Statement of problem: Movement of impression

copings inside the impression materials prevents

transfer of the 3-dimensional spatial orientation of

intra-oral position of implant fixtures to the working

cast. .So for the long term success of implant an

accurate and passive operation is required.

Purpose: This in vitro study evaluated the accuracy

of the master cast using different splinting and

impression materials.

Methodology: A reference mandibular model with

4 internal connection implants was fabricated.

Thirty six custom trays were fabricated using

autoplymerizing resin. Polyether and poly vinyl

siloxane impression material were used. These trays

were randomly divided between the two groups, with

eighteen trays in each group. Impression techniques

were divided into two groups namely: Group I: Direct

impression technique with open tray impression

copings splinted with autopolymerizing acrylic

resin (GC pattern resin). Group II: Direct impression

technique with open tray impression copings

splinted with Pro‑temp TM 4 (bis‑GMA) syringable

temporization material. Thus, final impressions were

made. Master casts were fabricated and evaluated

using profile projector. These measurements were

compared to the measurements calculated on the reference mandibular model which served as control.

Data were analyzed with a one way analysis of variance

at a =.00, followed by post hoc Tukey’s test test (a=.00).

Results : Statistical comparisons were made using

ANOVA test and post ‑hoc test. Same amount of

deviation values obtained with resin splinted and

bis‑GMA splinted impression copings. There was a

significant difference in-- while using Polyether and

poly vinyl siloxane as impression material.

Conclusion: The master cast obtained by both the

splinting material exhibited no difference from the

reference model. In the direct techni¬que, polyether

showed better results in terms of accuracy. Splinting

provided more accuracy of transfer in multiple abutments

using both the impression materials included in the

study .Both splinting materials showed comparable

amount of deviation from the reference model, any

one of the material based on the ease of handling, time

consumption, technique sensitivity and availability

can be chosen.

Key words: Accuracy, Open tray implant impression, Master cast, Splinting materials

Dental Implants have bought revolutionary

changes in treatment of partially and completely

edentulous patients. Implants are different from

natural teeth as osteointegrated. Implants have

no periodontal ligament to compensate for any

accuracy. As implants are functionally ankylosed

with direct contact to the bone, they lack the

inherent mobility of periodontal ligament. Hence,

they cannot accommodate distortion or misfit at

the implant abutment interface.1 Consequently

recording the intraoral three-dimensional position

of implant is more challenging in the realization

of implant-supported than in tooth-supported

prosthesis to ensure an accurate relationship

on the master cast. A successful result can be

achieved only when passively fitting prosthesis

are fabricated.2 Poor fit of framework connected

to implants may lead to bone loss and failure of

implants causing problems ranging from screw

loosening to loss of osteointrigation.3

The adaptation precision, between prosthetic

infrastructure and implant or tooth is one of the

great challenges of oral rehabilitators.4

Impression materials and techniques are

fundamental in precision of fit and passivity of

implant supported FDP’s5. Accuracy of impression

is affected by the selection of impression tray that

might be a stock tray or custom tray. Impression

techniques like close tray or open tray and type of

impression material also attributed to accuracy.

In case of impression procedures, most of the

researchers reported that the open-tray pick-up

technique is more precise and predictable than

the closed tray technique using repositionable

copings6.

A factor that can contribute to the imprecise

transfer of impression copings is a deficient

splinting technique. Theoretically, splinting is

done to prevent the copings from becoming

dislodged during impression making and during tray removal.

Therefore the purpose of this study was to compare

the implant cast accuracy of multiple implants

using different splinting and impression material

combinations.

