A precise impression is crucial for ensuring a perfect fit of indirect restorations. However, for many clinicians, obtaining an accurate impression for fixed prostheses remains one of the most challenging aspects of restorative dentistry, despite advances in elastomeric materials. The effectiveness of newly developed elastomeric polymer Vinyl Polyether Siloxane, which combines the properties of polyether and polyvinyl siloxane (PVS) elastomers, has been a subject of interest in recent studies. This review aims to elucidate the material properties of vinyl polyether siloxane through a comprehensive analysis of current scientific literature.

Key words: vinyl polyether siloxane, polyether, polyvinyl siloxane, elastomeric impression materials, fixed prostheses

An accurate impression is the first most important

step in the procedure of obtaining a perfect

restoration. It is the aim of the impression to

produce a dimensionally stable ‘negative’ which

can serve as a mold for a cast.1

The accuracy of impression materials is crucial

for producing a well-fitting definitive restoration,

relying on both dimensional stability and

detailed reproduction. Various factors affect the

dimensional accuracy, including periodontal

health, oral hygiene, technique, tray selection,

and material properties. Additionally, the

material’s ability to flow and conform to oral

tissues, as well as its capacity to properly wet

moist surfaces, plays a key role in achieving a

precise impression. Any inaccuracies during

this process can lead to errors when transferring

information to the dental laboratory, ultimately

compromising the fit and adaptation of the final

restoration.2

Among available elastomeric materials, the

vinyl polysiloxanes (VPS) and polyethers (PEs)

are used most frequently.3 Traditional additional

silicones were hydrophobic; due to which

accuracy of impressions was questionable.

The newer ones have added surfactants to

counteract this. Polyether, on the other hand, is

hydrophilic and records good detail, but it is the

stiffest among all elastomers.1

Combining Polyether (PE) with Polyvinyl

Siloxane (PVS) to create hybrid materials offers

several mechanical advantages. Due to the

similar mechanical properties of both materials,

this combination can enhance tensile and tear

strength. The synergistic effect may improve

performance in dental impressions, where

flexibility and durability are essential.4 This newer

elastomer that has been developed is called

as vinyl polyether siloxane (VPES) combining

features of both addition silicone and polyether

were commercially introduced in 2009 as

stated. This new elastomer boasts of immediate

hydrophilicity, at the same time combining

favorable characteristics of both polyether and

vinyl polysiloxane.1 This article aims to explore

new impression material that are both effective

and efficient in achieving predictable, accurate,

and high-quality impressions in dental practice.

In the 1950s, polysulfides and condensation

reaction silicones (C-type silicones) were reliably

used in fixed prosthodontics. In the late 1960s,

polyether, a hydrophilic material cured by cationic

ring-opening polymerization, was introduced.

With its excellent mechanical properties, good

elastic

recovery, and minimal shrinkage,

polyether outperformed hydrocolloids and

C-type materials. A decade later, hydrophobic

addition-cured silicones, or poly(vinyl siloxane)

(PVS), were introduced, with their hydrophobicity

reduced by adding surfactants. PVS is renowned for its high dimensional stability across time

and temperature, as well as its superior

elastic recovery, even in moist environments.

According to Christensen in 1997, “The past 20

years have brought significant improvements

in both polyether and PVS categories, making

them the most widely accepted materials for

prosthodontic applications.” By 1997, the three

dominant categories of impression materials for

fixed, removable, and implant prosthodontics

were addition reaction silicones, polyether, and

reversible hydrocolloid, in that order of usage.1

A novel impression material, Vinyl Polyether

Siloxane (VPES), has recently been developed

through extensive research and testing of various

properties. This innovative hybrid combines the

hydrophilic characteristics of polyether with the

dimensional stability and elastic recovery of

polyvinyl siloxane (PVS), resulting in a material

that offers superior flow, tear strength, and

accuracy in moist environments without the need

for surfactants.

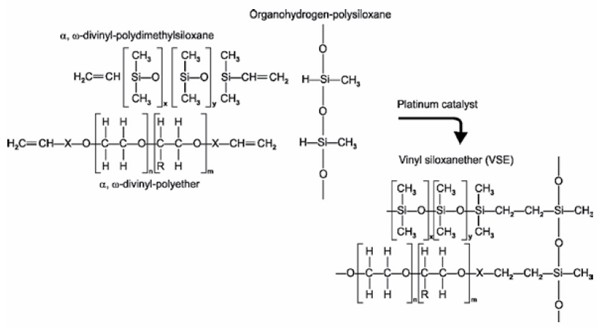

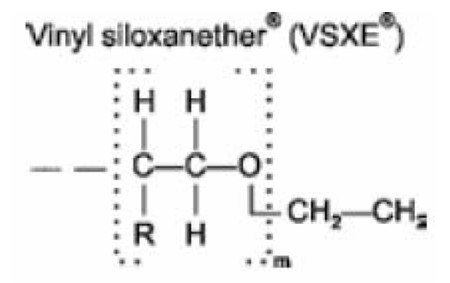

It is a new chemical compound developed by

combining polyether polymer and vinyl groups

of VPS as shown in the figures below.1

Figure showing Vinyl polyether siloxane

molecule below:1

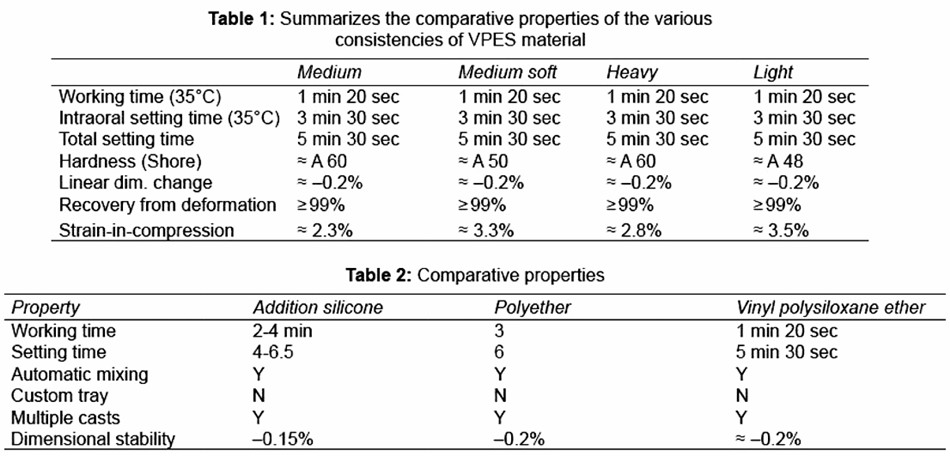

The properties of vinyl polyether siloxane (VPES)

material and comparisons between VPES,

addition silicone and polyether are summarized

in Tables 1 and 2.1

The Vinyl Polyether Siloxane (VPES) impression

material is designed exclusively for the one-step

multiple-mix technique, ensuring optimal results

in dental impressions. This technique involves

the use of a custom tray and the simultaneous

application of two viscosities: heavy body and light body materials. The heavy body is placed

in the tray, while the light body is injected around

the prepared tooth to capture fine details. The

combination of these viscosities allows for

accurate tissue recording and a precise fit for

definitive restorations.

Some of the specific indications according to

viscosity are listed below.1

Medium Viscosity

Heavy Viscosity

Light Viscosity

Dimensional Stability

Stober et al evaluated a study on the Accuracy

of newly formulated fast-setting elastomeric

impression materials and stated that vinyl

siloxanether monophase impressions and vinyl

siloxanether dual-viscosity impressions display

acceptable accuracy for clinical use with

immersion disinfection, since the results for vinyl

siloxanether were comparable to the results for

representative polyether and vinyl polysiloxane

materials.10

Techkouhie A et al conducted a study on Surface

detail reproduction of elastomeric impression

materials related to rheological properties

suggest that PVS has the smallest change

(−0.15%), followed by polyether (−0.2%). The

vinyl siloxane ethers have a dimensional change

of ≈ –0.2% which is acceptable.11

Nassar U et al evaluated the dimensional stability

of vinyl polyether silicone (VPES) impressions as

a function of delayed-pouring time for up to 2

weeks after performing a recommended clinical

disinfection procedure. It was concluded that the

Casts produced from a disinfected regular set

VPES (EXA’lence 370 monophase) demonstrated

excellent dimensional stability at different pour

times and were comparable to the tested VPS

and PE impression materials.5

Surface detail reproduction

Rabeeba PK et al compared and evaluated

the surface detail reproduction and effect of

disinfectant and long-term storage for 2 weeks

on the dimensional stability of hybrid material

Vinyl polyether silicone (VPES) with its parent

Polyvinyl siloxane (PVS) and Polyether (PE)

