Peri-implantitis is an inflammatory process which occurs around an osseointegrated implant, resulting in pocket formation and bone loss. Most implant system consist of two pieces; an implant fixture and an abutment, the microgap which exist between them is referred as implant-abutment interface. The aim of this study was to evaluate the adequacy of sealing materials on microleakage at implant-abutment interface.

Key words: Microleakage, Implant-abutment interface, periimplantitis

Peri-implantitis is an inflammatory process which

occurs around an osseointegrated implant, resulting in pocket formation and bone loss1

. Most

implant system consist of two pieces; an implant

fixture and an abutment, the microgap which exist

between them is referred as implant-abutment

interface2

. This gap at implant-abutment interface

offer shelter to the accumulated biofilm which

contain bacteria leading to bacterial colonization

and peri-implantitis3

.

Microleakage has been considered to occur in

both directions from an external source to the

inner area of an implant and vice versa. The gap

between the implant and abutment facilitates the

microleakage4

. During function, bending forces act

on the implant component which losses the screw

joint, thereby increasing the gap. It also produces

the pumping effect to transport the bacteria,

allowing for microleakage5. Various measures have been used to prevent microleakage at implant-abutment interface using sealing material, shape

memory alloy and different connection geometries4

.

The aim of this study was to evaluate the adequacy

of sealing materials on microleakage at implant-abutment interface.

Experimental Groups

In this study, 120 titanium dental implant, standard,

internal hexagon, 3.5mm diameter, and 10mm length were utilized to assess the adequacy of

different sealing materials at IAI (implant-abutment

interface). The samples were divided into three

groups containing forty samples of each group:

Group I: Titanium dental implant with internal

hexagon were connected with straight, titanium

abutment 3mm with a torque of 25Ncm according to

manufacturer instructions, without the application

of sealing material at IAI.

Group II: Titanium dental implant with internal

hexagon were connected with straight, titanium

abutment 3mm with a torque of 25Ncm according to manufacturer instructions with the application

of antimicrobial sealing gel (Gapseal) at IAI.

Group III: Titanium dental implant with internal

hexagon were connected with straight, titanium

abutment 3mm with a torque of 25Ncm according

to manufacturer instructions with the application

of O-ring at IAI.

Preparation of the samples

Under sterile conditions, dental implants and

abutments were removed from commercial

packaging. These samples were cultured for

another 24 hours in a sterile nutrient solution, to

ensure complete sterilization. The sample that

fulfilled the criteria was selected for the study.

Revival of staphylococcus aureus from

freeze-dried culture powder

Freeze-dried culture powder of staphylococcus

aureus (MTCC 3160) was revived by incubating the culture powder in nutrient broth for 24 hours

under a sterile environment. 50ml of this suspension

were transferred on Tryptic Soy Agar plate using a

sterile loop. The bacteria were streaked across the

plate from left to right and top to bottom and the

plates were incubated for 12 to 16 hours at 37°C to

obtain isolated colonies of staphylococcus aureus.

Preparation of inoculum

The cultures of Staphylococcus aureus (MTCC

3160) onto Tryptic Soy agar were used to prepare

a bacterial suspension of about 1 x 108 colony

forming units (CFU/ml) in nutrient broth by

adjusting turbidity to 0.5

Experimental procedure

The experimental procedure was carried out

under aseptic conditions. The working area was

disinfected with 70% ethanol before starting the

procedure. The aseptic conditions were maintained

by following routine measures such as using sterile

gloves, sterile equipment, eye protection, Bunsen

burner, and laminar flow cabinet. The implant

and abutment from each group were attached

and immersed into 3ml of bacterial suspension

inoculated with Staphylococcus aureus that covered

the IAI. These samples were further incubated at

37°C for 24 hours. Later, the assemblies were

removed from the bacterial suspension and the

external surface is decontaminated with a 2%

solution of sodium hypochlorite for 30 minutes.

The residual sodium hypochlorite was removed

with normal saline.

