Introduction: Glass ionomer luting cements (GIC)

and Resin modified glass ionomer luting cements

(RMGIC) are used to attach and seal fixed dental

prostheses to teeth. Despite of their anticariogenic

properties, there is still existence of caries. Studies

have shown incorporation of chlorhexidine (CHX)

can increase its antimicrobial action without

affecting their physical properties.

Objectives of the study: The objective was to

evaluate the effect of incorporation of CHX on

flexural and compressive strength of conventional

GIC and RMGIC. To compare the strength of both

the cements on incorporation of CHX.

Methodology: Forty bar shaped specimens and

cylindrical specimens of both the cements were

prepared for flexural strength and compressive

strength testing using stainless steel mold. CHX

powder was incorporated into experimental groups

of both luting cements in a concentration of 1%.

Specimens were stored in artificial saliva for 24

hours. Flexural strength and compressive strength

of the specimens was determined using universal

testing machine. Morphological evaluations for

fractured surfaces were done using scanning

electron microscopy. The data was statistically

analyzed using independent sample t-test.

Result: The results of the study showed that, addition

of 1% CHX decreased compressive and flexural

strength of both conventional GIC and RMGIC. On

addition of CHX RMGIC showed better compressive

and flexural strength compared to conventional GIC.

Conclusions: The Chlorhexidine (CHX) amount

should be kept below 1% for both the cements to

sustain their strength.

Key words: Glass Ionomer Luting Cement; Resin Modified Glass Ionomer Luting Cement; Chlorhexidine; Compressive Strength; Flexural Strength

Dental luting cements link fixed dental restorations

and tooth structure. This attachment may be

mechanical, chemical, or a combination of both

methods. In addition to providing a gap-free

interface, the luting cements should ideally also

help to prevent micro leakage and secondary

caries and decrease the failure rate of partial

fixed dental prostheses.1

The ability of glass

ionomer cement to release fluoride continuously

over an extended period of time, results in an

anticariogenic potential showing a reduction in

caries adjacent to the restoration.3

Recently, there has been considerable interest in

luting materials with adhesive capabilities and

therapeutic potential. Glass ionomer cements

(GIC) are acid–base cements which are used

widely in dentistry which have been used more

recently as bone cements.6

Conventional GICs are

complex materials, constituted by a calcium and

aluminium polyacrylate matrix with glass particles

embedded in it.7

Conventional glass ionomer

luting agents have fluoride ion release, physio-chemical bonding to tooth structure, and a low

coefficient of thermal expansion.8,9 Resin-modified

glass ionomer cements also release fluoride and

contain resin components for improved physical

and mechanical properties.10 Resin luting agents

are required for cementation of porcelain veneers,

all-ceramic crowns, and indirect composite or

ceramic restorations and are now available in

autopolymerization, light-polymerization, and

dual-polymerization formulations. Several attempts

in developing GIC with enhanced antibacterial

effects by addition of bactericides, such as,

chlorhexidine hydrochloride, cetyl pyridinium

chloride, cetrimide, and benzalkonium chloride

have been reported in the literature.11 Two groups

of bacteria are responsible for initiating caries:

Streptococcus mutans (SM) and Lactobacillius

casei (LB).12,13 Among the different antimicrobial

agents used to control dental microorganisms

the use of chlorhexidine (CHX) mouth rinses to control dental plaque and gingivitis has been

well established.14 Chlorhexidine has been

considered as one of the most effective and

safe substances.15 Therefore, to provide specific

and continuous antibacterial protection against

complex microorganisms residing between the

teeth and fixed restorations, incorporating CHX

may improve clinical success. The addition of small

concentrations (1%) of chlorhexidine increased

the antibacterial activity without compromising

the mechanical properties.18

The luting cements are subjected to compressive

and tensile stresses by masticatory forces.19

Luting cements must withstand masticatory and

parafunctional stresses for many years in a warm

and wet oral environment.20

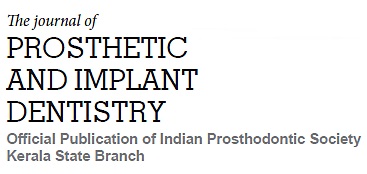

Two glass ionomer cements were employed in

this study, a conventional glass ionomer luting

cement (Fig. 1) which was grouped as A and a

resin-modified glass ionomer luting cement (Fig

2) which was grouped as B. For each cement

type twenty bar shaped specimens of dimension

25×2×2mm (according to ISO Standard-4049)6

were made to test the flexural strength (grouped as

Fs) and twenty cylindrical specimens of dimension

12×6mm (according to ANSI/ADA Specification no

66)19 were made for compressive strength testing

(grouped as Cs) using a brass mold of appropriate

dimension as shown in Fig 3 and Fig 4 respectively.

