Abstract: Complete maxillary or mandibular edentulism is considered to be the most challenging clinical condition to rehabilitate. A possible solution to provide stability and retention of the prosthesis in this condition,in a short time i.e on the day of implant surgery,is intraoral welding technique. This goal can be achieved by welding titanium bars on implant abutments directly inside the oral cavity, which decreases the risk of micromovements of implants with regard to surrounding bone and possibility of error or distortion due to prosthetic procedures.

The increase in life expectancy continuously

has brought new challenges to the dentistry, as

number of edentulous patients are increasing

in one or both arches.1 These patients often do

not accept a rehabilitation with a removable

prosthesis, for either functional or psychologic

reasons. The evolution of implant dentistry brought

an increasing interest in immediate esthetic

replacement of missing teeth. Placement of dental

implants followed by immediate loading with a

fixed, implant-supported prosthesis mimics the

biomechanics of teeth within the alveolar bone.

Biologic benefits for these patients are internal

loading on the alveolus and preventing continued resorption of the jaw bone.2

More advanced protocols decrease the healing

period, and in the case of immediate loading for

a full-arch replacement, implants are exposed

immediately to occlusal and muscular forces.

The resultant changes in both the surgical and

prosthetic protocols are remarkable and are a

significant departure from the original two-stage

protocol.2 A time saving and successful decorum

to rigidly splint multiple implants in a precise

manner is the Intraoral Welding Technique.3

Welding involves a metallurgical union process

that relies on base metal fusion, i.e. the constituent

metal of the structure, with or without the addition of

filler metal, to form the soldered joint.3 In intraoral

welding, a titanium bar is welded to the implant

abutments directly inside the oral cavity. It was

introduced by Hruska and Mondani3 in 1976.

Further it has been widely documented by Degidi

et al in 2006, who mentioned the creation of precise

and passive prosthetic structure by assembling the

framework directly inside the oral cavity.

Intraoral welding can join and support the

implants by the use of a titanium wire or bar that

is permanently connected to the implants. An

electric current for milliseconds is used to fuse the

titanium to the abutments. The welding procedure

is performed intraorally before the immediate

loading. Stabilization and fixation of the implants

allows immediate loading and prosthesis insertion (provisional or definitive) to occur on the same

day of the surgery. By inserting a prosthesis with

adequate retention and stability the same day as

the surgery, patient complaints and discomfort

can be avoided or minimized. The immediate

stability, which is a result of implant splinting can

also reduce the risk of failure during the healing

period. It can also eradicate the faults caused by

inappropriate making of impressions.4

Intraoral welding can be performed either with

a laser device - intraoral laser welding (ILW) or

by electric resistance welding – intraoral welding

(IOW). Electric resistance welding was introduced

by Pier Luigi Mondani5 in 1976 and then developed and perfected, and is based on the creation of

an electric arc between two electrodes under an

argon gas flux and it is called “syncrystallisation.’’6

Syncrystallization is the term used to describe the

union of two metallic surfaces through the sharing

of atoms constituting the crystal lattice in the joint

zone. Gordon7 discussed the probability of welding

metallic portions of dental prosthesis using laser

technology in 1967. According to many authors,8

laser technology is one of the best among all of

three welding techniques, which can be used

for different metals and it is the most effective

method for delivering thermal energy to small

areas as it permits the generation of a keyhole

that effectively concentrates the energy input

into one small area. Resistance to corrosion and

mechanical strength of the welded joint can also be improved with laser welding.7 Shielding gases

used in laser welding units shield the molten metal

from oxidation but there are some limitations to

welding such as porosity and cracks, which can

be reduced by vaccum welding. Carlo Farnaini

et al.(2014)9 reported that peak power is the

most significant parameter while determining the

penetration depth which is equal to pulse energy

per pulse duration. If the peak power is increased

too much, the temperature of the alloy exceeds to

the evaporation point, it will cause crater formation

on surface of the materials.

