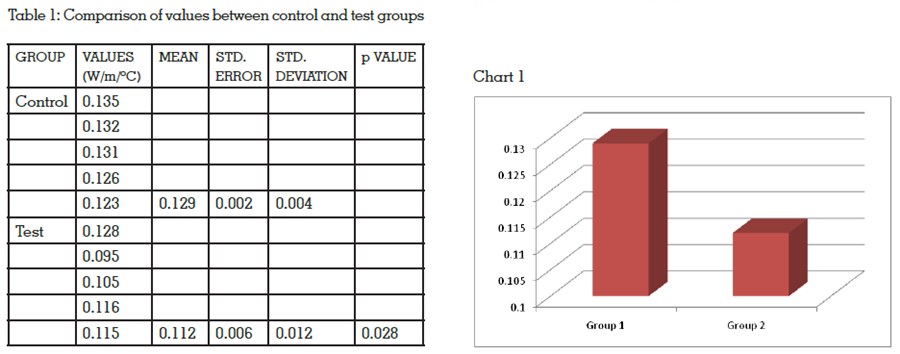

Purpose: To evaluate whether the incorporation of graphene nanoparticles to PMMA improves its thermal conductivity properties. Materials and Methods: In this in vitro experiment, samples of 10 PMMA acrylic disks, 5 disks with graphene nanoparticles (test group) and 5 disks without graphene nanoparticles (control group) were fabricated and subjected to thermal conductivity testing. The sample disks were placed between the two plates of the instrument. The results were analyzed using the Mann Whitney U- test (p<0.05). Results: PMMA disks without graphene additives showed superior thermal conductivity than the test group (p= 0.028). Conclusion: Under the given conditions, acrylic disks with graphene additives did not conduct heat more than the disks without graphene additives. Sographene did not significantly improve the thermal properties of PMMA.

Key words: graphene in dentistry, thermal conductivity, polymethyl methacrylate

Various biomaterials are used in Prosthodontics

to fabricate removable prostheses for completely

and partially edentulous patients. One of the

most commonly used materials with decades of

evidence is polymethyl methacrylate (PMMA).

Polymethyl methacrylate has stood the test of time

as a denture base material and holds its efficacy

as a satisfactory denture base material till date.

It was introduced in the year 1937 by Dr. Walter

Wright and has its pros and cons1.

PMMA has been employed successfully as a

denture base material owing to its light weight,

ease of fabrication, low cost, acceptable aesthetics,

biocompatibility, low water sorption, and

adequate strength; at the same time, it has certain

disadvantages such as low fatigue resistance,

low coefficient of elasticity and low thermal

conductivity. Among these, of prime concern is the

low thermal conductivity of PMMA which reduces

the gustatory response and palatability of food

for the patient2. Improved thermal conductivity

of polymethyl methacrylates would be a boon to

removable denture wearers thereby resulting in

enhanced the acceptance of these dentures.

“Thermal conductivity, of a substance, is defined as the quantity of heat in calories, or Joules, per

second, passing through a body 1 cm thick with a

cross section of 1 cm square when the temperature

difference is 1-degree Celsius”. The value of

thermal conductivity for PMMA is 0.2 W/m/degree

Celsius3.

To overcome this shortcoming, various materials

have been used to improve the thermal conductivity

of PMMA. Metal oxides like aluminium oxide,

titanium oxide, zirconium oxide, silicon carbide

filler powders, hydroxyapatite ceramic powders,

silver nanoparticles, and carbon particles have

been incorporated and have improved the thermal

conductivity without affecting the strength of the

acrylic denture base. Also, metal denture bases

have been used by many clinicians to overcome

this disadvantage1,4,5.

The present study was conducted to test if the

addition of a material, named Graphene, improved

the thermal properties of dental polymers or not.