To check the adequacy of the external surface

decontamination strategy, the assemblies were additionally placed in sterile nutrient solution and

incubated for 24 hours at 37°C.

After decontamination, the implant and abutment

assemblies were disassembled and submerged

into sterile nutrient solution in the test tubes.

The test tubes were agitated so that nutrient

solution sufficiently contacts the inner surface of

the implant and abutment assemblies, allowing

the bacteria to flow into the solution. Nutrient

agar plates were divided into four quarters and

were inoculated with 100μl of nutrient solution

(containing staphylococcus aureus). The nutrient

agar plates were then incubated for 24 hours at

37°C.

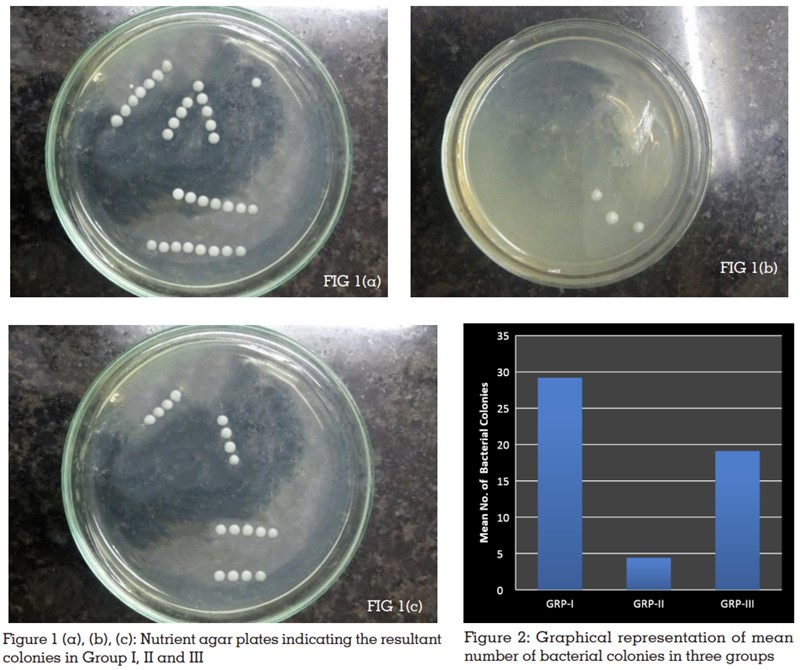

The resulting colonies were identified and

quantified (FIGURE 1).

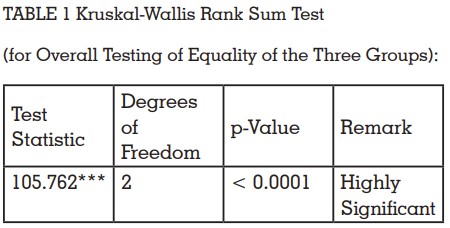

Statistical analysis was performed using

customized R programming software. The data

obtained was subjected to Kruskal Wallis analysis

of variance (Table 1). The level of significance was

set at p ≤ 0.05. Statistically, a significant difference

was found between the three groups (P-value

<0.001). The Mann-Whitney U-test was applied to

evaluate differences between the three groups with

respect to the mean number of bacterial colonies.

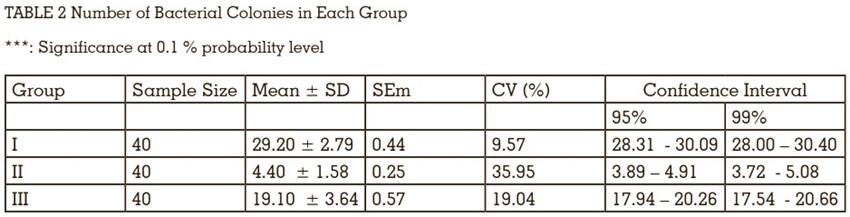

Microleakage occurs in all the groups with or

without sealing material. In group, I maximum

bacterial count was observed, ranged from 25 to

33 (mean, 29.20; standard deviation (SD) +- 2.79).