The molds were coated with petroleum jelly. Control

group contained twenty specimens for each type

of cement, which were prepared according to

recommended powder liquid ratio for testing

both flexural and compressive strength. Three

measuring spoons of powder and 3 drops of liquid

were necessary to fill the 12mm x 6mm matrix,

three measuring spoons of powder and 3 drops

of liquid were necessary to fill the 25×2×2mm

matrix. They were manipulated over a mixing

sheet using plastic spatula which were supplied

by the manufacturer. A plastic plate was placed below the trough; the mix was over packed into

the trough and tightly covered with plastic plate.

The experimental groups containing total of forty

specimens were prepared by adding 0.342 g of

CHX diacetate monohydrate (Fig 5), which is commercially available as a solid powder, to 30g

glass ionomer powder and for 11 gram of RM GIC

0.11g of CHX was incorporated. Within 60 seconds

after the end of mixing, the cements were packed

into the split molds and covered with the plastic

plates. One hour later, the specimens were removed from the mold and stored at room temperature in

artificial saliva (wet mouth – synthetic saliva with

pH of 6.43± 0.26 consisting of 0.8g NaCl, 2.4g KCl,

1.5g NaH2 PO4, 0.1g Na2S and 2 g CO[NH2]2)

for 24 hours.

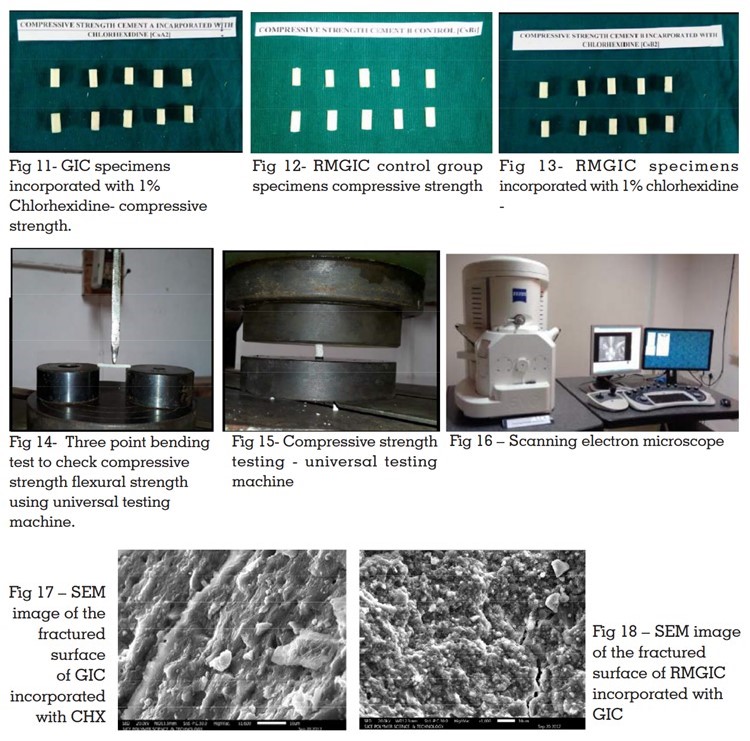

Flexural strength of the specimens was determined

using three point bending test in a universal testing

machine. A load was applied in the center of the

specimens at the crosshead speed of 0.5 mm/min.

The mounting apparatus was mounted parallel

with the supporting beams 20 mm apart (Fig 14).

The specimens were loaded until the first sound

of a crack was detected. The flexural strength

values of each specimen were calculated with the

following formula:

F=3PfL/2WH2

Where Pf - measured maximum load at the time

of specimen fracture,

L - distance between the supports on the tension

surface (20mm),

W - mean specimen width,

H - mean height of specimen between the tension

and compression surfaces.

Compressive strength of the samples was

determined using universal testing machine

under a crosshead speed of 0.5 mm/min until the

specimen fractures (Fig 15).

