Acrylic resin dentures are susceptible to fracture after clinical use, which is a problem of concern in prosthodontics. The purpose of this study is to evaluate the effect of Microcrystalline cellulose (MCC) on the flexural strength of heat cure polymethyl methacrylate (PMMA) resin. Thirty rectangular strip specimens, ten of each group, of heat-processed denture base resin were prepared – control (n=10), heat-cured PMMA strips with 5wt% MCC (n=10), heat-cured PMMA strips with 10wt% MCC (n=10). Flexural strength was measured using the universal testing machine and the readings were subjected to one-way ANOVA and Post-Hoc Tukey HSD test. The results showed that the mean flexural strength of control, 5wt% MCC, 10wt% MCC groups were 40.52, 57.41, 49.98 MPa respectively. The 5wt % MCC showed better flexural strength than other groups and the results were statistically significant too.

Key words: Cellulose crystals, Microcrystalline cellulose, MCC, Flexural strength, Polymethylmethacrylate, PMMA

Polymethylmethacrylate (PMMA) has been the material of choice for conventional dentures for the past ten decades. The advantages of this material include the ease in processing and equipment use, cost-effectiveness,and its ability to mimic the colour and appearance of oral tissues1. With use, the denture base is subjected to many different influences such as biting forces, thermal changes, exposure to saliva, food, and water, and mechanical blows, which may result in denture failure and/or fracture. Despite its long history of clinical success, PMMA has a number of drawbacks such as poor flexural properties and low tensile and bending strengths,making it highly prone to fracture, the most common reason for clinical failure2. A number of laboratory studies testing denture base reinforcement have reported an improvement in its strength; however, none have been applied clinically. Most of these reinforcements have not been applied due to their high cost, the need for specialized processing, or increased laboratory time due to the complex procedures. Another reason is the difficulty in stabilizing the material used for reinforcement in a suitable position during the acrylic resin processing. Natural fibres as reinforcements have in the recent past attracted more attention due to their biodegradable and biocompatible properties3. They are from renewable resources, considered free of biohazards, and more costeffective when compared to synthetic fibres. Microcrystalline cellulose (MCC) form can be considered as a viable alternative to existing commercially available synthetic fibre-reinforced denture base resins. MCC is a biodegradable, purified, white, odourless, fine, non-fibrous, and partially depolymerized crystalline powder, usually isolated from cellulose through the hydrolysis process4. The null hypothesis of this study was that there is no difference between the flexural properties of MCC-reinforced PMMA denture base resin when compared to conventional PMMA.

The aim of the study was to evaluate the effect of cellulose microcrystals in two different concentrations on the flexural strength of heat cure PMMA.

The study was carried out in the department of prosthodontics in collaboration with Kalasalingam academy of higher education, to evaluate mechanical properties of denture base resins.

Group 1 (n=10): Heat cured PMMA

Group 2 (n=10): Heat cured PMMA with 5wt% MCC

Group 3 (n=10): Heat cured PMMA with 10wt% MCC

Three groups of ten specimens each of heat cure PMMA acrylic denture base resins were processed into rectangular plates in accordance with ISO 20795-1 (64mm x 10mm x 3.3mm). The specimens were divided into three groups: control, 5wt% MCC, and 10wt% MCC respectively. The control group consists of 10 specimens of heat polymerized denture base resin (DPI, Dental Products of India, Mumbai). Group 2 consists of 10 specimens of heat polymerized denture base resin containing 5wt% MCC by weight. Group 3 consists of 10 specimens of heat polymerized denture base resin containing 10wt% MCC by weight. The microcrystalline cellulose with a particle size of 50µm was purchased from Sigma-Aldrich Merck India. This was added to polymer powder by weight in 5wt% and 10wt% respectively and mixed well before adding monomer to the mixture. Powder liquid ratio was calculated based on manufacturer instructions.