In group III average bacterial count ranged from

13 to 25 (mean 19.10; SD,+-3.64). However, group

II exhibit the maximum resistance to microleakage,

observing the least bacterial count, ranged from

2 to 6 (mean, 4.40; SD+-1.58) (TABLE 2).

There existed highly significant differences among

the three groups understudy for the average number

of bacterial colonies (FIGURE 2). Consequently, it

becomes imperative to make post-hoc comparisons among their performance, using the Mann-Whitney

U test. Member groups in all the three paired

comparisons showed highly significant differences

(each at 0.1 percent probability level) concerning

the mean number of bacterial colonies (TABLE

3).On average, the number of bacterial colonies

was the minimum (= 4.4) in Group-II, followed

by that (= 19.1) in Group-III and the maximum

(= 29.2) in Group-I.

The present study was conducted to assess the

adequacy of sealing material at the implant-abutment interface to prevent microleakage.

The results showed that bacterial infiltration

of staphylococcus aureus occurs in all three

groups, however, the least amount of bacterial

infiltration was observed with Gapseal followed

by O-ring. Furthermore, the study was conducted

under static conditions, which revealed that the

presence of sealing material help to reduce the

microleakage, but a reliable seal is not obtained

at the interface. The presence of gapseal helps to

reduce the leakage by its antimicrobial properties

or its sealing ability. Gapseal is a highly viscous

silicone material, which allows it efficiently seal

the interstitial spaces, maintaining a complete

seal. It also has hydrophobic properties, which

ensure high retention and prevent it from being

washed away6

. Several studies have shown the

same results7-9.

Paolantonia et al. found that filling the internal

cavity with 1% chlorhexidine gel; significantly

reduce bacterial colonization over a period of

6 months7

. The sealing ability of chlorhexidine

varnish and silicone sealant was tested by Duarte

et al. In vitro, both materials could prevent some

bacterial leakage for a period of 45 to 63 days8

.

Nayak et al. recommended the use of gapseal

to enhance the sealing capability, the viscous

nature of the gel allows it to flow easily throughout

the interfaces2

. Zarbakhsh et al. reported that

gapseal reduces the microgap and prevents the microleakage under cyclic loading9

.

In group III microleakage occurs because the

O-ring prevents the abutment from complete

seating, resulting in increased microleakage at the

implant-abutment interface. Furthermore, rubber

can also deteriorate over time, leading to increase

leakage. Without sealing material microleakage

occurs in group I, which was most likely owing to

the lack of complete wall adaptation between the

implant and abutment assembly2

.

Several investigations have revealed bacterial

leakage along with the implant-abutment interface

of systems with varied connection arrangements10.

Quirynen et al. found that microbe infiltration

occurs into the internal part of the implant which

could be a result of abutment installation or

unscrewing5

. Jansen et al. stated that microleakage

occurs at the implant-abutment interface, even if

the size of microgap was less than 10μm11.

The Rationale to use colonies of Staphylococcus

aureus for the present investigation was the

biological role that, this aerobic bacterium has,

during the initial phase of biofilm development

on the titanium implant surface. It is an initial

colonizer with a strong affinity to attach to other

pathogenic bacteria as well as to any type of

titanium surface12.

Cyclic loading of the implant may also contribute to

microleakage. One limitation of the present in vitro

study is that cyclic loading was not implemented

to mimic masticatory stress. Steinebrunner et al.

investigated bacterial leakage at the implant-abutment interface, following the use of dynamic

loading, which significantly improved in various

implant systems13. According to Nascimento et al.

human saliva can penetrate the implant-abutment

interface under loaded and unloaded conditions14.

Thus, it’s vital to substantiate or contrast the current

study findings with different loading conditions.

Considering the limits of the present in-vitro study

it was concluded that Gapseal was effective in

preventing microbial leakage at implant-abutment

interface followed by O- ring. Further evaluation

is needed about the longevity of the antibacterial

sealing gel.