Introduction/Background. Errors can be introduced in

implant placement when using stereolithographically

manufactured fully limiting surgical guides due

to various factors, and at various steps, such as

during designing and manufacturing of surgical

guides (intrinsic error), due to built-in variations in

design of mechanical components of guide systems

and implant dimensions (inherent error) or due to

placement error by the operator (operator error).

Aim. The aim of this study was to evaluate influence

of various factors on implant position when using

these guides.

Materials and Methods. Prosthetically-driven implant

positions were planned with pre-operative cone

beam computed tomography (CBCT) data and

digital scans using a computer aided designing

(CAD) software. Static guided implant surgery

was performed under local anaesthesia using

fully limiting mucosa-supported surgical guide.

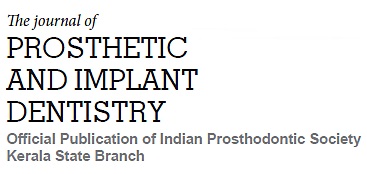

Pre-operative and post-operative CBCTs were superimposed using surgical sleeve as a reference

to evaluate the placement error by operator (N=12).

To evaluate intrinsic error, standard tessellation

language (STL) files of the virtual design of the surgical

guides and the STL file obtained after scanning the

3D printed stereolithographic surgical guides were

superimposed. Inherent error was calculated using

a geometric model.

Results. Intrinsic error was observed to be a major

contributing factor in angular deviation of implant,

linear deviation observed at implant shoulder as well

as at implant apex. Operator error was observed

to be a major contributing factor for mean vertical

deviation observed at apex of implant.

Conclusion. This study showed that accuracy of

implant placement was largely influenced by

discrepancies introduced during designing and

manufacturing of stereolithographic surgical guides

as compared to other sources.

Key words: Stereolithographic surgical guides, error, implant placement, static guided surgery

Static guided fully limiting surgical approach for

implant placement enables clinicians to perform

implant surgeries with improved accuracy, ease,

significantly lesser trauma to the tissues and in

shorter time duration.1-6 The precision of such

systems is of paramount importance and minor

discrepancies can result in subsequent surgical

as well as prosthetic complications.7

Errors can be introduced due to discrepancies

in designing, manufacturing of guides, built-in

design variations of mechanical components

of guide systems and implant dimensions or

due to operator related causes.8-22 Thus, the

cause of overall error in final implant position

is multifactorial and would be a cumulation

of errors introduced due to above-mentioned

factors.23-24

Hence, the purpose of this study was to evaluate

the influence of various factors on final implant

placement when using stereolithographic fully

limiting surgical guides. The null hypothesis

was that no error would be introduced in implant

placement due to various factors.

This study was conducted after obtaining pre-requisite approval from the institutional ethical

committee. Informed consent was obtained from

the patients included in this study.

The following variables were defined for the

purpose of this study:

Intrinsic Errors (ItE): Error introduced during

the designing and manufacturing of the

stereolithographic guides.

Inherent Error (IhE): Error introduced as a

result of built-in variations in the design of

mechanical components of fully limiting surgical

guide systems as well as variations in implant

dimensions.

Placement error by Operator (OE): Error

introduced while implant placement as a result

of operator’s skill and experience in different

clinical situations.

Angular deviation of implant axis: Angle in

degrees between the central axis of the implant

in the digitally planned position and the central

axis of the implant in the final position.

Linear deviation at implant shoulder: The

distance between the central axis of the implant

at the shoulder in the digitally planned position,

and the central axis of implant in the final

position.

Linear deviation at implant apex: The distance

between the central axis of the implant at the

apex in the digitally planned position, and the

central axis of implant in the final position.

Vertical deviation at implant apex: The vertical

distance between the apex of the digitally

planned position of implant and the horizontal

plane from the apex of final position.

The sample size calculation was done based

on the standard deviation values obtained

from a previously conducted study by Geng

et al24 using the formula n=Z2 SD2/d2 where,

n= Desired sample size, Z= Standard normal

deviate (1.96), SD= Standard Deviation, d=

degree of accuracy required (0.02). A minimum

sample size of 5 implants was calculated to get

statistically significant results.

