Impression making is considered to be an important step in the fabrication of any fixed or removable prosthesis. However certain pathologic conditions such as Oral submucous fibrosis associated with reduced mouth opening critically hamper the impression making procedure. Proper orientation of impression tray in such patients becomes extremely difficult due to reduced resiliency of tissues and obliteration of vestibular spaces. The problems encountered in fabrication of complete denture for these patients especially during impression making are overcome by the use of sectional trays. This article focuses on use of sectional trays during preliminary and final impression making procedure for an edentulous patient with oral submucous fibrosis.

Restricted mouth opening impose a great challenge

to the dentist in performing any intraoral procedure.

This is commonly associated with conditions like

orofacial cancer surgeries, scleroderma, traumatic

injuries, temporomandibular joint disorders, oral

submucous fibrosis etc… Oral submucous fibrosis

is one of most common pathology associated with reduced mouth opening. Oral submucous

fibrosis (OSMF) is defined as a chronic disease

of the oral mucosa characterized by inflammation

and progressive fibrosis of the lamina propria

and deeper connective tissue layers. A number

of factors trigger the disease process by causing

juxta epithelial inflammatory reaction in the

oral mucosa. Suggested contributory factors

include areca nut chewing, ingestion of chillies,

nutritional deficiencies, genetic and immunologic

processes and other factors. OSMF is a potential

premalignant condition with an incidence of oral

cancer in 3-7.6% cases.1 The presenting symptoms

of OSMF are burning pain, progressive inability to

open the mouth with difficulty in mastication and

swallowing. It is most common between 20 and 40

years of age with a female:male ratio of 3:11. This

condition is prevalent among geriatric patients with

partial or complete edentulism. Restoring function

becomes a challenge to the prosthodontist due to

patient’s clinical presentation.

Several methods have been described for use

when a standard impression tray becomes difficult

to be inserted or removed from the mouth. During

impression making, modification of standard

impression procedure is required to accomplish the fundamental step in fabrication of successful

denture. Use of sectional trays can overcome the

problem of reduced access to the oral cavity during

impression making.

This clinical report describes the use of sectional

trays for preliminary and final impression for the

patient with reduced mouth opening due to Oral

submucous fibrosis.

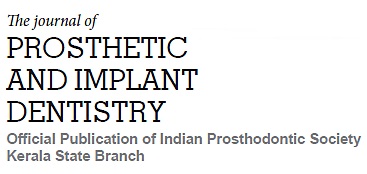

A 65 year old female patient (fig: 1a & 1b)

treated with intralesional therapy for chronic oral

submucous fibrosis reported to the Department of

Prosthodontics with a chief complaint of difficulty in

chewing due to loss of teeth. Intraoral examination

revealed the presence of palpable fibrotic muscle

bands on right and left buccal mucosa and

restricted mouth opening. The diameter and

circumference of her mouth were measured, and

found to be 30mm (fig: 1c).

Prognosis and probable prosthetic treatment

options were explained to the patient and informed

consents were obtained.

Maxillary primary impression using custom

fabricated sectional trays.

Difficulties faced in Prosthetic rehabilitation of

microstomia patients begin from the preliminary impression due to minimal mouth opening and

tongue rigidity. Hence the maximum mouth

opening does not accommodate even the smallest

of the impression trays2. Insertion and removal

of impression trays are often very difficult. To

overcome this problem, various modification in

tray fabrication have evolved which includes the

use of sectional trays2 and flexible trays3 that could

be assembled extraorally.

Impression Making

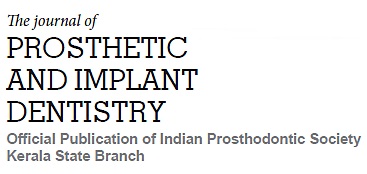

For making maxillary primary impression modified

stock metal tray was fabricated according to the

technique illustrated by K. Ashwini Kumar et al4

In this method, a stock metal tray was selected

by measuring the width of residual ridge using

caliper. The area to be sectioned was marked

on the tissue side of the tray. Later,Dental stone

was poured into the impression tray and cast was

made. This cast acted as a guide for the sectioned

stock tray. The tray was sectioned into two along

the line previously marked using a diamond disk

and the magnets were attached to the sectioned

handles with a designed reorientation mechanism.

Impression was made in two steps. The impression

of one half of the arch was made first followed by

impression of the other half. Monophase medium

viscosity impression material (Elite impression

material, Zhermack Italy) was used.

At first, the tray adhesive was applied on the both

sections of the tray and allowed to dry for 5 min.