Historically, the welding machine was officially

introduced in the early 1970s, while the technical

description of this invention was only published

later in 1982.10 In the seventies COMEPRE Company

collaborated with Dr. Pier Luigi Mondani10 to

develop ‘’Syncrial’’ the first intraoral welding

machine allowing the welding by syncrystallization

of scialom needles by spot welding points, of

parts or of metallic implants also already firmly

implanted in the bone tissue.11 Initially, however, no

one except the inventor dared to use an electrical

device (Endoral welder) that had to reach a melting

point of 1678° C in order to solder –inside the oral

cavity - the ends of metallic artifacts placed in the

bone. Later Mondani’s technique was employed

at the Specialization School of Dentistry of the

University of Modena, where it was tested and

certified as safe, and reported that it does not

harm the tissues with which it comes into contact.

The “biocompatibility” of the soldering, which

occurs at 1678°C on the protruding and closely

set portion of the needles placed in living tissue,

is due to the fact that the electric current needs a

working time of just 2–3 milliseconds. This microtime,

combined with the calculated pressure of

the electrodes on the structures to be soldered,

prevents the diffusion of the tremendous heat

gradient beyond the welding point. Apart from

being a bad conductor, titanium also has low

thermal conductivity which is very similar to that of enamel.12

Nowadays Intraoral Welding devices are available

in various companies such as Dentsply, ITS Italy,

Swiss & Wegman etc. Recent Intraoral Welding

devices are based on the resistance spot welding

principle. They provide a stable and passively

fitting framework for temporary or durable

prostheses for immediate restorations – suitable

for immediate or late loading on the same day

of surgery.

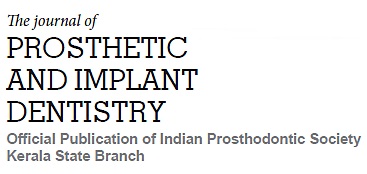

After the implant site selection, implant are placed

with widely possible antero posterior distribution

using surgical template. Angulated abutments

are connected to the implants immediately after

the implant placement. First, a so-called welding

abutment, a titanium cylinder, is connected to each

abutment with a long pin screw. A 2.0-mm-diameter

bar made of grade 2 commercially pure titanium

is welded to the most distal abutment on the left

using an intraoral welding unit. The bar is then

adjusted with orthodontic utility pliers to passively

contact all the abutments. The whole welding

process is divided into three parts: Preparation,

Welding, and Cooling stage.13 In the Preparation

stage, two electrodes of the welding pincers are

placed on either side of the bar and the abutment,

both of which must be clean and free of surface

oxidation. The copper electrodes at the extremities

of the pincers are gently put into contact with

the parts to be welded and firm pressure is then

applied (Fig1). It is important to maintain complete

contact between the curved bar and the welding

abutment during the entire process. Firm and

constant pressure must be constantly applied

to ensure a perfect joint between the parts to be

welded. The presence of water or saliva does not

compromise the quality of the welded joint. The

surgical team and the patient must wear protective

goggles during the entire process.”

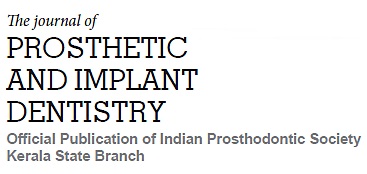

In the Welding stage, An electrical charge from a previously unloaded capacitor is transferred

to the copper electrodes of the welding pincers.

Electrical current which is supplied to the

electrodes instantly raises the temperature of

the two titanium components to fusion point (Fig

2). The process takes only 2 to 5 ms to carry out

and brings the core of the titanium parts to a

temperature of nearly 1,660°C. A barely perceptible

clicking sound can be heard during this phase.

This procedure is performed without the use of

any additional filler metal.