This study included a total of 13 implants placed

using mucosa-supported stereolithographic

fully limiting surgical guides (DIOnavi Digital

Navigation Implant system; DIOnavi). Pre-requisite parameters for inclusion in the study

were adequate bone volume as seen on CBCT,

D2 or D3 quality bone, adequate mouth opening

with a straightforward or advanced Surgical

SAC classification.25 Implant sites requiring bone

augmentation and sinus elevation procedures

were excluded.

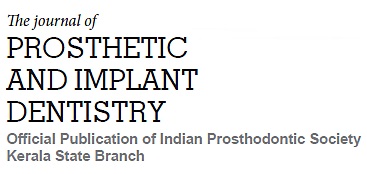

Pre-operative CBCT data and digital scans

of a completely edentulous patient who was

indicated for full mouth implant placement was

obtained. Prosthetically-driven implant positions

were planned using a computer aided designing

(CAD) software (Implant Studio; 3Shape)

(Fig.1). Stereolithographic surgical guides were

subsequently designed and 3D printed (Probe;

DIO Inc) using a commercial printable resin

(DIOnavi-SG; DIO Inc). The implant placed in

maxillary right second premolar region was excluded from the study since indirect sinus

elevation procedure followed by conventional

implant placement was performed in this region.

Static guided implant surgery was performed

under local anaesthesia. The fully limiting

mucosa-supported surgical guides were placed

intraorally and checked for fit. The guide was

secured firmly using fixation screws. The tissue

punch was followed by the bone-flattening drill.

A pilot drill of 2.0-mm-diameter along with the drill key was used to prepare implant site. The

implant osteotomy was then completed using

a series of sequential drills as per the protocol

provided (DIO Navi Guide; DIO Inc). Implants

were then placed with the surgical guide secured

in place (implant dimension: 13 mm X 3.8 mm in 11,13,21; 11.5 mm X 3.8 mm in 31,33,43; 11.5

mm X 4.5 mm in 44; 10 mm X 4 mm in 23; 10

mm X 4.5 mm in 34,36,46; 8.5 mm X 4 mm in

25 regions respectively). A post-operative CBCT

was taken immediately after implant placement

prior to removal of the surgical guide. This

post-operative CBCT data was superimposed

onto the pre-operative virtual implant planning

data using surgical sleeves as a reference to

calculate the error introduced by the operator

while implant placement using a CAD software

(Implant Studio; 3Shape) (Fig. 2).

