Statement of problem: Screw loosening of dental implants is one of the most common problems in prosthodontic practice. Despite known factors for screw loosening, the possible role of torque magnitude as a function of preload on the implant surface morphology must be explored to further understand the problem of screw loosening. Purpose: To evaluate the surface morphology of implant abutment screws under different torque magnitudes. Materials and methodology: Dental implant abutment screws of CMI, Neobiotech, South Korea were torqued to 15, 20, 35 and 45 Ncm on its corresponding laboratory implant analogue (3.5 X 11.5 mm). Using scanning electron microscopy (SEM) imaging, the torqued abutment screws were evaluated for any surface irregularities and thread wear. Results: SEM analysis of the torqued abutment screws revealed notching, stripping and wearing of the threads. The severity of altered surfaces increased with torque magnitude, compared to the absence of wear on the untorqued control abutment screws. Conclusion: Repeated tightening and loosening of titanium abutment screws can lead to thread wear and stripping. The chronic event of the above phenomenon can lead to screw loosening and further screw fracture. Studies on enhancing the abutment screw coatings with materials of reduced coefficient of friction can decrease the incidence of screw loosening and clinical adherence to replacing loosened abutment screws of implant patients with a new abutment screw is recommended to avoid screw fatigue and fracture.

Key words: Dental implants, Implant abutment screw, Screw loosening, Preload, Implant prosthetics

Though osseointegrated dental implants are the

most predictable treatment of tooth replacement,

long-term studies have shown presence of

prosthetic complications, such as screw loosening

and screw fracture. Problems associated with the

integrity of implant –abutment screw joint assembly

continue to be a perplexing clinical predicament

for prosthodontists.1,2 Abutment screw loosening

is a recognized obstacles in successful prosthetic

implant restorations and one of the common

causes of restoration failures. In particular, the

incidence of screw loosening of 33 % has been

reported in single implant supported restorations.3

Treatment of such prosthetic complications are

further expensive and time consuming for both

patient and the clinician. Concerted efforts by the

implant manufacturers and clinicians are required

to impact the above-mentioned complications.

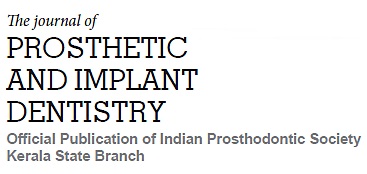

Factors such as preload, bending of screw joint,

settling effect, coefficient of friction, screw material,

connection geometry, implant number, implant

diameter, restoration design and occlusal table

influence the incidence of screw loosening. The

influence of each of these factors is schematically

illustrated in Fig. 1.

It is known that repeated tightening of the abutment

screws can lead to the loss of the preload. The

application of force while retightening could further lead to cold welding or fracture of the abutment

screw. The surface changes on the abutment screw

while torquing that occurs at a microscopic level

are usually not evident clinically. Understanding

wear of abutment screw at a microscopic level may

help decipher the mechanism of screw loosening.

Therefore, we aim to investigate the influence of

torque magnitude on the surface morphology of

abutment screw.

A CMI Neo Biotech dental implant lab analogue

(3.5X 11.5 mm, N2658-26, South Korea) was mounted

in type III dental stone (Kalabhai, Mumbai, India).

Five unused CMI Neo biotech implant abutment screws are manually torqued to the lab analogue

to the values of 0 Ncm, 15 Ncm, 20 Ncm, 35 Ncm

and 45 Ncm. With the control abutment screw,

the experimentally torqued abutment screws to

15 , 20 , 35, and 45 Ncm are labeled as screw A,

B, C, and D respectively. The torque screws were

cleaned in ethyl alcohol in an ultrasonic bath to

remove residues and impurities. The abutment

screws were further subjected to scanning electron

microscopy (COX IEM-30, South Korea) under

magnifications, 75X and 250X to evaluate surface

morphological changes of torque abutment screws

such as surface irregularities, chipping, stripping

and thread wear.