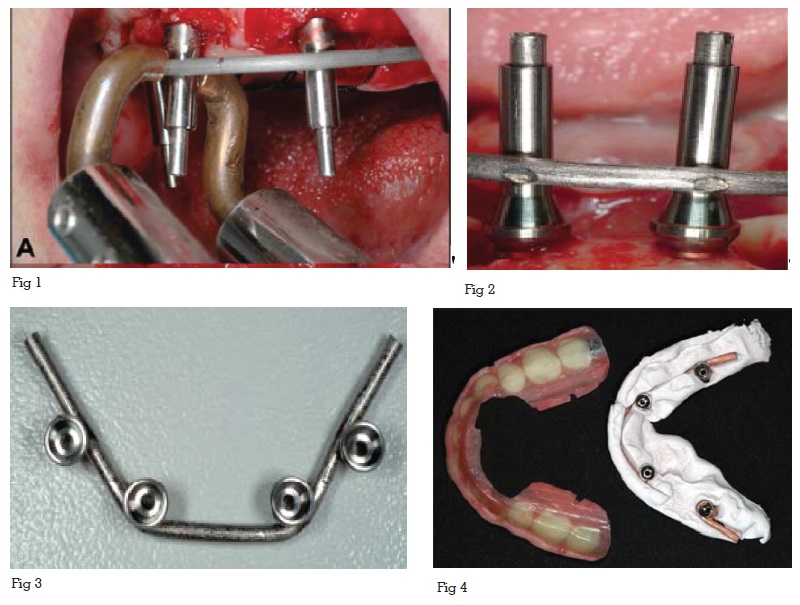

In the cooling stage, the titanium crystallizes. To

avoid crystallization of titanium, the bar and the

abutment must be kept under firm pressure and if

all of the instructions are followed properly, a solid

joint is formed. The only way the process can fail

is if there is inaccurate positioning of the titanium

components or if insufficient pressure is applied

during the welding and cooling stages. If either of

these occur, the joint obtained is very unstable and

fragile. After the welding, the prosthetic framework

is removed (fig 3) and its passivity is checked with

the Sheffield 1-screw test. The welding abutments

of the framework are screwed to analogs of the

angulated definitive abutments and are inserted

in cast model. Framework is finally refined to fit

the prosthesis (fig 4).

If more rigid structure is required or if titanium bars

are used with thin diameters, an additional bar

can be welded onto welded abutments, following

the exactly same procedure as for the first bar

removing the structure after each welding to check

for passive fit of the prosthesis.14

Bars can be welded in various ways

Advantage of intraoral welding procedure is to

create a very precise rigid framework quickly and

directly inside the oral cavity, when immediate

functional loading is planned.15 Rigid framework

splinting obtained by this technique, can limit

the micromovements in immediate loading

protocols and is indicated in partial and fullarch

prosthesis, which reduces the mechanical

stresses exerted on each single implant and

assure an optimal distribution of occlusal load

and decreasing the lateral forces on healing

implant. With this technique, time-costly laboratory

steps can be avoided, such as the creation of

a customized impression tray, while a passive

fit of the framework is easily obtained.16 When

implants are splinted together, partial and full

arch immediate restorations can be performed

under low insertion torque. This reduces the

micromovements of weaker implants and hence

in turn increases the osseointegration.17 No major

limitations have been reported to this technique.

“Unfortunately, there are more limits to

syncrystallisation and electric resistance welding,

as these are not effective on every kind of metal

and alloy, and these cannot be used on patients

with pacemaker. Among the techniques, laser

technology found to be the most efficient method

for delivering thermal energy to small areas. It

is one of the best fusion welding techniques for

different metals.18 This depends on the ability to

focus the light beam in a focal point. The best

advantage is that the weld process can usually be

performed exactly where it is required, that is, at

the level of an implant abutment.19 Moreover, the

procedure can be carried out directly on the master

cast, thereby eliminating the risk of inaccuracies

and distortions due to the duplication of the model

and the heat source, being a concentrated highpower

light beam, and minimizing the distortion

problems in the prosthetic pieces.20

The clinical use of the intraoral welding technique

to immediate load the implants surgically inserted with computer assisted surgery reported to be

a good treatment approach nowadays, which

allows the creation of an immediate and

passive provisional restoration that could limit

complications reported in the past and reduce the

intraoperative time with respect to the traditional

technique of intraoral welding.21

Titanium bars welded intraorally on prostheses is

now a widely proven technology and allows the

stabilization of fixed prostheses in edentulous

ridges that otherwise could not be rehabilitated.

The welded joint structure reported excellent

microstructural quality, with only minor porosity

detected at 50,000× magnification. Welded joint

between abutment and titanium bar after subjected

to functional loading showed no fracture or

radiographically detectable alteration, improving

the quality of the results,reducing the operative

time, and giving greater comfort to the patient.22