3D printing is a revolutionary concept based on

additive process. It offers multifaceted applications

for dentistry in general and prosthodontics

in particular. A myriad of advantages like

reproducibility, accuracy, customisation and ability

to create complex parts with ease in less time have

provided improved patient treatment options and

compliance. This article presents an overview on

currently available technologies and their utilisation.

Abbreviations: CAD-computer aided designing,

FDM-fused deposition modelling, SLS-selective

laser sintering, SLA- standard triangular language,

PLA-polylactic acid.

Key words: 3D printing, CAD/CAM, additive manufacturing, bio printing, selective laser sintering, fused deposition modelling.

Charles Hull in 1983 printed the first 3D-object

using stereolithography.1

Digital dentistry was

pioneered by Francois Duret in 1970, with some

initial hiccups it took time to be integrated into

current practice.

Last few years have seen strikingly increased

application of 3D printing. The desired object/site

is scanned using an intraoral (IS) 3D scanner or

built using a CAD software. IS consists of a mini camera, integrated software and a computer.

Data is obtained as STF files (standard triangular

language)/STL (standard tessalation lan-guage).

This information is always broken down and stored

as triangles or tessellation. The tessellation is

the process of linking the surface with geometric

shapes to avoid overlaps and gaps. Stitching the

triangular files leads to a process of STL2

. These

STL files store the surface geometry of objects and

this information is encoded in ASCII (American

Standard Code For Information Interchange) or

Binary coding mostly which is used for small sizes3

.

This in-formation is used to print objects in layers

through various digital slicing and physically

re-produces layers with an automated process4

.

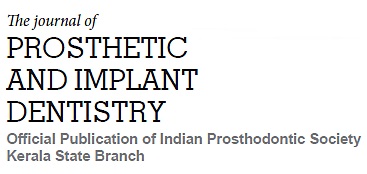

Additive Manufacturing is an additive process

referred to as rapid prototyping where a lot of

layers are added in contrast to traditional process

like subtractive manufacturing5

.