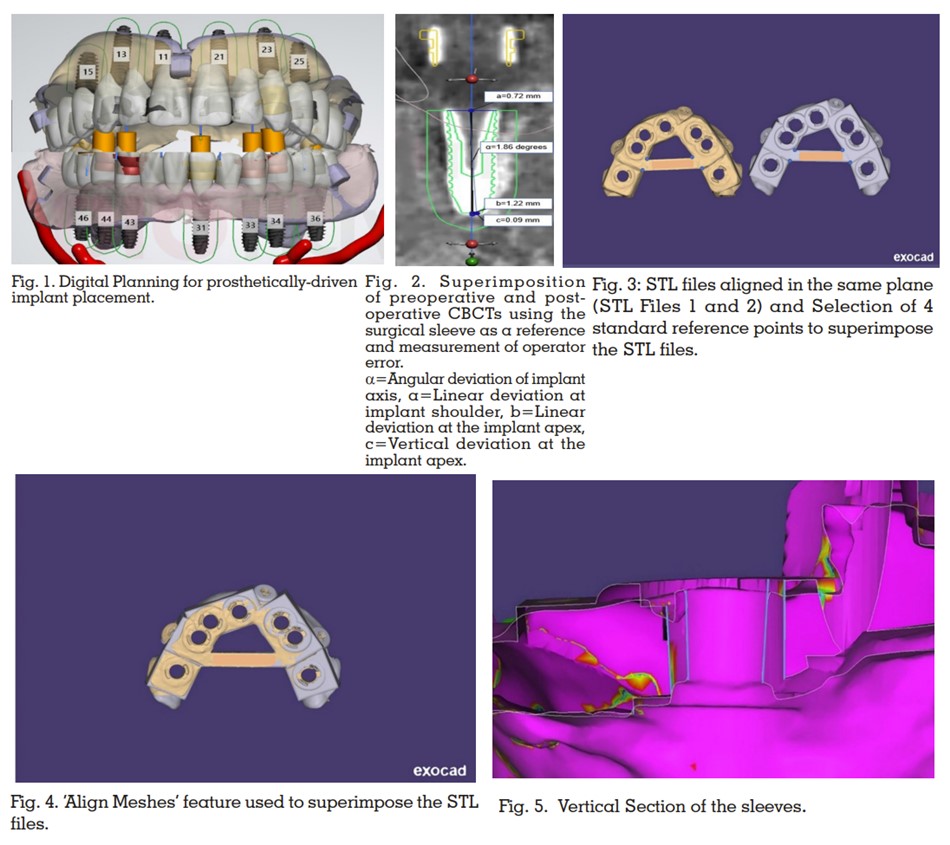

To evaluate ItE, the standard tessellation

language (STL) files of the virtual design of

surgical guides and the STL file obtained after

scanning the 3D printed stereolithographic

surgical guides were superimposed using

a computer-aided design software program

(exocad; exocad GmbH). The Align Meshes

feature was used to superimpose the 2 STL files

using 4 points on the central bar of the surgical

guide as a standard reference (Fig 3-4). The

methodology followed was exactly as previously

explained by Shah et al.7

The “Measurement

Tool” was used to make angular and linear

measurements between the margins of the

sleeves at the point of intersection of the planes

and sleeve margin mesially, distally, buccally,

and lingually by using the Color Map feature as

a guide (Calibrated from 0 to 50 mm with 5-mm intervals) (Fig 5).7

Formulas provided by Shah et

al7 were used to calculate the linear deviation at

the shoulder and apex of the implant as well as

the vertical deviation at the apex of the implant.

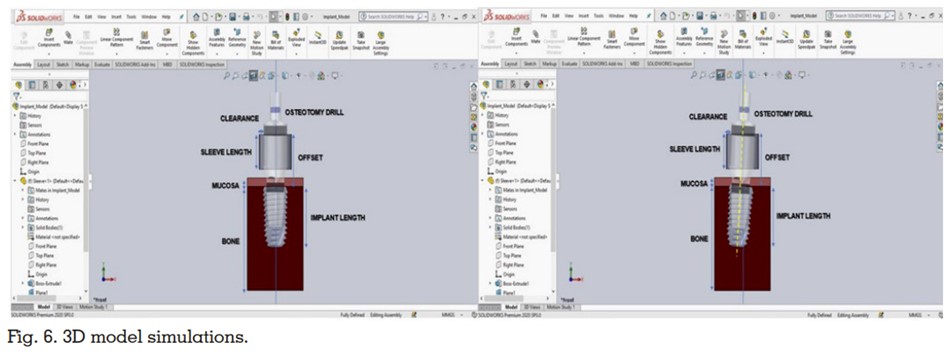

To calculate the IhE, this study utilized a CAD

software software (SOLIDWORKS® 2021

Software; SOLIDWORKS) and a geometric

model. A 3D CAD model was designed to assess

and evaluate the errors introduced during

implant placement by varying the design of

mechanical components of the surgical guide

as well as the implant dimensions (Fig. 6). For

designing this 3D CAD model, the standard

tessellation language (STL) files of the metal

sleeve, implant and the final drill of a commonly

used static guided implant system (DIOnavi

Digital Navigation Implant system; DIOnavi)

were obtained via scanning of the respective

components using a dental table-top scanner

(MeditT300; MEDIT).

The static guided surgery was then simulated

using a CAD software (SOLIDWORKS® 2021

Software; SOLIDWORKS). The “assembly” as

well as the “plane and angle orient” feature was

used to assemble and orient the individual STL

files with respect to each other. The dimensions

of the surgical guide as well as the implant were

varied to evaluate their effect on final implant

position. Clearance, offset, sleeve length, and

implant length were identified as the 4 factors which affected the implant position and were

considered further.

Clearance: The difference between the inner

diameter of the metal sleeve and the diameter of

the shaft of the drill.

Offset: The distance between the occlusal

surface of the metal sleeve and the shoulder of

the implant. Offset is sleeve length plus distance

between the sleeve base and implant shoulder.

Sleeve length: Total length of sleeve.

Implant length: The length of the implant from

the shoulder to the apex.

The static guided implant system used in this

study (DIOnavi Digital Navigation Implant

system; DIOnavi) has a clearance of 100 microns,

sleeve length of 4mm, offset values 9 mm, 10.5

mm and 12 mm and implant length of 7 mm, 8.5

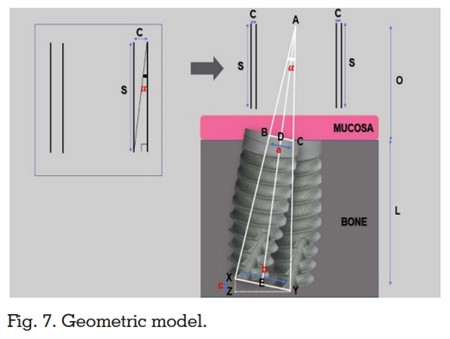

mm, 10 mm, 11.5 mm, and 13 mm. A geometric

model was prepared based on the above mentioned contributing factors to obtain formula

for calculating the error that can be introduced

in implant position (Fig. 7). For obtaining the

geometric formula, a perpendicular bisector

was dropped from point A to point E bisecting

such that ∠ADB=∠ADC=AEX=AEY=90

degrees. ABC and AXY are isosceles triangles.

By applying the principles of geometry, following

formulae were derived:

where C=Clearance, S=Sleeve length,

O=Offset, L=Implant length, Angular deviation

of implant axis, a=Linear deviation at implant

shoulder, b=Linear deviation at the implant

apex, c=Vertical deviation at the implant apex.

