various

implant biomaterials like titanium, zirconia, etc

are used in this aspect which provides excellent

osseointegration with the bone. The recent

developments in biomaterials having high esthetic

performance like polyetheretherketone and silicon nitride have given way for more future research

which could be of great interest for oral use.