Cranioplasty is a surgical intervention utilizing

an implant material to repair cranial defects

both functionally and aesthetically. The cranial

implant not only protects the brain but also provide

cosmetic results. The most important advantage

of cranioplasty is it improves the neurological

deficit by decreasing local intracranial pressure

besides improving the dynamics of CSF changes1.

Cranioplasty can also aid in postural blood

regulation, cerebrovascular reserve capacity

and glucose metabolism within the brain. This

article presents the rehabilitation of a patient with

acquired skull defect using custom made titanium

implant prosthesis.

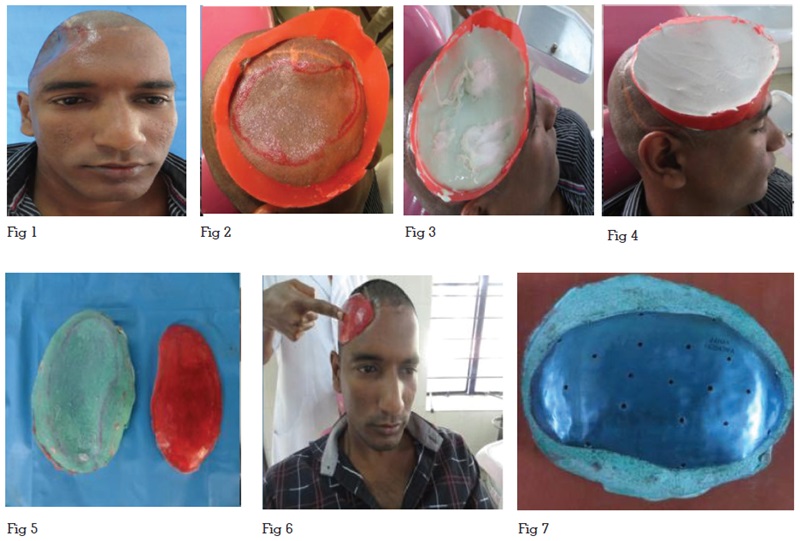

A 32 year old male patient reported to the

Department of Prosthodontics, Government Dental

College, Kottayam referred from the Department

of Neurosurgery Government Medical College,

Kottayam for the management of an acquired

cranial defect. The patient had a previous history

of road traffic accident (RTA), resulting in an open

head injury with right temporo-parietal contusion

and fracture of the squamous part of temporal

bone. The patient was treated immediately with

a right fronto-temporo parietal craniotomy by the

neurosurgeons. Post operatively it was found that

the patient had lateral hemiplegia on the left side and a large bony defect of 15cm × 12 cm size on

the right side of the skull [Fig-1]. It was planned

to close the defect using custom made titanium

cranial prosthesis.

The construction of any maxillofacial prosthesis

with an alloplastic material consists of several

stages, each of which is equally important to the

success of rehabilitation. These stages include

moulage impression, working cast fabrication,

sculpturing the pattern, mould fabrication and

processing of the final prosthesis2. Impression

procedure was planned at the first scheduled

appointment. Patient was instructed to report

after shaving off hair from the face and head

to facilitate impression procedure. Accuracy of

delineating margins of the cranial defect is an

important step in impression procedure. This was

achieved by palpating the margins of the defect

and marking 2-3 mm beyond the outermost borders

of the cranial defect using an indelible pencil.

Once the margin of the defect was established,

modeling wax (MAARC-MODELLING WAX) was

adapted along the periphery to limit the flow of

irreversible hydrocolloid impression material.

(DPI- NEW ALGITEX) [Fig-2]. Petrolatum jelly was

painted on the tissue further for ease of removal

of impression material. A thin mix of (DPI- NEW ALGITEX) impression material was then carefully

poured onto the defect area taking care to avoid

air trap [Fig. 3]. After placing cotton tufts onto

the setting impression material, a second pour of

lightly mixed plaster of Paris was placed over it to

provide support to the impression material [Fig. 4].

Once the impression material was set, it was

removed carefully, evaluated and poured with

type 3 dental stone (GOLD STONE-GREEN STONE

PLASTER) to obtain the master cast. Outline of the

defect marked on the tissue which was transferred

on the impression was highlighted with indelible

pencil, so that this marking could be transferred

to master cast, for fabrication of wax pattern [Fig. 5]. The master cast was painted with separating

medium for ease of removal of wax pattern.