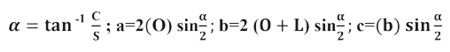

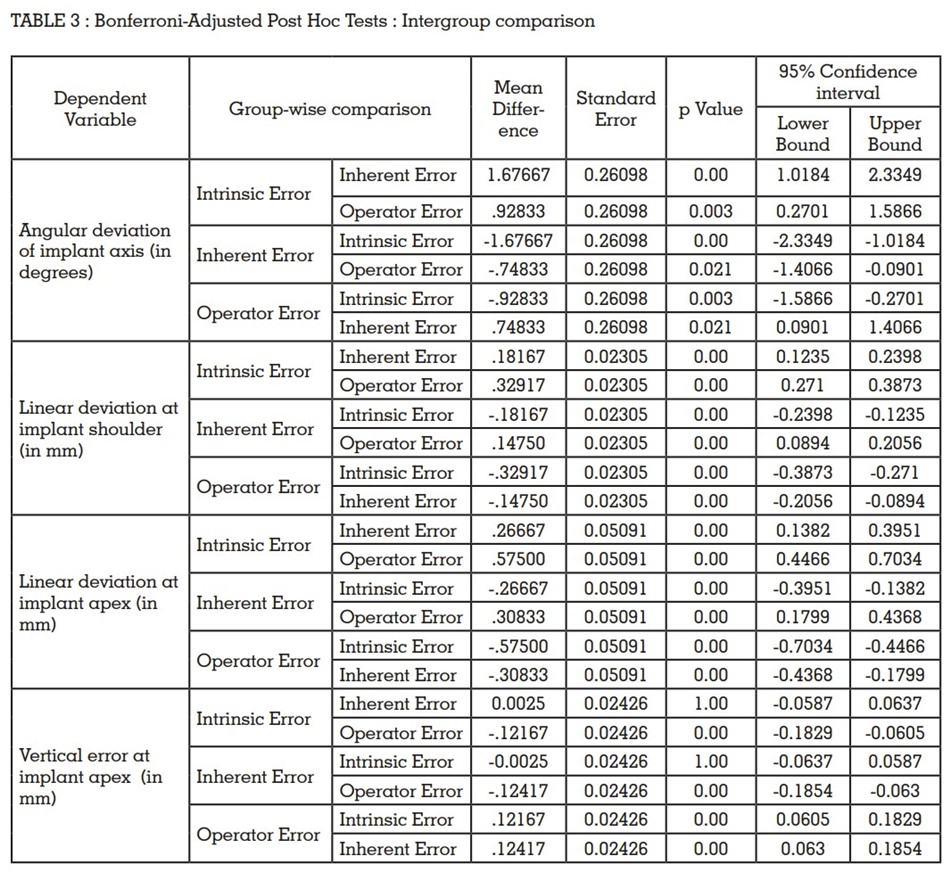

The data were entered into a spreadsheet

(Excel; Microsoft Corp) and subjected to

statistical analysis (One-Way ANOVA and

Bonferroni-Adjusted Post Hoc Tests for intergroup

comparison) using a statistical software program

(SPSS Statistics v17.0; SPSS Inc).

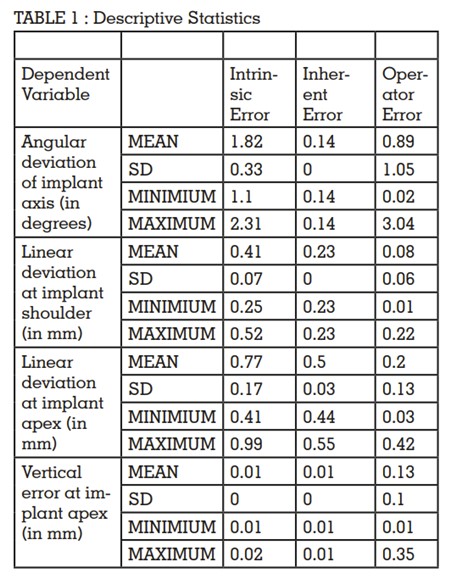

The mean, standard deviation, minimum and

maximum values for angular deviation, linear

deviation at shoulder and apex of implant and

vertical error observed at the apex of the implant

have been shown in angular deviation values

are shown in Table 1. The results for One-Way

ANOVA and Bonferroni-Adjusted Post Hoc Tests

for intergroup comparison have been shown in

table 2 and 3 respectively.

ItE was observed to be a major contributing

factor to the angular deviation of the implant

followed by OE. IhE contributed the least to

angular deviation (P value <0.05).

The major contributing factor for linear deviation

at shoulder of implant was found to be ItE followed by IhE. The effect of OE was found to be

the least at the shoulder of the implant (P value

<0.05).

Greater linear deviation was observed at the

apex as compared to the shoulder of the implant.

The major contributing factor for linear deviation

at apex of implant was found to be ItE followed

by IhE and OE (P value <0.05).

The major contributing factor for vertical error

observed at the apex of the implant was found

to be error introduced by the operator during

implant placement. The impact of ItE and IhE on

the vertical deviation of the implant at the apex

was found to be negligent (P value <0.05).

Further, no correlation could be established

between the location of implant (maxillary or mandibular arch and anterior or posterior

region) and proximity of implant to the fixation

screws with the various types of errors.

The current study calculated the influence

of various factors (ItE, IhE and OE) on

the final implant placement when using

stereolithographically manufactured fully limiting surgical guides. Based on the findings

of this study, the null hypothesis that no error

would be introduced in implant placement due

to ItE, IhE and OE, was rejected.

Intrinsic error can be introduced by variety of

factors such as errors introduced during data

acquisition, software handling, including data

loss during conversion from the Digital Imaging

and Communications in Medicine (DICOM) format to STL, during the 3D printing of the guide,