A reference model with four implants (Bio TEC,

Dental implant system,Germany) in the mandibular

anterior region in overdenture situation were

placed using surveyor for proper orientation of

implants. The implants were numbered 1,2, 3 and

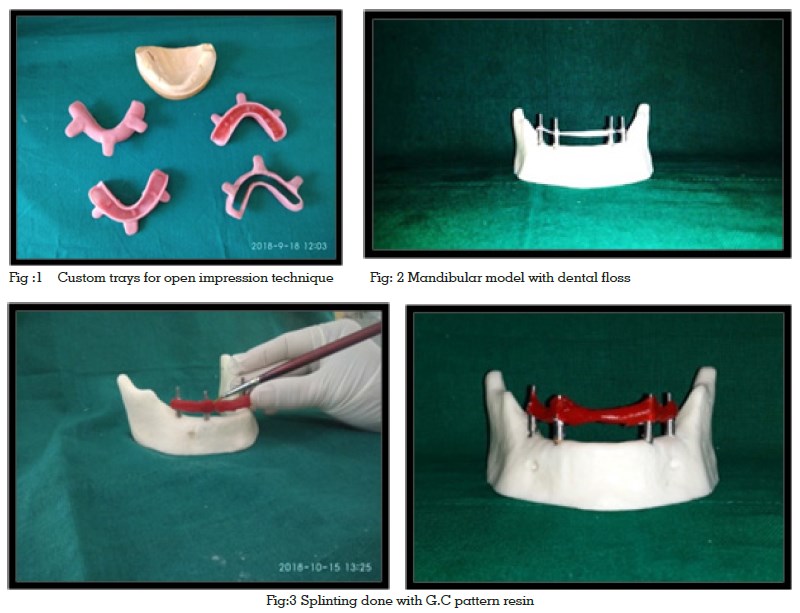

4 for reference purpose. Custom impression trays

were made with autopolymerizing methacrylate

resin (DPI Self cure resin). For this purpose, the

4 implants (Bio TEC, Dental implant system,

Germany) in the model were covered by 2 layers of

wax sheet (Charminar Dental Products, Hydrabad,

India) to allow a consistent thickness of impression

material, and an irreversible hydrocolloid

impression (Alginax, DPI, Mumbai) was made

to obtain a single cast on which all custom trays

were fabricated. Tissue stops were incorporated

between each implant. Three location marks

(circular depressions 2mm wide and 1mm deep)

were made on the base of model and included in

the impression trays to standardize tray positioning

during impression making. Windows were made

in the impression trays for open tray technique to

allow access for the copings screws. (Fig: 1)

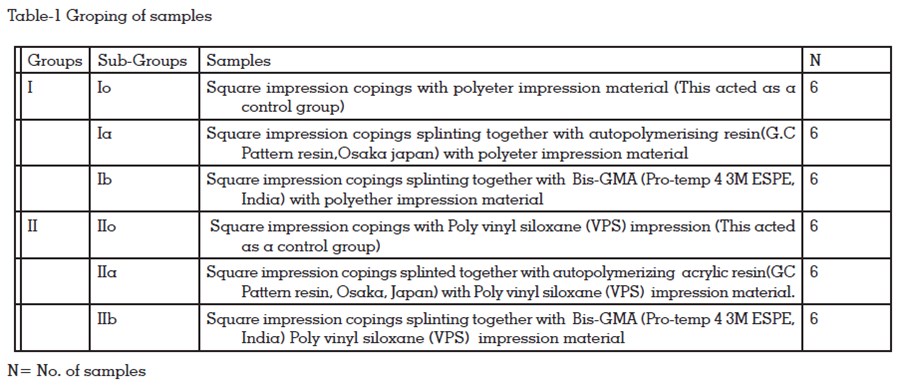

Splinting was done with different materials to

fabricate specimens Group Io samples were

fabricated, with polyether impression material

without splinting square impression copings.

Groping of samples and material details as

follows :

For groups Io, Ia & Ib 18 medium-consistency

polyether impressions (Impregum Penta, 3M

ESPE, Germany) were made. For obtaining

impressions, impression trays were coated with

tray adhesive (Impregum, 3M ESPE) 1 hour before

each impression was made. The impression material was mixed using penta elastomer syringe

(3MESPE pentamix 2 Germany), and part of the

material was meticulously syringed around the

impression copings to ensure complete coverage

of the copings. The remaining impression material

was used to load the custom tray. The custom

trays were fully seated over the resin model with

finger pressure, and the position was maintained

throughout the polymerization time.