Using the metal die of dimensions 64mm x 10mm x 3.3mm, 30 wax patterns were fabricated and subjected to conventional flasking procedures. Then heat polymerized denture base resin (DPI) was mixed and packed, as per the requirements of the three different groups, in the dough stage. This is followed by bench curing and processed according to the manufacturer’s instructions and specimens are recovered. After processing, the acrylic specimens were finished and polished to specific dimensions of 64 ± 0.001 mm in length, 10 ± 0.01 mm in width, and 3.3 ± 0.01 mm in thickness

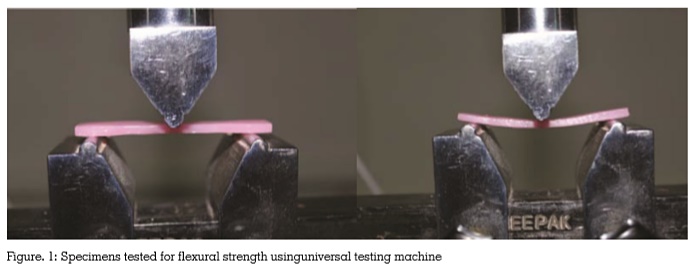

Measurement of flexural strength of samples was done using a three-point bend test per ISO 207951 guidelines for denture base polymers. Each sample was placed on circular support beams with a span length of 50mm. A load of 100 N was applied with a universal testing machine at the centre of the sample at a crosshead speed of 5mm/ min until fracture (Fig.1). The moment of fracture was designated as the moment the applied load dropped to zero. The data was tabulated and the results were statistically analysed. One-way ANOVA was done for the test of significance and Post-Hoc Tukey HSD for intergroup comparison of flexural strength of all three groups.

There was a statistically significant difference between the three groups tested for flexural strength with and without microcrystalline cellulose reinforcements. So, the null hypothesis was rejected.

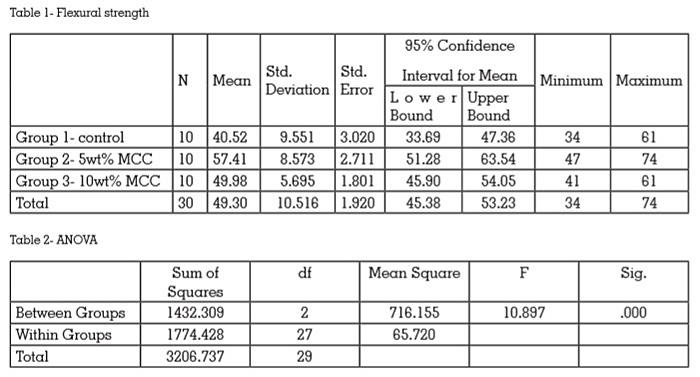

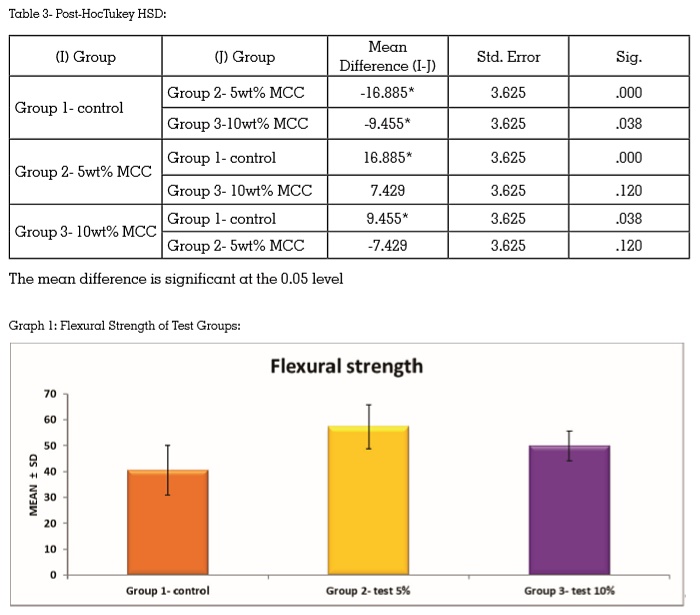

Tables 1 shows the mean and standard deviation values for the flexural strength of control and test groups. The collected data for flexural strength were analysed using one-way ANOVA and PostHoc Tukey HSD test and the values are tabulated in table 2 and table 3.