The design of the final cranial prosthesis was

discussed with the neurosurgeons, and the wax

pattern was fabricated following the contours of the

skull on the master cast. On the second scheduled

appointment wax pattern was tried on to evaluate

the fit along the margins of the defect. The contour

of the wax pattern was corrected from all the three

sides(frontal, sagittal and occipital) to restore

the normal contour and appearance [Fig. 6]. A

titanium cranial prosthesis was fabricated from

the wax pattern [Fig. 7]. The patient was again

recalled for trial of the custom made titanium cranial prosthesis to check for shape and fit of the

prosthesis from all the anatomical aspects [Figs.

8, 9].

The surgical procedure involved the preparation

of scalp with an antiseptic solution and the

reflection of the scalp with a U shaped incision

to completely expose the bony margins of the

defect, titanium screws were used to secure the

titanium prosthesis into the exact position and

the defect was closed [Figs. 10, 11, 12]. A closed

system suction drain was placed immediately after

surgery to reduce the postoperative hematoma.

The drain was removed after 48 hours following

which the patient had a good recovery. The patient and his parents were instructed for the care of the

reconstructed area. Post surgically the contour of

the defect was satisfactorily reconstructed from

all the anatomical aspects.

Besides protection of the underlying brain, the

prosthesis helped to repair the contour of the

vaults providing satisfactory esthetics [Figs. 13].

Cranioplasties have been performed since the

early 1950s1. Many different types of materials

were used throughout the history of cranioplasty.

The advancement in biomedical technology, have provided new materials for prosthetic rehabilitation

An ideal cranioplasty material must have the

following features5.

More importantly, a cranioplasty material that

fulfills all these characteristics is yet to arrive.

Common materials used in the field of cranioplasty

are4, autografts (cranium, tibia, rib, scapula, fascia,

sternum, ilium), allograft, xenograft, nonmetal

allograft (celluloids, methyl-methacrylate, hydroxyl

apatite, polyethelene,silicon, choral, cortoss,

ceramic), metal allograft (aluminium, gold, silver,

tantalum, stainless steel, titanium, lead, platinum,

vitallium, ticonium) and polyether ether ketone

(PEEK) etc.

Developments in endoscopic equipment have

given the surgeons the opportunity of minimally

invasive cranioplasty technique called endoscopic

cranioplasty. With endoscopic tools materials

such as acrylic and hydroxyapatite can be

administered through small incisions. Although

minimal invasiveness is an advantage, there is

still lack of evidence from large patient group to

support this method.

Interests in acrylic resins among neurosurgeons

increased considerably following Spence’s 1954 report of a simple method for fabricating implants at

the time of surgery, using auto polymerizing methyl

methacrylate3. Advantages of acrylic implants are

dimensional stability, non-conductivity, lower cost

and ease of modification and placement4. However

methyl methacrylate can cause exothermic

reactions, which may damage the surrounding

tissue and lead to subgaleal exudative fluid and

infection6,7. The major advantages of titanium over

methyl methacrylate are low modulus of elasticity,

low density and very low rate of corrosion. Besides

this it is nontoxic, elicits no inflammatory reactions

and has an infection rate under 2%7,8,9. Moreover, it

is robust enough to resist secondary trauma while

providing maximal stability of the cranial vault5.

Holes of 2mm dimensions were drilled onto the

surface of the titanium prosthesis to prevent the

development of epidural hematoma and allow for

ingrowth of fibrous connective tissue to assist in

stabilization. Furthermore, the holes help to secure

the prosthesis to the bony defect10.

Although computer aided design and

manufacturing (CAD-CAM) generated titanium

cranial prosthesis have been introduced, the cost

of this prosthesis is a major concern.

Researches on both biologic and non-biologic

substitutes for cranioplasty are going on worldwide.

Stem cell experiments and development of

morphogenic proteins are expected to take place

in the short-term future4.

Cranioplasty is one of the most common surgeries

performed in trauma settings. Rehabilitation of

cranial defects using custom made titanium cranial

prosthesis will reduce adjustment of prosthesis

during the surgery. This case report describes an

effective, economical and simple technique for

rehabilitation of a person with acquired skull defect

using a custom made titanium cranial prosthesis.