In the group Io, impression copings as supplied by

the manufacturer were used (square impression

copings, without splinting) Polyether was used

as an impression material. Each custom tray

was seated, and the material was allowed to

polymerize. The guide pins were released so that

the transfer copings remained in the impression

when the impression was removed.

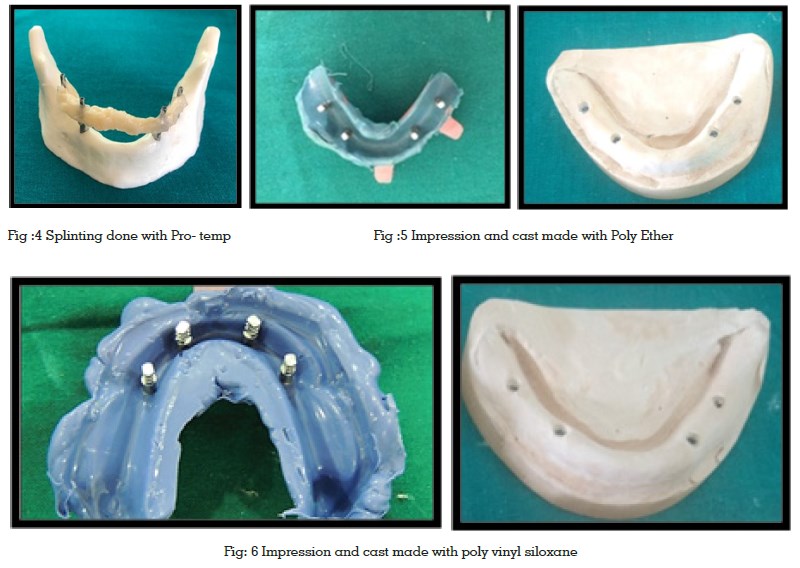

In the group Ia, impression copings were splinted

with autopolymerizing acrylic resin (GC Pattern

resin, Osaka, Japan) .For this copings were splinted

with dental floss (Oral B waxed dental floss, India)

(Fig-2). Autopolymerizing resin (GC pattern resin,

Osaka, Japan) was mixed in the ratio of 2 g–1 ml.

When the resin reached the dough stage, it was

packed around the impression posts and the dental

floss thus they were splinted together. The splint

was allowed to polymerize for 4 min. The splint was then sectioned in between the impression

posts using a thin separating disc to relieve the

stresses caused due to polymerization shrinkage.

The cut sections were joined using the same resin

by applying it using brush bead method(Fig-3).

This was again allowed to polymerize for 4 min.

The impression copings, custom tray, and the splint

were coated with polyether adhesive and allowed

to dry for 15 min. The impression procedure was

accomplished as previously described.

In the Ib group, impression copings were splinted

with Bis-GMA (Pro-temp 4 3M ESPE, India) and

the impression procedure was accomplished as

previously described (Fig-4).

For the open tray technique, the guide pins were

loosened with a hex driver (EZ Hi-Tec, Life Care

Devices) and removed, the tray was separated from

the definitive model, and the impression copings

along with the guide pin remained locked in the

impression. The implant analog was connected to

the hex at the bottom of the impression coping, and

the guide pins were tightened with the hex driver.

In the IIo, IIa, and IIb groups VPS impression

material was used. The procedure for these 3

techniques was the same as for the first 3 groups.

The custom trays were painted with VPS adhesive (VPS Tray Adhesive, 3M ESPE, St Paul, Minn) and

allowed to dry for 15 minutes. The custom trays

were filled with VPS impression material, (Imprint II

Garant, 3M ESPE). The custom trays were seated

on the definitive model, and any excess material

from the open tray windows was removed with a

finger swipe to expose the guide pins.