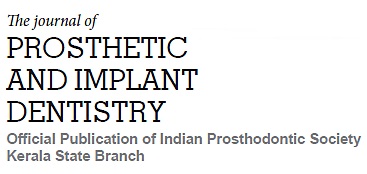

Scanning electron microscopy of the control

abutment screw, reveals smooth threads under

low magnification and minor notches under high

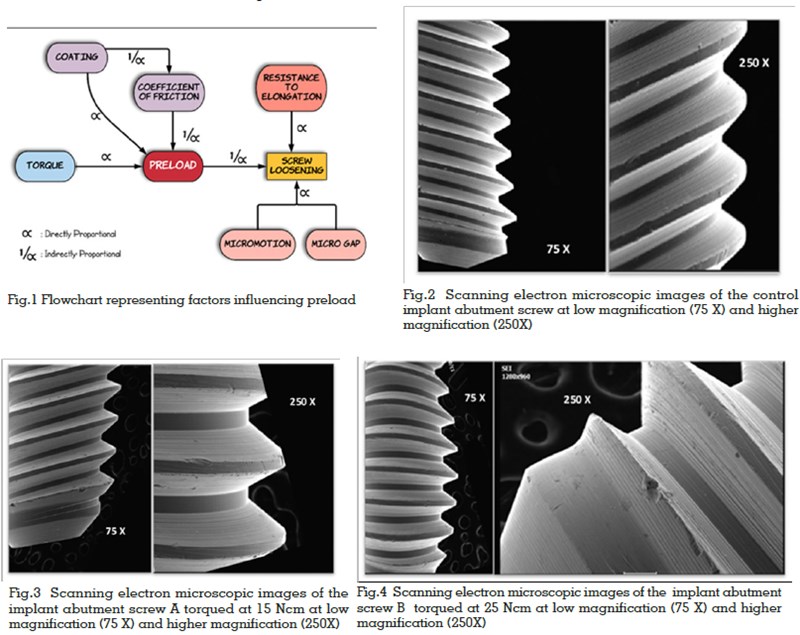

magnification as seen in Fig.2. Further, screw A

(torqued to 15Ncm) shows uniform thread surface

at low magnification with minor notching at higher

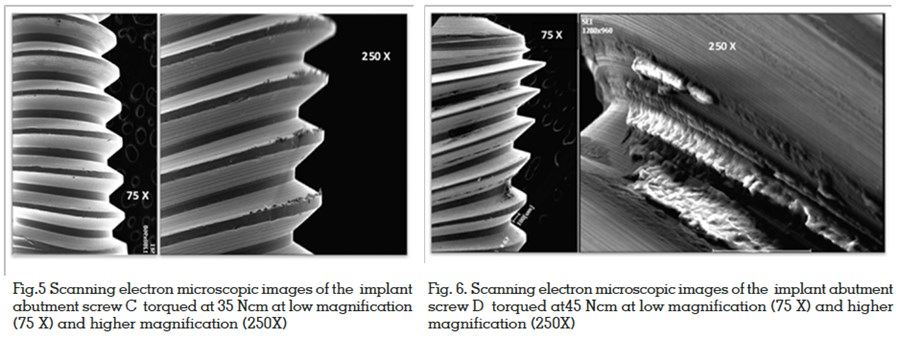

magnification as seen in Fig.3. Screw B (torqued

to 25Ncm) also shows uniform thread surface at

low magnification with marked notching at the

apical threads as shown in Fig.4. Screw C (35Ncm)

revealed surface irregularities which were more

pronounced and were present along the entire

length of the screw as can be deciphered from

Fig.5. Furthermore, with increase of torque, screw

D (torqued to 45Ncm) shows extensive stripping

at low magnification and at higher magnification

showed severe wear of threads all along the length

of the abutment screw as seen from Fig.6.

The secure connection of the implant-abutment

surfaces often depends on the preload applied

by a predetermined amount of torque during

abutment placement on the dental implant.

Clinically, decrease in the torque value has been

reported when the implant system is in function

over occlusal load.4 Preload of an abutment or prosthetic screw is the initial load created by the

application of a torque on the screw that results

further in its elongation. Preload places the screw

in tension and leads to an over-clamping force

between the parts of the implant system. The aim

of tightening a screw using preload stress is to

maximize the fatigue life of the screw yet provide

satisfactory resistance to loosening. There are

factors that influence the preload such as the

torque magnitude, screw head design, thread

design, composition of metal, component fit,

surface condition, and diameter of the screw.5

It can be deciphered from Fig.2-6, that an increase

in insertion torque results in greater wearing of the

abutment screw threads. The surface irregularities

and notching appear to start from the leading edge

of the apical section of the screw with the torques

of 15Ncm and 25Ncm and seem to progress along

the entire length of the abutment screw at 35Ncm.

The abutment screw torqued at 45Ncm showed

extensive stripping. Increased torque magnitude

can damage the abutment threads, reduce the

preload over a period of time and further lead to

screw loosening and under constant load, lead

to fatigue and fracture. The results of the study

are further confirmed by the incidence of higher

preload resulting in reduced micromotion with a

more stable joint assembly.2

To overcome the above stated problem of

preload loss and prosthetic complications of

screw loosening and fracture, abutment screws

with modified or enhanced surfaces have been

promoted to help reduce the coefficient of friction

and generate greater rotational angles and

preload values.6–8 Several implant manufacturers

attempted to lessen the incidence of screw

loosenings through coatings on the abutment

screws. Implant Innovations Inc (3i, West Palm

Beach, Fla.) tailored the palladium-gold abutment

screw surface with a solid gold lubricant with

0.76 μ thickness to decrease the coefficient of

friction and increase preload by 24%. Further,

Steri-Oss (Nobel BioCare USA, Yorba Linda, Calif.)

modified the surface of its titanium abutment screw

through a polytetra fluoroethylene polymer (Teflon)

spray coating to decrease friction by 60% and

increase fatigue strength.7–9 When titanium slides

in contact with other metals of similar hardness,

the coefficient of friction is initially low; however,

with repeated tightening and loosening, the values

of coefficient friction gradually increases to that

of titanium implant against titanium abutment

surfaces.7,9 This increase in the friction coefficient

to galling (wear caused by adhesion between

two sliding surfaces) and seizing (cold weldingactual

freezing together of the threads) tendency of

titanium alloys. Reducing the coefficient of friction

and enhancing the tightening speed, increases

the angle of turn of the coated abutment screw at

the target torque. As the angle of turn increases,

the elastic energy and preload also increases.

Additionally, an increase in the coefficient of

friction, increases the frictional dissipation energy

leading to a decrease in preload.7

Limitations of the study are that the cyclic

loading was not used as it could have simulated

the masticatory cycles, use of manual torque

wrench instead of digital torque wrench, use of

single implant manufacturer and using torque

magnitude as a function of preload. The results can further be validated through evaluation of

surface roughness parameters such as Ra, Rq with

Optical Profilometer and Atomic Force Microscopy.

Repeated tightening and loosening of titanium

abutment screws lead to thread wear, stripping

and eventually screw fracture. Understanding the

effect of the coefficient of friction and tightening

speed on preload can improve the stability of

joint surface characteristics, tightening speed and

reduce the incidence of screw loosening. Clinically

replacing the loosened abutment screw in a patient

with a new abutment screw is recommended and

a safer choice to prevent prosthetic complications.