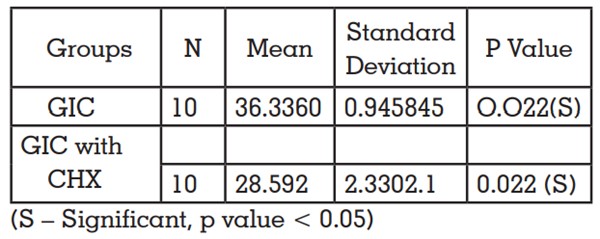

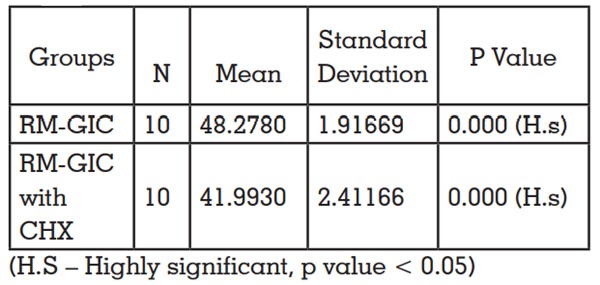

Table 1- Comparison of mean compressive strength

of GIC and GIC incorporated with CHX using

independent t test.

Table 2- Comparison of mean compressive strength

of RMGIC and RMGIC with incorporated CHX using

independent t test.

Table 3- Comparison of mean compressive strength of

GIC with incorporated CHX and RMGIC incorporated

with CHX using independent t test.

Results will be recorded in Megapascals.

C = F/πr2

Where F - measured maximum load at the time

of specimen fracture,

r - radius.

Morphological evaluation for fractured

experimental group surfaces was done using

scanning electron microscopy (Fig 16).

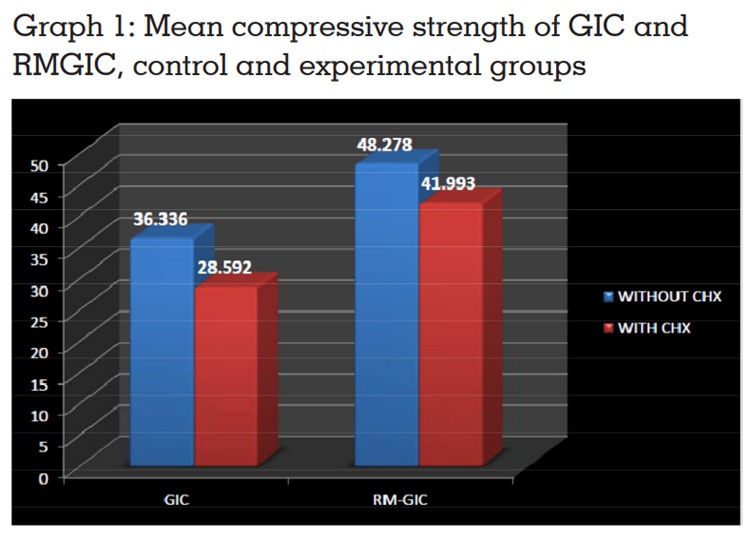

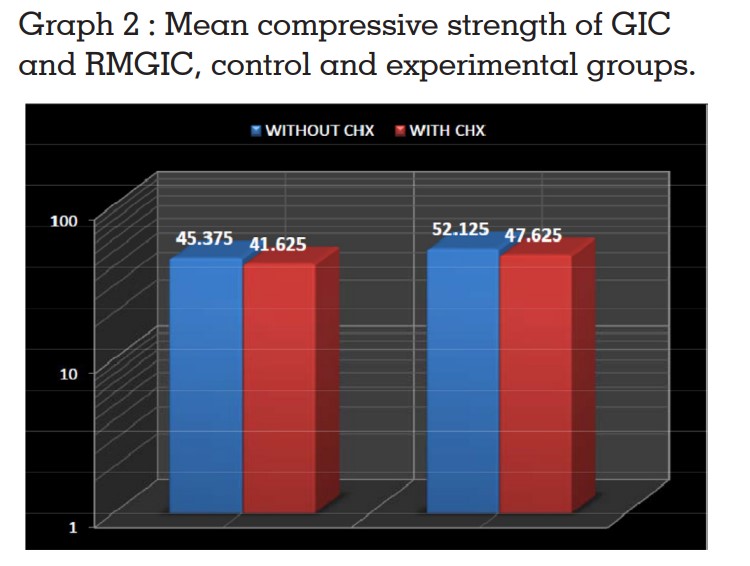

Compressive strength of GIC and GIC incorporated

with 1% CHX was compared, the result obtained

are shown in Table 1. On adding 1% CHX to GIC

resulted in significant decrease in compressive

strength (p<0.05). Compressive strength of

RMGIC and RMGIC incorporated with 1% CHX

was compared. Highest compressive strength

was shown by RMGIC but the strength values

decreased significantly by adding 1% CHX as seen

in Table 2. Compressive strength of RMGIC mixed

with 1% CHX was higher than GIC experimental

group according to independent t-test. Least

strength was shown by GIC mixed with 1% CHX

as shown in Table 3 and is represented in Graph 1.