Table 1 shows the highest mean flexural strength value for Group 2 at 57.41 Mpa followed by Group 3 at 49.30 Mpa and the control group at 40.52 Mpa with a 95% confidence interval. Table 2 explains the sum of squares, the difference and the mean square values between and within groups and the values are highly significant.

Table 3 shows intergroup comparison of mean flexural strength using Post-Hoc Tukey HSD test and the highest mean difference was found between group 2 (5wt% MCC) and group 1 which was 16.885 MPa and the lowest was between group 2 (5wt% MCC) and group 3 (10wt% MCC) which was 7.429 MPa. All the mean values were statistically significant with P = 0.05. Statistically significant differences were found between Group 1 (Control), Group 2 (5wt% MCC), and Group 3 (10wt% MCC).

Graph 1 shows the mean flexural strength of all three groups. Group 2 shows the highest mean flexural strength and the lowest was group 1.

The search for increasing the strength of PMMA resin has led to the incorporation of fillers in it and newer additives like Microcrystalline cellulose (MCC) can also be used5. MCC can be obtained by partially hydrolysing cellulose using various acid, enzymes or microorganisms to remove amorphous regions resulting in its synthesis6. MCC is produced from various natural plant sources such as kenaf fibres, sawdust, rice straw, OPEFB, groundnut shells, sisal fibres, or cotton rags7. Cellulose is being used in the food industry, cosmetics, and pharmaceutical industries as well as in polymer composites as a reinforcing material8.

In previous literatures materials such as Glass fibres, Silanized glass fibres, Aramid, Nylon, Polyethylene, Polypropylene, Silanated Polypropylene, Oil Palm Empty Fruit Bunch (OPEFB), vegetable fibre (Ramie fibre), Alumina9, Zirconia, Silver, Titanium10, Nano-Gold, Platinum (Pt), Palladium (Pd), Hydroxyapatite, Silicon dioxide, Mica, Nano-Carbon and Nano-Diamond are used as fillers in dentures base resins11.

There is not much evidence regarding the use of MCC as fillers in denture base resins and their effect on various physical properties such as flexural strength, impact strength, and tensile strength12.

Hence in the current study different concentrations of 5wt% and 10wt% MCC as filler particles in Polymethyl methacrylate denture base resin and its effect on the flexural strength was tested.

MCC is introduced as fillers to overcome the drawbacks in the use of fibres as additives such as lack of bonding between fibre and polymer, exposure of fibres from margins12, and displacement of fibres while processing13.

Amira Ali Abdel et al14 reported the use of MCC obtained from Oil Palm Empty Fruit Bunch in concentrations of 2% and 5% as fillers in a previous study. From the study, he concluded that 5% MCC as fillers improved flexural strength of PMMA denture base resin. This study was in accordance with the results of our present study in which the 5wt% MCC showed better flexural strength when compared to 10wt% MCC. The MCC for this study was obtained by procuring high quality commercially available MCC from SigmaAldrich Merck India rather than manufacturing MCC as done by Amira Ali Abdel et al which is cumbersome.

In our present study, the Flexural strength of 10wt% MCC was less when compared to the 5wt% MCC group and the flexural strength didn’t improve with the increase in the concentration of filler particle. This is because when the flexural load was applied the increase in crystal content in the polymer matrix favoured the crack propagation as the distance between the adjacent crystals are too less. On the contrary in the case of the 5wt% MCC group the crystals are uniformly distributed and the distance between the adjacent crystals are more when compared with 10wt% MCC groups. So, the crack propagation is prevented to a certain extent in the case of the 5wt% MCC group. This is one of the reasons for the increased flexural strength values in the 5wt% MCC group.

And in our current study, the commercially available MCC was used and this can be easily mixed with polymer while processing denture base specimens. So, the process hydrolysis for the synthesis of microcrystalline cellulose can be avoided, time-saving and cost-effective comparing with Hi-impact denture base resins.

Further studies are required on other mechanical properties such as impact, tensile, compressive strengths, biocompatibility, and colour stability. In vivo studies are also required to evaluate the use of Microcrystalline cellulose (MCC) as filler in the PMMA denture base.

Within the limitations of this study the following conclusions are drawn: