Single complete dentures pose a great challenge to clinician. Chances of denture fracture are more when natural teeth are present in opposing arch. Heat cure acrylic resin cannot resist the heavy occlusal loads alone and it leads to denture fracture. This problem can be solved by use of innovative materials and appropriate techniques. Metal mesh reinforcement in denture provides satisfactory and economic solution for such cases. This case report describes a procedure of fabrication of metal mesh reinforced single maxillary denture, which is easy to fabricate and better in resisting masticatory loads of natural mandibular teeth.

Key words: Single denture, Metal mesh, Denture fracture.

The conventional acrylic resin denture fracture

is a challenging condition to prosthodontists.

Most common fractures are midline denture

fractures as reported in a recent dental survey.

Midline denture fractures 46.87% were seen in

maxillary complete dentures and 61% were seen

in mandibular dentures.1

The incidence of midline fractures increases in case of single maxillary

dentures opposing natural mandibular teeth.2

There are several factors contributing for denture

fracture including flexural fatigue resulting from

cyclic deformation and factors which alter the stress

distribution of the base.3,4 To avoid such fractures,

advancement in materials and techniques is prime

requirement. Use of metal reinforced denture

base,5

acrylic resin base reinforced with wire

netting, carbon fibre, E glass fibre reinforced

PMMA,6,7 lucitone 199, Trevalon high, Paladon

ultra and visible light polymerized resin8

are

different methods of increasing denture fracture

resistance and decreasing chances of failure. Out

of all these methods, metal mesh reinforcement

is an economic and less time-consuming method,

which significantly increases the denture strength.9

This case report describes a case of single

maxillary denture fabrication reinforced by use

of commercially available preformed metal mesh.

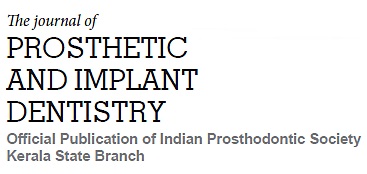

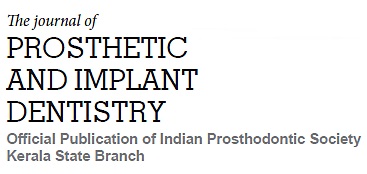

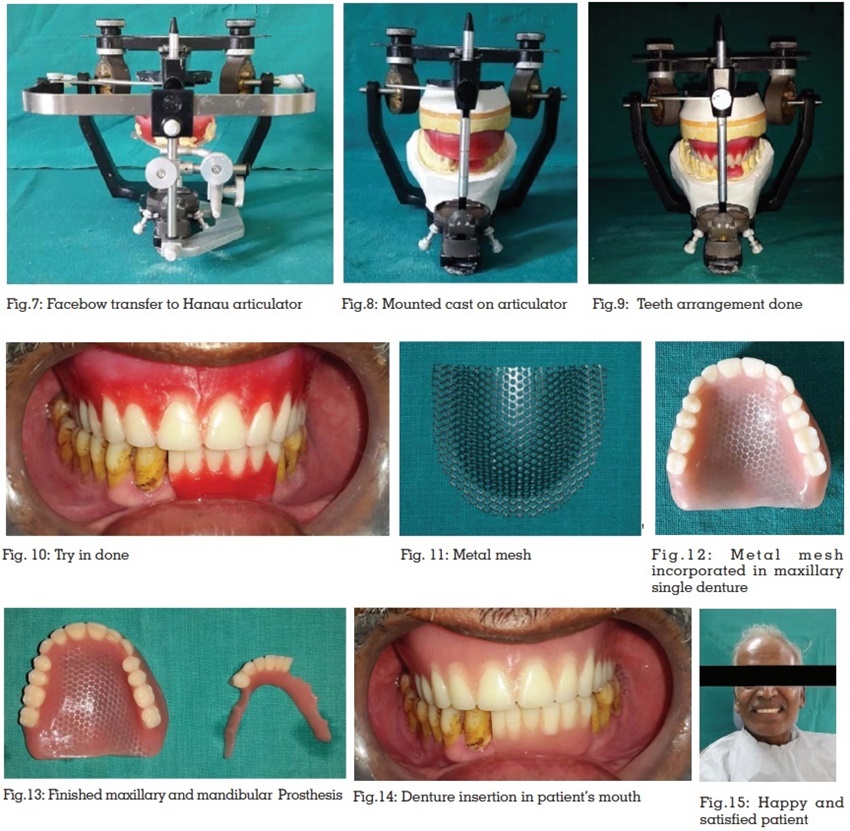

A 57-year-old male patient reported to Department of Prosthodontics and Crown & Bridge, with the chief complaint of difficulty in chewing due to missing upper and lower teeth. Patient had no significant medical history. Intraoral examination revealed completely edentulous maxillary arch (Fig.1) and kennedy’s class IV partially edentulous mandibular arch (Fig.2). Patient was explained about different treatment options-

Due to financial reasons, Patient was not willing to

go for implants and cast metal maxillary denture.

Metal mesh reinforced maxillary denture with

mandibular removable partial denture was

selected by patient. It was an economic option

with the benefit of increasing strength and fracture

resistance of denture.

Denture fracture results from two different types of

forces, namely impact and flexural fatigue. Impact

fracture occurs due to sudden blow to the denture

or accidental dropping of denture from hands or

mouth. Flexural fatigue occurs due to repeated

stress of lower dimension constantly, which

results in micro cracks formation in denture base.

Conventional denture base material Poly methyl

methacrylate (PMMA) shows poor mechanical

properties when put in an environment of heavy

occlusal loading and tends to fracture.10 Repeated

denture fracture is a problem for both patient and

clinician.11

Metal strengthener has a beneficial effect

on the fracture resistance of the polymethyl

methacrylate.12 Metal base and metal mesh

reinforcement increases the strength of denture

and reduces the micro crack propagation. Metal

mesh is commercially available in both stainless steel and gold plated metal. They have a thickness

of 0.4mm and their mesh design helps to produce

a good resin bond. Metal mesh does not increase

the denture weight and decreases the chances of

fracture.13,14 Metal mesh is also economic to patient.

Stock perforated trays, which are used for making

alginate impression can be cut and modified to

be inserted in denture. Modified portion of tray is

used for reinforcing the denture.15

Using metal mesh has few disadvantages. It

looks unaesthetic if it appears on labial portion of

denture when patient smiles. It is prone to corrosion

and has poor adhesion to acrylic denture base.

In some cases patient may be allergic to metal

contact. Some authors have proposed a technique

of masking colour of metal mesh using self cure

acrylic resin to avoid unaesthetic display of metal.16

Advancement in materials and techniques is

required to completely fulfill the requirements

of patient and clinician. Implant supported

overdentures are newer treatment approach for

single dentures.17 Due to financial reasons, not

all patients can afford implant treatment. Metal

mesh reinforcement is an economic and promising

solution for such cases.

It is a challenge for prosthodontists to provide

successful treatment for patients presenting one

completely edentulous arch opposing natural

teeth in other arch. Such condition places more

amount of force on single denture. Metal mesh

reinforced dentures offer better strength and

fracture resistance. This is a viable treatment

option for all patients who suffer from repeated

denture fractures due to heavy occlusal loading.