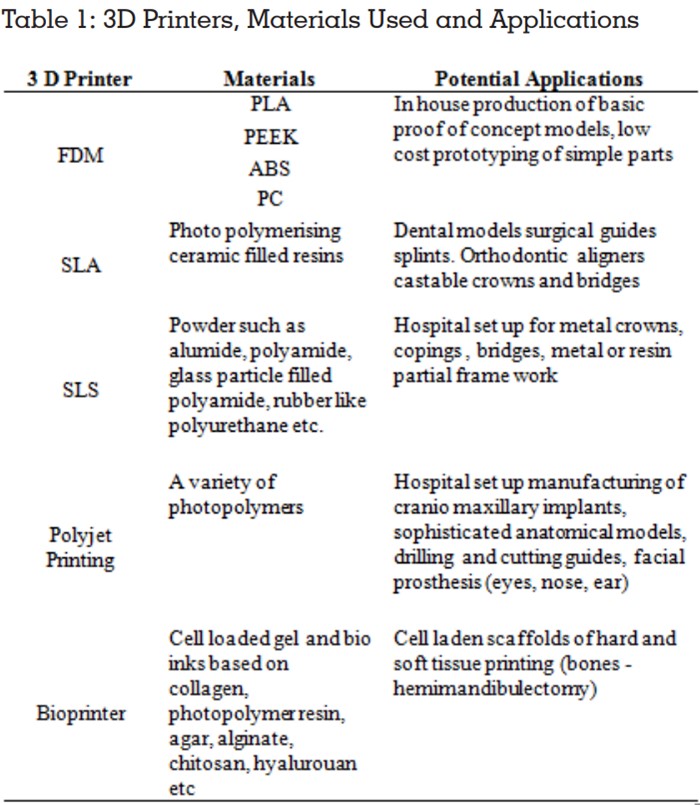

The most widely used additive methods include

fused deposition modelling (FDM), Stereo

lithography (SLA), Selective laser printing (SLS),

Polyjet Printing and Bioprinting6

, Direct metal laser

sintering. A variety of materials can be used which

include plastics, ceramics, resins and metals

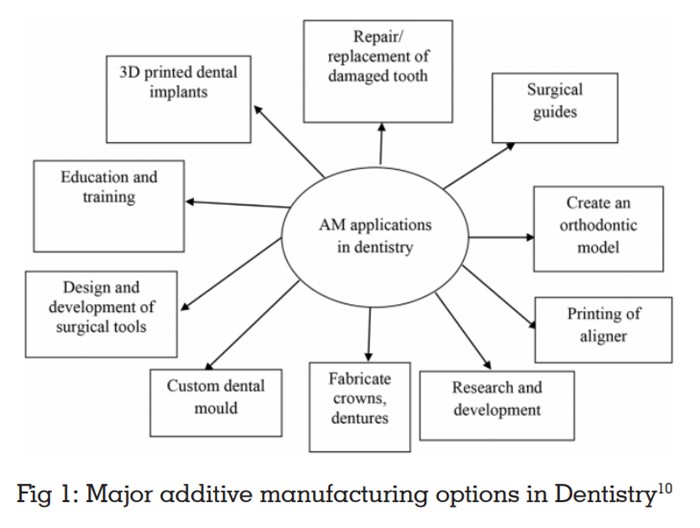

Developed by Scott Crump 1988, melted material

generally thermoplastic polymers such as poly

lactic acid (PLA) polycarbonate, polyether ether ketone (PEEK) is extruded through a nozzle to

print layer by layer. Print head has multi nozzle

and extrudes different types of material at the

same time7

. It is the printer of choice for in-house

production of 3D models8

. It is a flexible method

however its use is limited to temporary crown and

bridges manufacturing. Limitations include limited

colour selection, moderate printing resolution, and

complete removal of support material, surface

quality and time efficiency.

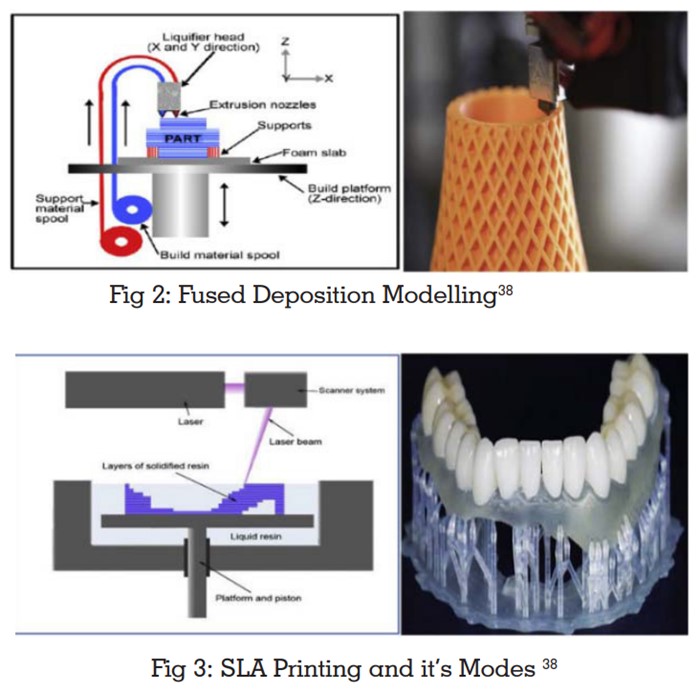

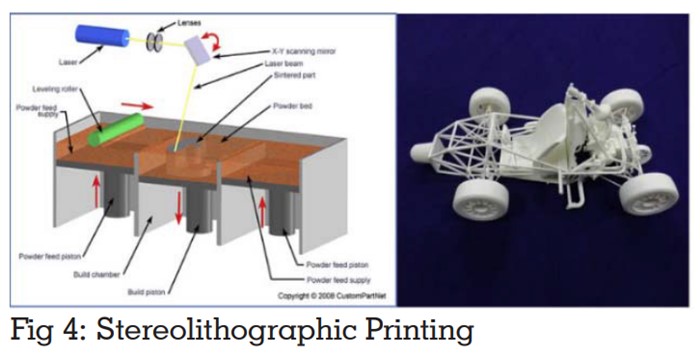

Both use laser to scan and build object layer by

layer but in selective laser sintering powder-based

material is used for printing.

SLA uses photo polymerisation - a process by which

the UV laser beam causes chain of molecules to

link together and form polymers.9

Products are built

with application of UV laser inside a vat of resin.10

SLA is used for printing from CT (DICOM data).

Advantages include good printing resolution as

compared to FDM; support material removal is

less too hence less wastage.

SLA is used to print surgical guides, aligners,

dental models and crowns, RPD’s, fabrication of

implant surgical guides.

SLS prints FDP’S, metal crowns and RPD’S. They

can replicate intricate geometries and provide

biodegradable scaffold for tissue engineering.

Printers with highest resolution. 3D model is

created one layer at a time by the printer head

getting layers of liquid photopolymer acrylic plastic

build tray followed by UV light curing11. It uses

widest choice of printing materials with varieties

in density, hardness, flexibility and porosity.

Resolution is as fine as 25-80 microns, faster

printing and replication of complex geometries.

Disadvantage includes post print model processing

such as intensive washing and removal of support

material.12

Applications include planning patient specific

3D models with complicated geometries, surgical

stents and guides, phantoms for orthopaedic

and cardiac surgeries, scaffolds for tissue

engineering.13, 14, 15

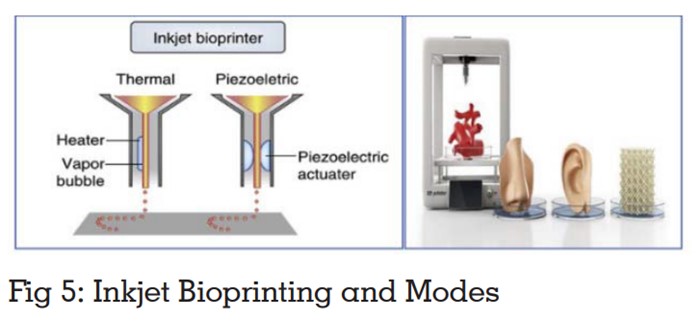

Uses photo polymerising materials stimulating natural cells such as chitosan, agar, alginate to

print hard and soft tissue scaffolds. Bio printing

uses cell ink based bio printers or spheroid or

micro tissue based systems have been developed

to generate artificial tissues, complex 3D in vitro

models.16,17 With that the additive manufacturing

has given a new face to discipline of stem

cell therapeutics with the flexibility of printing

cells into desired 3D complex, employing it for

transplantation and regeneration.18 3D printing

has found its applications in generating optimal

values of human bone and skin grafts in vitro.19

This has immense potential to replace the current

strategies of procuring auto grafts which is

associated with donor site morbidity and loss of

structure.20

This technology is used to produce metal parts with

high accuracy and better mechanical strength. In

this technology metal material is added layer by

layer and a laser beam is used to fuse metal at a

point.21,22 This uses titanium, cobalt, aluminium,

bronze alloy, steel. Approximate accuracy is 25-

35µm.

3D models are fabricated by adding layers of the

defined sheet of materials. A laser is used to cut

sheet as per the required cross section. Adhesives

are used to combine the layers and generated by repeating the steps.23,24

Powerful electron beam is used to build product

layer by layer by using a metal powder by

command of the CAD model with exact geometry.

Under a vacuum the raw material is stored and

fused by an electron beam.25, 26 Vacuum eliminates

impurities.

A literature search using search engines such as

Google scholar and Pubmed with keywords was

done, all articles from 2016 to 2020 printed in

English, inclusive of case reports, in vitro studies

and systematic reviews were considered.

Minev R, Minev E, 201627 stated that shrinkage

of 3D printed models is an unavoidable problem

during the printing process and it affects printing

accuracy of most 3D printers. FDM shrinkage

occurs due to thermal contraction when melted

filaments solidify. In SLA and multijet shrinkage

occurs due to polymerisation. Hambali RH, Cheong

KM, Azizan N, 201728 concluded that FDM has

bad surface quality due to staircase effect of

manufacturing using material extruding through

a nozzle. This was improved by approximately

97.2% via immersion in acetone solution for 300

seconds. This chemical treatment is one of the most

economical and fast methods to enhance surface quality of additive manufacturing parts for future

manufacturing industry. Raymond E Rebong et

al 201829 assessed the dimensional accuracy of

3D models with each other and compared with

traditional plaster casts. They concluded amongst

FDM, SLA, and Polyjet printing, the FDM had

fewest dimensional measurement differences as

compared to plaster mode.