Then the first segment of the modified impression

tray was loaded with elastomeric impression

material (Elite impression material, Zhermack,

Italy) and the impression of the corresponding

side of the arch was made. The excess material

extending medially beyond the tray was cut off,

followed which petroleum jelly was applied onto the

cut surface. Next, the second segment of the tray

was verified for proper orientation and impression

of the second half was made without disturbing

the first half. At this point, magnet incorporated, helped in holding the two segments of the tray.

The impression was taken out in segments and

was reoriented outside the mouth (fig: 2).

The impression was poured in dental plaster and

a preliminary cast was obtained.

For mandibular impression, a stock metal tray was

used according to the width of ridge.

Choosing an appropriate tray which was inserted

without any difficulty, allowed us to use a single

stock tray without sectioning and impression

was made using impression compound in a

conventional manner.

Maxillary Final impression using custom fabricated sectional trays using press

buttons:

A 2mm thick wax spacer (Maarc Modelling wax, New

Delhi) was adapted onto the maxillary primary

cast and sectioned vertically along the midline into

two halves. Maxillary custom impression tray was

fabricated using autopolymerising acrylic resin

(DPI-RR Cold cure clear) in two steps.

For the first segment,wax spacer was placed on

the cast and autopolymerizing acrylic resin was

adapted over it. A tapered brass die pin of 8mm

long was placed at an angle of 45º anteriorly in

the region of incisive papilla. This die pin served

as tray handle for this half of tray and also as a

component of anterior locking. Posteriorly, female part of press buttons were placed over the palatal

shelf 1cm away from midline that served as a

component of posterior lock.

After complete polymerization of first segment,

petroleum jelly was applied over the die pins and

also into the set acrylic to prevent fusion of two

segments. The second half of wax spacer was

adapted and acrylic resin was adapted over it to

form the second segment.

Anteriorly, acrylic resin was directly adapted

around the die pin forming a tray handle in the

second segment. Posteriorly, the acrylic plate

was extended medially over the first segment,

consisting of male part of press button forming

the posterior lock (fig: 3a & 3b).

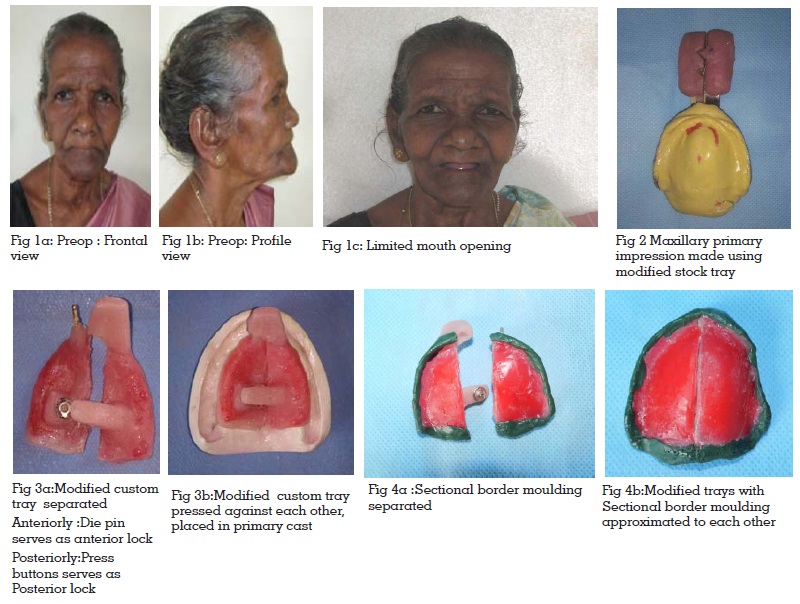

The tray was checked intraorally, extensions were evaluated. Sectional border moulding was

completed using low fusing green stick compound

(DPI)(fig: 4a & 4b). Impression of first half of tray

was made and the excess material was cut off to

flush with second half tray. The cut surface was

lubricated using petroleum jelly and impression

of second half tray was made. At this point the

tray should be squeezed at the handle and

once precise fit was ensured, snap fit buttons

were pressed firmly and allowed the material to

set. Later, snap fit buttons were unpressed and

removed separately (fig: 5a). Outside the mouth,

trays were reassembled (Fig :5b) following which

conventional prosthodontic protocol of boxing

and pouring with type III gypsum material was

followed to create a definitive cast.

A Light body polyvinylsiloxane (Elite, Zhermack,

Italy) impression material was used. A step by step procedure for making definitive impression was

carried out based on novel technique suggested

by Suryakant.C.Deogade3.

For Mandibular final impression, sectioning of

tray was not required as the whole of custom

tray was inserted without difficulty. Hence, the

conventional procedure for final impression

making was followed(fig: 6) and definitive cast

was obtained

The handle of the tray was fabricated using acrylic

resin blocks and commercially available press

buttons were used as locks which have a male

and female part. The handle with the press buttons

function as anterior and posterior locks.

