In the perfect world things do change. Advances in electronic technology and materials have influenced every aspect in the field of dentistry including prosthodontics. Incorporating these advances into dental practice enables the practitioners to offer a wide range of services and additional treatment options. Among that Rapid Prototyping (RP) techniques, becoming more attractive compared to others advancement. Rapid prototyping processes are fabricated part layer by-layer until complete shape finished from 3D model. Biocompatible materials, such as Titanium and Titanium alloy, Zirconium, Cobalt Chromium, PEEK, etc, are used for fabrication process. Main RP techniques used in Dentistry are Stereo Lithography Apparatus (SLA), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and ink jet printing. This article reviews the changing scenario of technology in dentistry with special emphasis on Rapid Prototyping and its various applications in Prosthodontics.

Novelity is the mother of innovation, advent of CAD-CAM technology has opened up new perspectives for design of production in the field of prosthodontics. CAD-CAM technology has developed to solve 3 challenges. First challenge was to ensure adequate strength of the restoration, especially for posterior teeth. Second challenge was to create restoration with a natural appearance and with good aesthetics. Third challenge was to make tooth restoration easier, faster and accurate. History says that first CAD-CAM were developed in 1960s for use in aircraft and automotive industries. First person to develop a dental CAD-CAM device by Dr. Durett. The developer of the first commercial CAD-CAM system by Dr. Mormann and Dr. Anderson developed the PROCERA system. In CAD-CAM system in dentistry we have two different approaches. They are subtractive and additive. Subtractive technique is usually accomplished by conventional numerical code machining generally milling which can capture only the external surface data of the anatomy and not the internal tissue structure of the proposed object. Hence they are used typically in small model making machines. This is the main reason for using them to fabricate metallic or ceramic crowns in dentistry. On other hand additive technologies which can capture internal as well as external surface of the human anatomy which can produce complex shapes. It is also called as layered manufacturing or solid free form fabrication. According to GPT 9 –Rapid prototyping is a process that creates part in an additive, layer by layer manner.

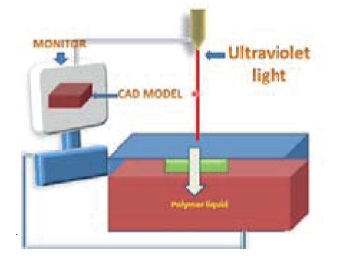

It was first patented by Hull in 1984, which can produce 3D models from photopolymer resins. The parts of stereolithography which includes

Mechanism:

Laser solidfy the layer of polymer liquid, platform will go down carry first layer and laser work on the second layer again and again process will repeated. These layers are formed and fused together to form final model2,3.

Applications:

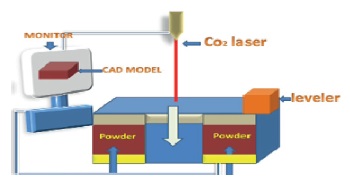

It is a process of fusing together layer of specified powder material into a 3D model by a computer -directed laser. The parts of selective laser sintering includes

Mechanism:

Thermoplastic powder is spread by a roller over the surface of a build cylinder. The piston in the cylinder moves down one object layer thickness to accommodate the new layer of powder. The powder delivery system is similar in function to the build cylinder. Here, a piston moves upward incrementally to supply a measured quantity of powder for each layer. A laser beam is then traced over the surface of this tightly compacted powder to selectively melt and bond it to form a layer of the object. The fabrication chamber is maintained at a temperature just below the melting point of temperature slightly to cause sintering. This greatly speeds up the process. The process is repeated until the entire object is fabricated. After the object is fully formed, the piston is raised to elevate it. Excess powder is simply brushed away and final manual finishing may be carried out.

Applications:

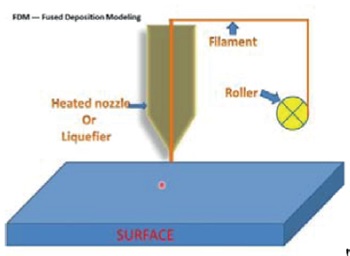

Fused deposition modeling is the second most widely used rapid prototyping technology after stereolithography. The parts of Fused deposition modeling includes

Mechanism:

As the nozzle is moved over the table in the required geometry, it deposits a thin bead of extruded plastic/wax to form each layer. The plastic/wax hardens immediately after being squirted from the nozzle and bonds to the layer below. The entire system is contained within a chamber which is held at a temperature just below the melting point of the material.

Applications:

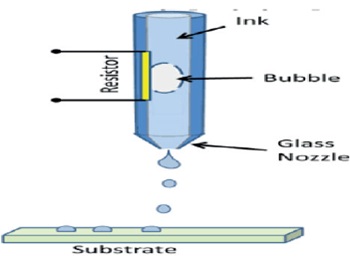

The working principle is basically similar to the conventional 2D inkjet printer. The parts of inkjet printer includes

Mechanism:The liquids are fed to individual jetting heads which squirt tiny droplets of the materials as they are moved in X-Y fashion in the required pattern to form a layer of the object. The materials harden by rapidly dropping in temperature as they are deposited. After an entire layer of the object is formed by jetting, a milling head is passed over the layer to make it a uniform thickness. Particles are vacuumed away as the milling head cuts and are captured in a filter. The working principle is basically similar to the conventional 2D inkjet printer. The process is repeated to form the entire object. After the object is completed, the wax support material is either melted or dissolved away. The most outstanding characteristic of inkjet systems is the ability to produce extremely fine resolution and surface finishes, essentially equivalent to CNC machines.

Applications:

A cleaning unit and a drying device allowed for the build-up of dense components of the size of a posterior crown. A characteristic strength of 763 MPa and a mean fracture toughness of 6.7 MPam 0.5 were determined on 3D-printed and subsequently sintered specimens. The novel technique has great potential to produce, costefficiently, all-ceramic dental restorations at high accuracy and with a minimum of materials consumption10.

In a world that’s becoming increasingly divided on just about everything, there is one thing that we can all agree on-“Esthetics and comfort is of prime importance”. With the digital Sixth sense technology, you can achieve perfection for the patient but also a good comfort through ergonomics. It is not the strongest of the species that survive, nor the most intelligent, but the one most responsive to change.