Daniel Khorsandi et al 201830

Compared SLA and FDM methods of rapid

prototyping. They stated that SLA offers greater

efficiency, high level of accuracy. Layer thickness

of two different techniques FDM 0.5-0.127mm as

compared to SLA 0.05-0. 015mm. Both however

make rough patterns that need to be polished

to limit bacterial retention. Ucar et al, 201831

published an in vitro study to show that the

ceramics manufactured by stereolithography

show comparable mechanical properties to

milled ceramics. However, manufacturing process

and strength, fracture toughness are areas that require further research. To improve the properties

of ceramics so produced, porosity should be

eradicated resulting in denser more compact

mixture. Kim et al, 201832 proposed a new digital

prosthesis using an FDM printer to make a flask

for making a complete denture. This took 7 hours

to complete and showed satisfactory results in

terms of completeness of complete denture.

Using a universal development system software,

denture design STL and a denture flask STL were

superimposed, and the denture region was set as

an empty space. Conventional artificial teeth were

inserted into the 3D manufactured flask, resin

packing, finishing and polishing was done using

conventional method of fabrication of complete

denture. Fusong Yuan, Yao Sun, Lei Zhang, 201933

implant guide CAD and FDM 3D printing were used

to achieve a chair- side high efficiency design for

production of implant guides. Visual inspection

revealed that the positioning of 30 implant guides

was successful and retention was satisfactory. A

comparison of 3D data of printed implant guide

and CAD guide demonstrated a morphological

error of 0.5999 plus minus 0.146. Making FDM and

CAD time saving, efficient chair side methods. Lee

D et al, 202034 stated digital light processing 3D

printers (DLP) produce shrinkage depending on

the material and polymerisation method. Owing to

material characteristics the FDM accuracy of full

arch dental models is supposed to be higher than

that of the DLP however due to surface roughness

of the FDM method the crown preparation die for

dental prosthesis is not accurate. Therefore, a

new hybrid dental model that combines the FDM

for full arch and DLP for specific die is proposed.

Yoshiki Ishida et al, 202035 Compared the accuracy

of cylindrical patterns fabricated with consumer

FDM 3D printers with consumer SLA 3D Printers.

After the patency of FDM device expired, several

types of small consumer 3D printers were

introduced for personal use. The accuracy of

these less priced printers was compared with

dental FDM 3D and SLA 3D printers. The consumer

printers had worse accuracy than dental printers. An enlargement adjustment of 1-3% along the

horizontal axis was necessary to realise the set

design. In terms of surface roughness consumer

SLA produced smooth patterns. Hence, they

concluded that consumer printers have potential

to be used in dental applications.

Not only for manufacturing 3D has led to an

exemplary shift in training by providing idealistic

plastic typodonts to more real-life 3D printed

models that are based on data obtained by

intraoral scan of patients36. Polyjet printing has

successfully been used to create models in different

levels of hardness, replicating that of healthy

enamel, dentin and caries so that the trainee

experience proprioception of working on real

tooth37. 3D manufacturing undoubtedly offers a

promising future due to its multiple applications

and accurate detail reproduction however at the

same time it involves high investment cost. One of

its largest limitation is the quality. Due to the way

successive layers are deposited on top of each

other an inherent weakness is literally build into the

design. Finishing of final product is time consuming

and requires skill. Depending on the material

it may need additional treatment to reach full

strength. For example, zirconia blocks used require

further sintering to reach high strength. SLA can

be done only by using photopolymerising resins.

These are messy and can cause inflammation

and irritation on inhalation. Also, resins cannot

be heat sterilised.

3D printing has the potential of revolutionising

dentistry in general and Prosthodontics in

particular. Although the initial investment is high

and it requires training in usage, it helps to reduce the time for actual patient care. In today’s

scenario of emerging infective pandemics minimal

exposure to the clinician, technician and patient

can be offered. It can allow patient care from any

part of the world by exchange of information. It

has a great potential in research and treatment

modalities. Because the print object is produced according to the image of the patient, the print

can be tailored to optimally fit the condition of the

patient. The problem that requires further research

is the limitation of available material assortment

in particular when moving beyond the canonical

polymers as well as improvement of printing speed

and post processing requires.

Although it is not a replacement for conventional

treatment methods but its scope to improve and

develop is what the future of dentistry holds.

Source of support:

None.

Conflicts of interest:

The authors declare no

conflicts of interest.