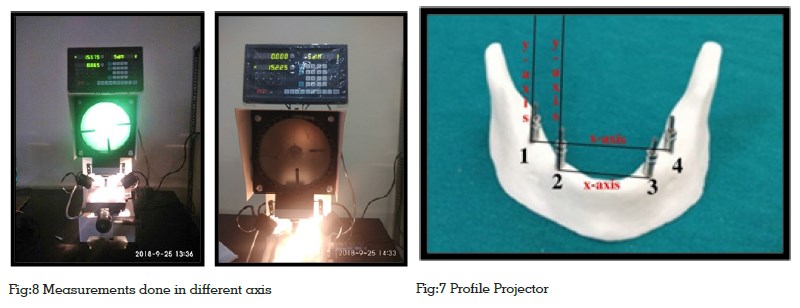

An ADA type IV die stone (Kalrock, Kalabhai Karson

Pvt Ltd, Mumbai, India) was used to pour the

impressions in accordance with the manufacturer’s

instructions. The casts were retrieved from the impressions after 24 hours. All of the casts were

stored at room temperature for a minimum of

24 hours before measurements were made. All

definitive casts were evaluated for the positional

accuracy of the implant replica heads using a

profile projector. A profile projector is an optical

instrument that can be used for measuring linear

dimensions in x and y axis. The projector magnifies

the profile of the specimen and displays this

on the built-in projection screen (Fig-7). All of

the casts were secured to a universal movable

surveyor table (Unident New Delhi,India), and the 3-dimensional position was adjusted so that the

horizontal reference plane of the profile projector

coincided with the plane connecting the highest

points located at the periphery of the 2 implants.

The following measurements were evaluated on the

reference model and the definitive cast replicas:

posterior x-axis (1 and 4); and anterior x-axis (2

and 3), left y-axis (1 and 2) and right y-axis (3

and 4) (Fig-8).

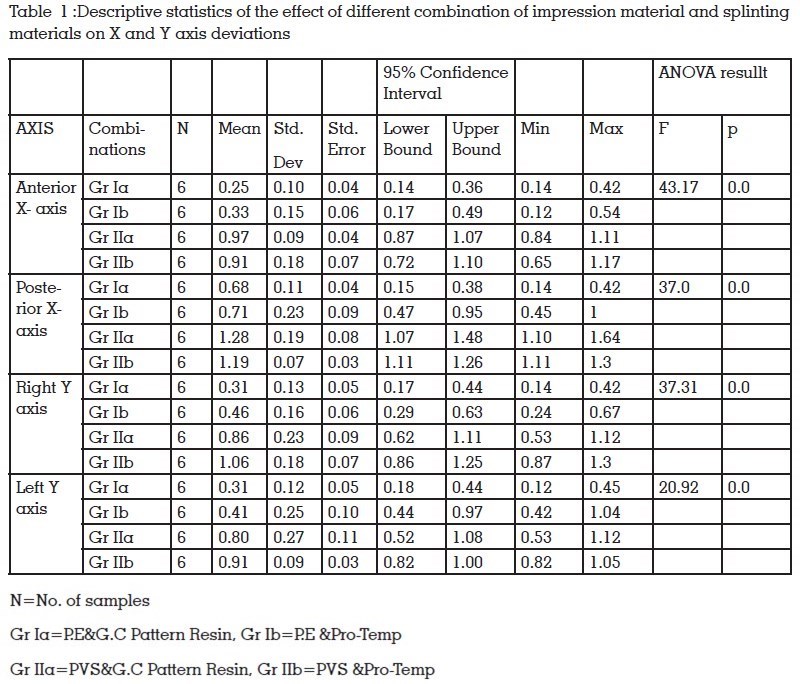

Data were analyzed with 2-way analysis of

variance (ANOVA) followed by Post hoc tukey

In the present study there were a total number of 36 test samples, divided into 2 groups and 4

subgroups of 6 sample each.