Graphene which is a basic construction of graphite

consists of carbon atoms arranged in a honey-comb

structure in the form of flat thick sheets. It has broad

potential applications in biomedical engineering

and biotechnology, such as in DNA detection, drug delivery, cancer therapy, etc. Owing to its various

excellent mechanical, thermal, electrical and antimicrobial

properties6,7,8 graphene is now being used

in dentistry for detection of bacteria in dental caries

and periodontal disease, in restorative dentistry

for strong dental fillings that do not corrode in the

oral cavity, as fillers in dental adhesives to prevent

secondary caries, in bone tissue engineering, in

periodontal tissue regeneration, in cancer therapy,

as coating on implants to improve osseointegration

and lastly its antibacterial properties which kills

bacterial cells through cell- wrapping and celltrapping

mechanism. Due to these enhanced

capabilities, graphene is being incorporated in

dental biomaterials such as metals, ceramics,

and polymers. Different graphene derivatives can

achieve good dispersion within different polymers

and can be easily processed8.

Previous studies have proved that the addition of

graphene to PMMA does not affect the impact and

flexural strength. They are also biocompatible and

nontoxic in the oral cavity. Graphene has been

proved to be a superior thermal conductor in other

biomedical applications. But this valuable property

has not been investigated in dentistry so far6.

Swami P, Sanyal P, Guru R, Kore A9 evaluated and compared the addition of graphene and carbon

fillers on the flexural and impact strength of PMMA.

They concluded that 0.5% by weight of carbon

fillers increased the flexural and impact strength

of PMMA followed by graphene combined with

0.25% carbon and 0.25% graphene nanofillers.

Guazzo R10 reviewed the uses of graphene

nanomaterials in dentistry. They discussed the

interaction between graphene nanomaterials with

immune system cells and antibacterial activity of

graphene nanomaterials. They concluded that

further studies are required to evaluate the possible

long term toxicity and their derivatives in the oral

cavity. Malik S11 described a new,easy and low-cost

method to make large amount of FLG few layered

graphene with multi-layered graphene and its

inclusion into dental polymers. It was concluded

that the new few layered graphene material

incorporated in the dental polymer enhanced

the physicomechanical properties as there was

27% increase in mean compressive strength and

mean compressive modulus increased by 22%.

Shradhanjali A, Bouzid T, Sinitskii A, Lim J12

and Kulshrestha S et al7 reviewed the use of

graphene for dental implant applications.

Osseointegration of dental implants has been proven to improve after coating the implant surface

with graphene oxide and reduced graphene oxide.

The osteogenic differentiation of mesenchymal

stem cells significantly improved on the implant

surface and also increased the antibacterial

properties. But further studies have to be done

to reveal how graphene-based implant coatings

would produce better implant actions. Lakshmi

K, Rao GU, Arthiseethalakshmi S, Mohamed

MSK13 reviewed the properties, manufacturing

methods, applications of graphene in general

and biomedical fields and also in dentistry.

In dentistry graphene is used for detection of

bacteria in dental caries and periodontal disease,

in restorative dentistry for strong dental fillings

that do not corrode in the oral cavity, as fillers in

dental adhesives to prevent secondary caries,

in bone tissue engineering, in periodontal tissue

regeneration, in cancer therapy, as coating

on implants to improve osseointegration and

antibacterial properties. Thus, they concluded that

further research is needed for its use in dentistry.

The aim of this study is to investigate whether

the addition of graphene nanoparticles in PMMA

improves the thermal conductivity. Null hypothesis

of this study is that the addition of graphene nanoparticles in PMMA does not affect the thermal

conductivity.

Two stainless steel disks were constructed by

cutting solid stainless steel plates into the desired

shape and dimension of 50 x 2±0.5mm (Fig.2)14.

Ten putty molds, (Virtual, Putty Base Regular Set,

Ivoclar Vivadent, Italy) five from each disk were

fabricated. From these molds, ten acrylic (DPI-RR

Cold Cure, Dental products of India, Mumbai)

specimens were made, five without graphene

additives to serve as a control group and five with

graphene additives (UGRAY, United Graphene,

United Nanotech Innovations Pvt. Ltd, Bangalore)

to serve as a test group (Fig.3).