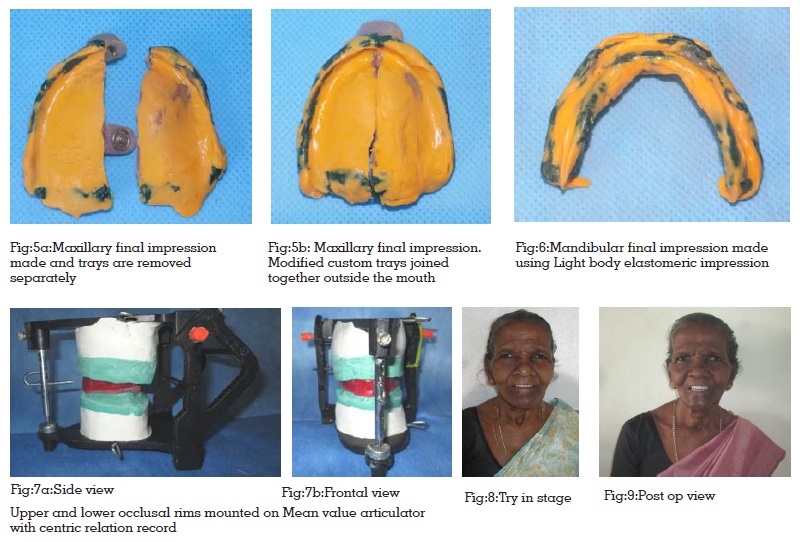

Jaw relation, Try in & Prosthesis delivery

With the obtained master cast, a permanent base

was fabricated. At this point, it was possible to place

the denture as a single piece,which eliminated the

need for construction of a sectional denture which

though would be convenient for placement would

be difficult in hygiene maintenance.

Maxillomandibular relationship was recorded

and mounted on an articulator (fig:7a & 7b).

Teeth arrangement was done;and the setup was

tried in patient’s mouth (fig: 8). The maxillary

and mandibular complete dentures were then

acrylized conventionally in heat polymerizing

acrylic resin (DPI)(fig:9).

Rehabilitation with conventional complete denture

for microstomia patients is a challenging task due

to decreased perimeter of the oral cavity. Presence

of fibrotic buccal mucosa makes manipulation of

muscles for border moulding extremely difficult. To

overcome these problems, several modifications

in tray fabrication have been illustrated in the

literature. Use of flexible trays and sectional trays

provide a helping hand in impression procedures.

Whitsitt and Battle5 described a technique for

making flexible impression trays for a microstomia patient. He had utilized silicone putty material

(Optosil, Unitek Corp., Monrovia, Calif.) that can

be inserted and molded in the mouth before it

sets. Due to its flexible nature, the silicone tray

can be easily inserted and removed. Various

authors have suggested different techniques for

fabrication of sectional trays. A variety of pins,

bolts and Lego pieces have been used for the

locking mechanism of sectional impression trays

fabricated for patients with limited oral openings6,7

Sectional impression trays have been fabricated

using recesses, orthodontic screws, Lego blocks

(Lego Systems Inc., Enfield, CT), dowel plug holes

with a screw joint for rigid connection, locking

levers, interlocking tray segments and flexible

impression trays with silicone putty.

K. Ashwini Kumar et al4 described a technique of

making sectional trays for maxillary impressions

in which magnets were attached to the sectioned

handles with a designed reorientation mechanism.

Vamsi Krishna CH et al8 described simple and

economic methods of fabrication of two-piece

custom sectional trays for patients with oral sub

mucous fibrosis.

A sectional stock tray system for making preliminary

impression was described by Luebke9. Impressions

using sectional trays may be easier for patients

with restricted oral openings because the two

halves can be inserted independently, removed

separately and reassembled extra-orally. Improved

fit of the tray was possible because the two halves

were separately fitted to each side of the arch

to achieve better anatomical adaptation to the

soft-tissues. The important requirement while

fabricating a sectional tray is the mechanism

employed to accurately adapt and stabilize the two

segments of the tray to each other both intra-orally

and extra-orally. The technique should allow easier

manipulation to decrease patient trauma. Use of

both anterior and posterior locks is important for

better stability. The technique for sectional tray

described in this report employs the use of lock

pins and press button which fulfills all the criteria.

A maximal opening smaller than the size of a

complete denture can make prosthetic treatment

challenging.

Modifications in procedural techniques help to

overcome the technical difficulties faced during

prosthetic management of patients with oral

submucous fibrosis. The technique employed for

tray fabrication is a combination of two different

lock mechanisms, which facilitated the operator

to obtain accurate impressions for patients

with restricted mouth opening. These sectional

tray designs are easier to fabricate, less time

consuming and requires relatively inexpensive

locking mechanisms.