and from polymerization shrinkage of the resin

material.7,11-14 Weitz et al11 evaluated evaluate the

accuracy of a surgical template-aided implant

placement produced by rapid prototyping using

a DICOM dataset and reported deviations

between 2.0 and 3.5 mm. Stumpel12 and Chen

et al13 evaluated the errors in the manufacturing

of surgical guides by comparing production

processes of different manufacturing systems

when using the same DICOM file. They reported

that production processes of the different

manufacturers do influence the accuracy of

the produced surgical guides. Gjelvold et

al14 evaluated the deviation in final implant

position using surgical guides fabricated from 2

different desktop printers in a digital workflow

and reported accuracy levels varied with

different printers. The above-mentioned studies

have evaluated individual factors influencing

intrinsic error, but the overall contribution of

these factors on implant placement still remains

indeterminate. In the present study, ItE was

evaluated by superimposing the STL files of

the virtual design and the STL files obtained by

scanning the stereolithographic surgical guides

followed by using a geometric derivation to

calculate the influence of this error on implant

placement. This study reported a mean angular

deviation of 1.82 degrees (Range : 1.1-2.4

degrees) of the guide sleeve which could lead to

a 0.41mm linear deviation at shoulder of implant

and 0.77mm at apex, and 0.01mm vertical error

at apex of implant.

The virtual implant placement using a 3D CAD

model helped identify clearance, offset, sleeve

length, and implant length as the potential

sources of inherent errors while using fully

limiting static guide systems. A 3D geometric

CAD model software-based study format was

chosen over an in-vivo study design to evaluate

the contribution of these factors in implant

placement and to eliminate operator error. As shown in the geometric derivations, angular

deviation was found to be dependent on the

sleeve length and clearance. An increase in

sleeve length would decrease angular deviation

whereas an increase in clearance would

increase the angular deviation and vice versa.

The linear deviation at shoulder of the implant

was dependent on the offset and clearance

values. An increase in offset would amplify

the effect of angular deviation on the linear

deviation at shoulder of implant. The linear

deviation at the apex of the implant was found to

be influenced by the offset, implant length and

angular deviation values. The vertical error at

apex depended mainly on the linear deviation

at the apex of the implant and the angular

deviation values. The results of this geometric

model are in accordance with the results of Koop

et al,15 Choi et al,16 Cassetta et al,17-18 Van Assche

et al,19 Lee et al,20 and Schneider D et al. Koop

et al15 evaluated the degree of deviation that

can occur during the drilling procedure, and

reported that variations in the sleeve height,

offset and clearance of the surgical guide

influenced total error in implant placement. Choi

M et al16 also varied the clearance, offset and

channel length, and found that channel length

was the primary controlling factor in minimizing

deviated angulations. Cassetta M et al,17-18 Van

Assche et al,19 Lee DH et al,20 and Schneider D et

al21 evaluated the error that originated from the

clearance in the surgical guides and reported

that this factor significantly influenced implant

placement. The results of the aforementioned

studies are a cumulation of operator and

inherent error. Thus, the role of inherent error still

remained unclear.

The OE was calculated by superimposing the

pre-operative and post-operative CBCT by

utilising the metal sleeve of the surgical guide

as a reference following which the linear and

angular measurements were made. This was

done intentionally to nullify the impact of incorrect positioning of the surgical guide while

placing the implants. This helped identify the

influence of the operator on the final implant

position. A paucity of data was observed with

respect to evaluation of the role of operator in

introducing error during implant placement.

Various authors have conducted systematic

reviews to assess the overall error in implant

placement when using static guide systems.

Schneider et al9

conducted a systematic review

of 10 articles and their meta-regression analysis

revealed a total mean deviation of 1.07 mm at the

entry point and 1.63 mm at the apex. Van Assche

et al23 in their review reported a mean error of 0.99

mm (ranging from 0 to 6.5 mm) at the entry point

and 1.24 mm (ranging from 0 to 6.9 mm) at the

apex. The mean angular deviation reported was

3.81 degrees (ranging from 0 to 24.9 degrees).

In the current study the cumulative error values

of ItE, IhE and OE are less than the error values

in the aforementioned studies. A reason for this

disparity could be that this study has evaluated

3 different sources of error.

This study utilised a mucosa supported surgical

guide. Varied results might be observed with

tooth supported guides since tooth supported

guides have a reportedly better accuracy due to

their superior fit and stability.24 Also, this study

used only one static guided system. The results

may vary with different systems. Hence, similar

studies should be further conducted on different

systems to fully evaluate the sources and extent

of various errors.

The authors would like to acknowledge Dr

Navneet Kumar (Senior Manager, Production,

Planning and Clinical Support, DIO Navi Digital

Navigation Implant system, India) and Mr

Himanshu Bishwash for their help and technical

support.