impression materials and the results concluded

that the newer material VPES was observed to be both dimensionally stable and capable of

producing good surface detail reproduction.2

Tear strength

Tear strength is influenced by the chemical

composition, consistency, and manner of removal

of material. A rapid rate of force application

during removal usually increases the tear

strength. Pandey P et al evaluated a study on

Mechanical Properties of a New Vinyl Polyether

Silicone in Comparison to Vinyl Polysiloxane

and Polyether Elastomeric Impression Materials

and the results indicated that the tear strength

of vinyl polyether siloxane was better than

polyether and vinylpoly siloxane.3

Tensile strength

Pandey P et al evaluated a study on Mechanical

Properties of a New Vinyl Polyether Silicone in

Comparison to Vinyl Polysiloxane and Polyether

Elastomeric Impression Materials and the results

indicated that the new vinyl polyether silicone

had better tensile strength than polyether.3

Flexibility

Vinyl polyether siloxane tested was found to

be more flexible with high tensile energy in a

study evaluated by Pandey P et al. This material

can be preferred in cases with undercut areas

favoring the removal of impressions without tear

and distortion.3

Effect of Disinfectant

Rabeeba PK et al compared and evaluated

the surface detail reproduction and effect

of disinfectant and long-term storage for 2

weeks on the dimensional stability of hybrid

material Vinyl polyether silicone (VPES) with its

parent Polyvinyl siloxane (PVS) and Polyether

(PE) impression materials. According to the

disinfection guidelines, it is suggested that

addition silicone impressions can be disinfected by immersion without affecting its accuracy

and surface detail reproduction. Surface detail

reproduction is observed to be enhanced by

the use of 2% acidic glutaraldehyde solution.

In the present study all the impressions were

disinfected in 2.45% glutaraldehyde solution

for a duration of 30 minutes whereas the non

disinfected ones were kept in distilled water for

30 minutes. Among the disinfected groups Vinyl

polyether silicone showed the least dimensional

changes on 0 day, 7 days and 14 days of storage

compared to polyvinylsiloxane and Polyether.2

Hydrophilicity

The hydrophilic or wettable characteristics

of impression materials also contribute to

passively fitting impressions. The hydrophilicity

was measured by determining the contact

angle of a drop of water on the material under

observation. Singer et al. reported that PVES

demonstrates improved hydrophilicity and

wettability compared to PE and PVS, and these

observations were also consistent with other

studies.4 Heuttiget al. reported the highest

hydrophilicity of PVES, with a mean contact

angle of 16.8° among eight samples.12

Surface quality

Rabeeba pk et al conducted a clinical

comparison of quality of vinyl polyether silicone

impressions with polyvinyl siloxane impressions

using one-step impression technique and the

results showed that the new hybrid material vinyl

polyether silicone displayed acceptable surface

quality and handling properties for clinical use

using one-step impression technique.6

Vinyl polyether siloxane represents the dawn

of the next generation of materials, overcoming

the drawbacks of all previous impression

materials. This systematic review provides a clear understanding of the properties of novel

vinyl polyether siloxane hybrid impression

materials. Vinyl polyether siloxane

has

significantly better tensile strength and provides

impressions with fewer defects compared to

polyether and Polyvinylsiloxane. Vinyl polyether

siloxane exhibited better wettability and contact

angle with water than Polyvinyl siloxane and

Polyether. This makes it an excellent alternative

to Polyvinylsiloxane, in which moist conditions

are prevalent in the clinical setting. This makes

vinyl polyether siloxane the preferred material

for dental impressions. It can be concluded

that vinyl polyether siloxane hybrid elastomers

eliminate the drawbacks of Polyether and

Polyvinylsiloxane, providing a novel impression

material with superior tensile strength,

hydrophilicity, and dimensional accuracy in one

place. It is also worth noting that vinyl polyether

siloxane exhibits satisfactory elastic recovery

and detailed reproduction, as individual studies

indicate. However, further researches can be

done for a more detailed analysis of all the

properties.