From this table it appears that for all measurements,

a significant variation exists in the magnitude of

deviations created by the different combinations of

splinting with impression materials. The interaction

between the combination Gr Ia produced the

minimum variation mean (0.25±0,10) and maximum

deviation with Gr IIa (0.97±0.09) combination. The

deviation obtained with Gr Ib (0.33±15) is closer

to Gr Ia (0.33±45). Gr IIa (0.97±0.09) is closer

to Gr IIb (0.91±0.18). Inter group comparison of

maximum values of variations in anterior x- axis

obtained with all these groups appeared to be

highly significant. This was evaluated with one way ANOVA results appeared to be highly significant

(F=43.17, p≤ 0.00 )

A multiple comparison followed by post hoc

Tukey’s test was performed to assess the extent

of variation made by different combinations in

different measurements revealed that subgroups

comprising of Gr Ia and Gr Ib showed significantly

less variations (p≤0.00) as compared to Gr IIa

and Gr IIb. The results are presented in table 5.

In Implant Prosthodontics, a successful result

can be achieved only when passively fitting

prostheses are fabricated. A passively fitting

prosthesis is a precondition for the maintenance

of osseointegration, and its use is dependent

upon the fact that the bone-implant interface allows limited movement of 10 mm; therefore, it

is unlike natural teeth, which are cushioned in

alveoli by periodontal fibers3. The impression must

be accurate to obtain the resulting master cast

which precisely duplicates the clinical situation.

The accuracy of the implant cast depends on many

factors; the type of impression material, implant

impression technique, the implant angulation,

the die material accuracy, and the master cast.7

Most research indicates that direct techniques

produce less distortion than indirect techniques11.

Polyether and poly vinyl siloxane impression

materials were used in present study as they

are known to provide superior reproduction

in comparision with other impression materials

in accordance with study carried by Sorrentio,

Alikhasi and Martin-Rus8,9,10. Because splinting with acrylic resin has yielded conflicting results.

This is an attempt made to evaluate the reliability

of bis-GMA (Pro-temp 4), and GC pattern resin

as splinting material. Polyether and poly vinyl

siloxane has been advocated as an impression

material for multiple implant -supported prosthesis

for edentulous patients. Both of these were used

as the impression materials. The overall accuracy

of the impression depends on deviation in the

X and Y axis. One of the drawbacks of direct

impression technique is rotation of impression

copings in the impression during fastening of

the implant analog. In X and Y axis both the

Groups I and Group II exhibits no differences

with the reference model. Possible limitations of

the present study design were that the measured

distortion did not completely evaluate the actual

three –dimensional distortion of the impressions.

Only the linear discrepancies in two planes were

evaluated and angular axis discrepancies were

not included in the study. Under clinical conditions

these differences may vary if the discrepancies

are present in other spatial planes .Thus, such

discrepancies may clinically result in a improper

fit of the prosthesis. However the results may vary

in clinical situations, therefore further clinical

studies may be required to evaluate and rectify the

problem in more depth considering the limitation

of previous and our present study to achieve

some other methods for the clinical applications. Only two combinations of impression materials

were included in the study. Further studies may be

conducted using different combinations as well.

The surgical and prosthetic procedures for the placement of implant fixtures require a strict protocol to ensure osseointegration. Prosthesis should have a passive fit; an implant protected occlusion and made of a material which is biocompatible. An accurate impression that will ensure correct three-dimensional spatial orientation of the implant hex is of paramount importance to achieve prosthetic success. This study was conducted to compare the implant cast accuracy of multiple implants made with different splinting and impression materials. The following conclusions were arrived within the limitations of this in vitro study:

Possible limitations of the present study design were

that the measured distortion did not completely

evaluate the actual three –dimensional distortion

of the impressions. Only the linear discrepancies

in two planes were evaluated and angular axis

discrepancies were not included in the study. Under

clinical conditions these differences may vary if

the discrepancies are present in other spatial

planes. Therefore further clinical studies may be

required to evaluate and rectify the problem in

more depth. Only two combinations of impression

and splinting materials were included in the

study. Further studies may be conducted using

other combinations of impression and splinting

materials as well.