An electronic balance (Shimadzu, India) was used

to measure the graphene and polymer powders.

2% by weight of graphene (particle size of 25μm)

was added in 100g of polymer: 33ml of monomer

for the five test samples9. Similarly, the control

samples were prepared using the same polymer:

monomer ratio without the addition of graphene.

The acrylic mixture was then poured into the putty

molds and polymerized in a pressure pot (Vertex,

curing pressure pot, Multicure) at 10MPa for 30

minutes. The polymerized disks were then finished and polished using tungsten carbide trimmers

and silicone burs.

The samples thus obtained were tested using a

thermal conductivity instrument (Unitherm Model

2022, Pittsburgh, USA)(Fig.4). This instrument uses

the guarded hot plate principle to conduct heat15.

Two plates, namely a hot plate and a cooling

plate are in built in this instrument. The sample

material was set between the two plates. One

plate was heated and the other plate was cooled.

The temperature of the plates were observed until

they were constant (mean temperature of 55℃

was maintained). The steady-state temperatures,

the thickness of the sample and the heat input

to the hot plate were used to calculate thermal

conductivity of the samples.

The results thus obtained were subjected to

statistical analysis using the Mann Whitney Utest,

a non-parametric test which considers the

magnitude of the differences via ranks to test if

two samples come from identical populations.

The values obtained for the control group without

the addition of graphene ranges from 0.123 W/m/

ºC to 0.135 W/m/ºC with a mean of 0.129 and a

standard deviation of 0.004(Table 1). The values

for the test group ranges from 0.115 W/m/ºC to 0.128 W/m/ºC with a mean of 0.112 and standard

deviation of 0.012 (Table 1). The p-value was

found to be 0.028. This shows that the values

have decreased consistently for the test group

when compared to control group. The p-value is

less than 0.05 which proves that the results are

statistically significant.

Polymethyl methacrylate has been dominating

the dental industry for many years due to its near

ideal mechanical and physical qualities. Numerous

studies have been conducted in the past to enhance

these properties by incorporating various fillers

and fibers16,18. The enhancement of the thermal

conductivity of PMMA has been experimented

using materials like aluminium oxide, titanium

oxide, zirconium oxide, silicon carbide filler

powders, hydroxyapatite ceramic powders, silver

nanoparticles and carbon particles17,19.

In the present study, ten acrylic disks measuring 50

x 2±0.5mm were fabricated for thermal conductivity

testing, five with graphene additives and five

without graphene additives. These disks were

polymerized and subjected to thermal conductivity

testing. The values thus obtained were subjected

to statistical investigation using Mann Whitney

U non-parametric test. The p-value was found to

be 0.028 (p<0.05). This shows that the study is

statistically significant and the null hypothesis

is rejected.

Results prove that thermal conductivity had

reduced for the test group when compared to the

control group. Thus, the addition of graphene

additives has reduced the thermal conductivity

of PMMA. The possible reasons for this finding

could be the proportion of graphene in polymer/

monomer was inadequate. The quantity of

graphene incorporated in the test samples lead

to an acceptable discoloration which can be used

for characterizing dentures. But the addition of more amount of graphene led to an unaesthetic

dark discoloration of the material which would be

unsuitable for fabricating the prosthesis9. Also,

there could have been agglomeration of graphene

particles since they were not subjected to a process

called as ultra probe sonification9. The thermal

conductivity instrument (Unitherm 2022, ASTM E

1530, CIPET/PTC/027. Anter Corporation, USA) can

conduct heat equally only if the sample thickness

is constant throughout with a variation of ± 0.5mm.

There could have been possible variations in

the thickness of the sample while finishing and

polishing,this could have lead to varying values.

The study was conducted involving a small sample

size, further investigations can be done using a

larger sample size. Also, heat cure denture base

can be used.

Within the limitations of the present study, it can be concluded that,