The effect of incorporation of 1% CHX to

conventional GIC and RMGIC on flexural strength

was compared. In comparison with the control

adding 1% CHX for both GIC and RMGIC resulted in significantly decreased values when analyzed

with independent t test (p < 0.05).Flexural strength

of RMGIC with 1% CHX was higher than that of

GIC with 1% CHX. Highest flexural strength was

shown by RMGIC < RMGIC mixed with 1% CHX

< GIC < GIC mixed with 1% CHX when analyzed

with independent t test (p<0.05).

Morphological evaluation of fracture surfaces

of both the experimental groups were evaluated

by SEM study (Fig 17) shows the SEM image of

fracture surface of GIC with 1% CHX at X1600

magnification. Different sizes of glass particles

which were loosely bonded to the matrix were seen.

Fig 18 shows the SEM image of fracture surface

of RMGIC with 1% CHX at X1000 magnification.

The fracture surface of the RMGIC contained many

small glass particles dispersed in the polymer

matrix. Unlike GIC, the fracture surface of RMGIC

exhibited a more tightly integrated glass particle–

polymer matrix surface and less exposed glass

particles. In addition, large fractured fragments

of the resin constituent were observed in the RM

GICs, compared with the GICs.

Glass ionomer cements (GICs) were introduced in

dental practice in 1972 by Wilson, Kent. The powder

component contains aluminum-fluorosilicate glass that dissolves upon interaction with polyacrylic

acid in the liquid component. The reaction releases

calcium and aluminum ions that interact with the

carboxylic acid groups. Calcium ions present in

the hydroxyapatite of dental hard tissues, enamel

and dentin, react with the carboxylic acid of GICs,

creating a chemical bond between the cement

and the tooth structure.

GICs are widely used in dentistry for its advantages

of potential to inhibit caries because of fluoride

release, adhesion to tooth tissue, reduced marginal

leakage due to thermal changes in the oral

environment since coefficient of thermal expansion

of glass ionomer cement is similar to that of enamel

and dentin. Resin modified glass ionomer cements

(RMGICs) were introduced to provide a material

with improved mechanical properties and the

light cure facility.16

The most commonly used strength value to

characterize dental cements is compressive

strength. It is the ultimate strength to withstand

compression stress mainly for hard brittle

materials.12 However, such materials typically

fail in flexure rather than in compression, and

in recognition of this, there has been some work

in recent years to characterize them in terms of

biaxial flexure strength.22 In order to improve the antibacterial characteristics

of GIC, chlorhexidine (CHX) in the form of

chlorhexidine diacetate powder has been added

to it.22 CHX has also been seen to have long-term

antibacterial properties because of its unique

ability to bind to hydroxy apatite, whereby, a

gradual release creates a bacteriostatic milleu

over a prolonged period of time.4

Addition of CHX

in liquid form results in decreased properties due

to more rapid leaching of CHX in liquid form than

in powder form and CHX diacetate is preferable

to use, as it is a more stable material, not prone to

decomposition, can be easily blended with glass

ionomer powder.22 Therefore in the present study

CHX was added to CGIC in powder form.

In the present study specimens were stored for

a day because a minimum of 24 hr storage is

required for the maturation of GIC, where calcium

ions linked to carboxyl groups of polyacrylic acid

chains are replaced by aluminum ions, and also

according to a study done by Cattani-Lorente

MA et al10.

In the present study incorporation of 1% CHX for

both CGIC and RMGIC resulted in significant

decrease in compressive and flexural strength

properties. The microstructure of GICs is formed

as a result of the acid–base reaction between

the proton donating acidic liquid and proton

accepting basic powder resulting in filler glass

particles distributed within a salt-like hydrogel.25

The compressive strength of the cement arises

from the reinforcing glass filler particles, which

resists compressive forces on loading rather than

the weak matrix.25 In experimental groups RMGIC

had significantly higher values than CGIC, this is

consistent with the study done by Xie D et al9

and

Mallmann A et al.19 This is due to the inclusion of

resinous polymers that present higher mechanical

strength.

Limitations of the study include not considering

the change in temperature and pH which may

occur in oral cavity during consumption of various

beverages. The artificial saliva used did not consist of enzymes and plaque biofilm that is present in

a real life scenario. The result may not be same

to other commercially available GICs due to

difference in the filler size and can be evaluated

for change in strength by adding CHX for other

commercially available materials. Clinically it’s

tedious to keep weighing CHX and cement powder

for proper water powder ratio for each patient. This

can be solved by adding predetermined amount of

CHX to the whole bottle of cement, but the storage

stability of such cements is unknown.

Within the limitations of the study it could be concluded that-